19

45

45

Return and a new beginning

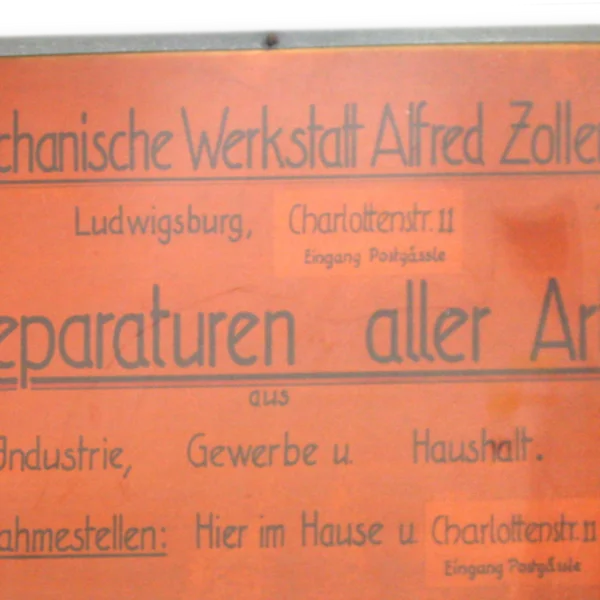

Alfred Zoller returns from Berlin to Ludwigsburg. He had been assigned to Hirth Flugmotoren as a master mechanic for nine years. On September 1, Alfred Zoller establishes his mechanical workshop in Bogenstraße in Ludwigsburg. The Second World War had been over for barely four months. The starting conditions are correspondingly difficult. On the one hand, there is a lot to repair, on the other hand, tools, materials and machines are in short supply.

Fountain pens, lighters, fire engines

Alfred Zoller repairs engines, fire engines, children's toys, fountain pens and whatever else people bring to him. He also repairs defective machines. They are the basis for manufacturing products himself.

His aluminum lighters, which he produces on his lathe, are particularly successful. Over time, American soldiers became his most important customers. They mainly paid for the lighters with cigarettes, peanut butter or chocolate.

19

48

48

Growth and change

Alfred Zoller's company is successfully established in Ludwigsburg. The small company has grown over the past three years and employees have been added. It was getting too cramped in Bogenstraße. The workshop changes location and moves to Charlottenstraße.

Tool holder and further development

Word of Zoller's achievements as a mechanic gets around. The company manufactures tool holders for lathes under license, which are sold through several dealers. These are the first tooling solutions in ZOLLER's history. Alfred Zoller thus has his foot in the door of the turning tool and lathe industry.

Further orders come in from machine manufacturers. Alfred Zoller is to produce sheet metal templates with which turning tools can be set.

19

58

58

The world first: Zoller's setting tool for turning tools

Customers suggest that a presetting device for turning tools would significantly improve production. The imaginative Swabian company Zoller takes up the idea and develops a pantograph for tool setting.

A pantograph is actually a drawing device. But Zoller knew how to use the mechanism in conjunction with a microscope for tool setting. It was the first device in the world that allowed a machine operator to preset all turning tools externally using a technical drawing.

19

68

68

Quick start

Alfred Zoller's son, Eberhard Zoller, joins the company on April 8. The young mechanical engineer works at Heidelberger Druck, a specialist in large printing presses. But his father's health situation requires immediate action. "I felt very comfortable at Heidelberger Druck. It was one of the most modern companies in Germany. But I didn't hesitate for a moment to join my father's company," recalls Eberhard Zoller. His first job was to further develop the presetting and measuring machine.

Change of name

As the focus shifted further towards devices and tool holders, the company changed its name. At the Hannover Messe, the company presented itself as "ALFRED ZOLLER Maschinen- und Vorrichtungsbau".

19

69

69

In series

The setting tool invented by Alfred Zoller and further developed by Eberhard Zoller goes into series production. The company, once founded as a mechanical workshop, becomes a machine manufacturer. By the end of the year, over 30 devices have been sold.

19

76

76

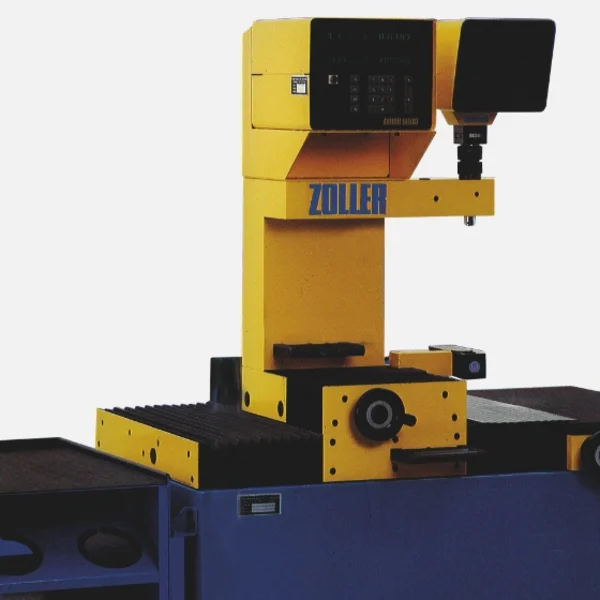

First NC-controlled setting tool

Tool setting is still manual work. This is why ZOLLER is looking for ways to automatically move the tool to the setting position. The world's first NC-controlled tool presetter comes onto the market: the H 4000 from ZOLLER.

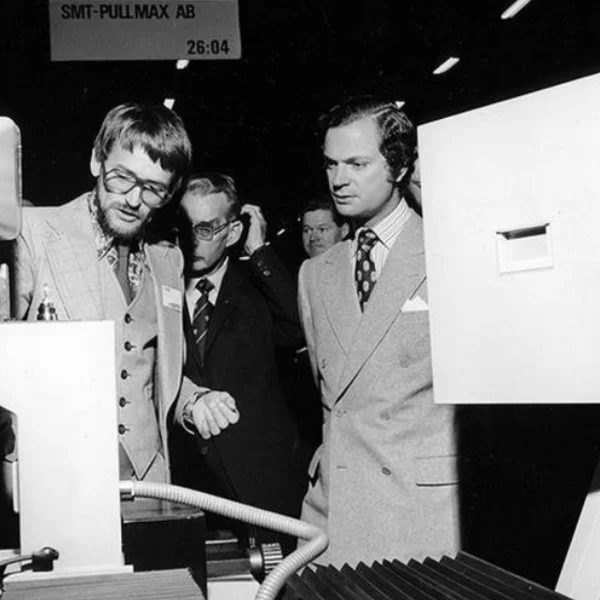

Visit from the king

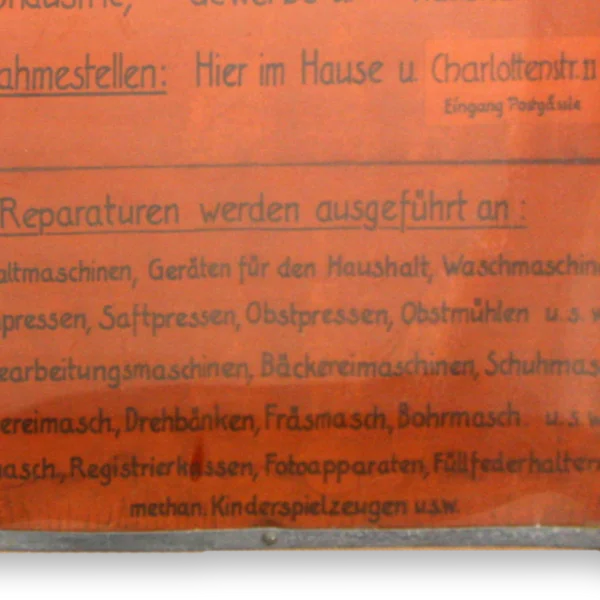

ZOLLER is at the start of a machine tool trade fair in Stockholm. The Ludwigsburg-based company obviously has a first-class reputation in the highest circles. The King of the export partner country himself, Carl Gustav of Sweden, pays a visit to the ZOLLER stand. He wants to know what makes Swabian precision technology so special.

19

77

77

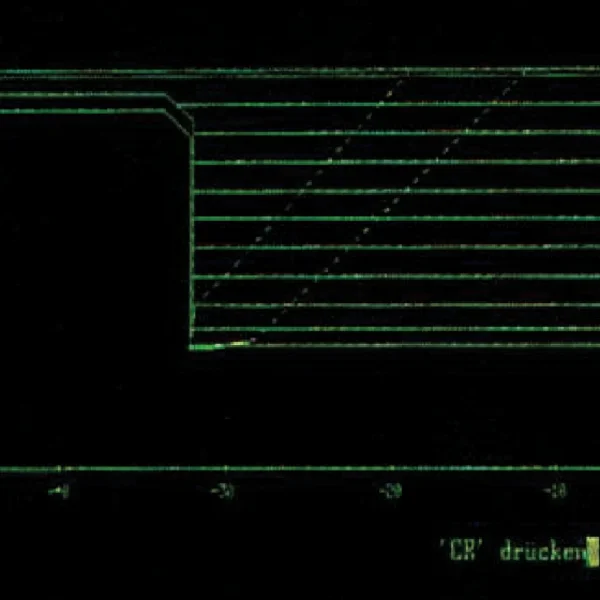

Ahead of the times: With Basic to the digital set-up sheet

For Eberhard Zoller, it is only a matter of time before software becomes increasingly important for processes. There is no question that ZOLLER should develop solutions for this. So, without further ado, the ZOLLER boss becomes a self-taught Basic programmer and presents the first digital setup sheet at the International Hanover Exhibition. The interest is enormous straight away. ZOLLER immediately has a problem: they can't deliver. The boss had intended the program more as a concept sketch. But the seed was planted. Eberhard Zoller hires programmers.

19

81

81

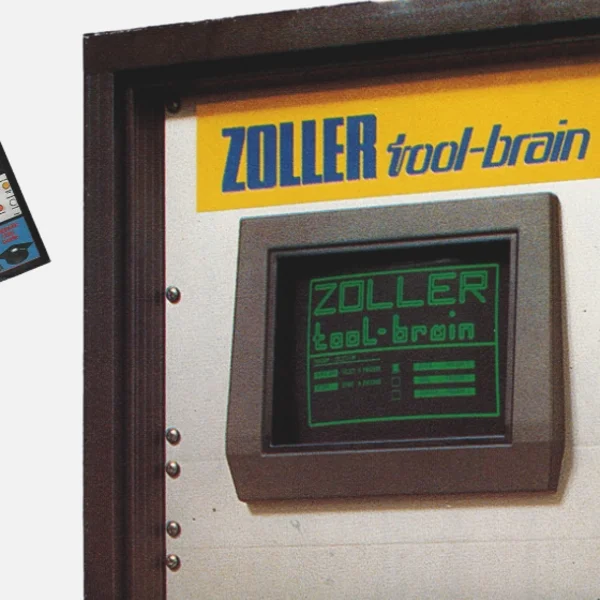

Software for tool processes

Eberhard Zoller wants to be able to digitally map even more tool management requirements. In 1981, ZOLLER presents its first tool management software: Tool Brain.

19

82

82

ZOLLER moves to Freiberg a.N.

The company's next move is imminent, as the space in Ludwigsburg is no longer sufficient for ZOLLER's growth. ZOLLER is building a new facility in Freiberg a.N., creating the ideal conditions for aligning production, development and administration for the future.

19

83

83

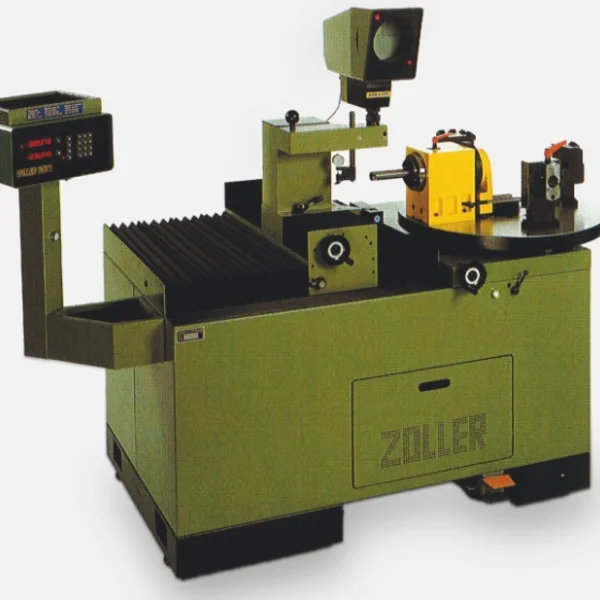

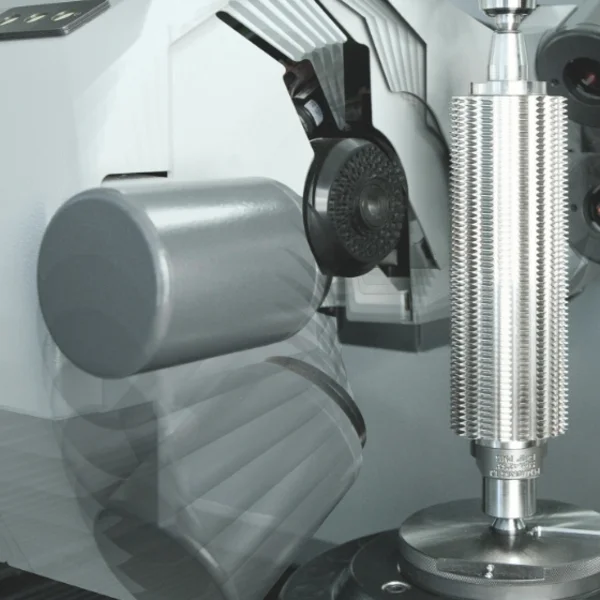

ZOLLER sets the standard for setting tools

The H 1000 manual setting fixture with digital display and D150 mm projector conquers the market. It is the most widely used setting fixture for CNC-controlled lathes of the time. In addition, the first vertical model from ZOLLER comes onto the market: V 1500.

19

85

85

Power Brain replaces Tool Brain

ZOLLER correctly assessed the importance of digital tool management and pushed ahead with the development of the Tool Brain software. The first expansion stage of the software was launched in 1985: Power Brain. The path to the later TMS Tool Management Solutions is mapped out.

19

88

88

Design, ergonomics and operation with distinction

Eberhard Zoller attaches particular importance to ergonomics, simple operation and modular design. For him, these are decisive features with additional benefits that allow ZOLLER to differentiate itself on the market. To this end, he is having the V and H appliance series redeveloped. They are designed to fulfill the aforementioned criteria even better.

ZOLLER is equipping the series with innovations such as the one-hand operating handle and the endless fine adjustment. They make operation much more convenient. For the first time, the company is working with an industrial designer. The effort pays off: the appliances win the HiF International Industrial Design Award and are named "The Best of the Best".

Internationalization increases sales

International sales activities increase, annual sales of presetting and measuring devices climb to 600 units. Subsidiaries in France, Austria and Switzerland are added, as well as many agencies. ZOLLER-Austria becomes the market leader in Austria just ten years after its foundation.

19

89

89

µm-accurate precision for every operator

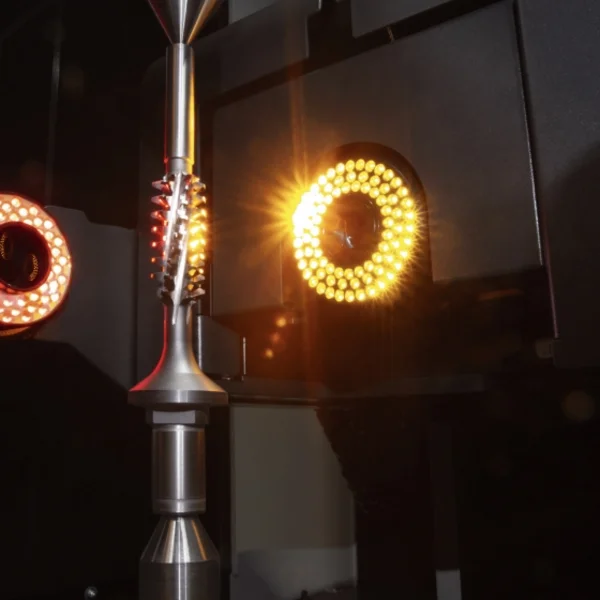

Another technological milestone from ZOLLER: For the first time, an electronic PET projector is being used on CNC-controlled presetting machines. This makes ZOLLER the first manufacturer in the world to offer a system that allows reproducible µm-accurate measurements independently of the operator.

19

91

91

Finger instead of mouse

ZOLLER brings even more convenience to its appliances. Thanks to the new TS 20 and 40 electronics, the touchscreen has been introduced for the first time, making mouse clicks for software operation almost superfluous.

19

92

92

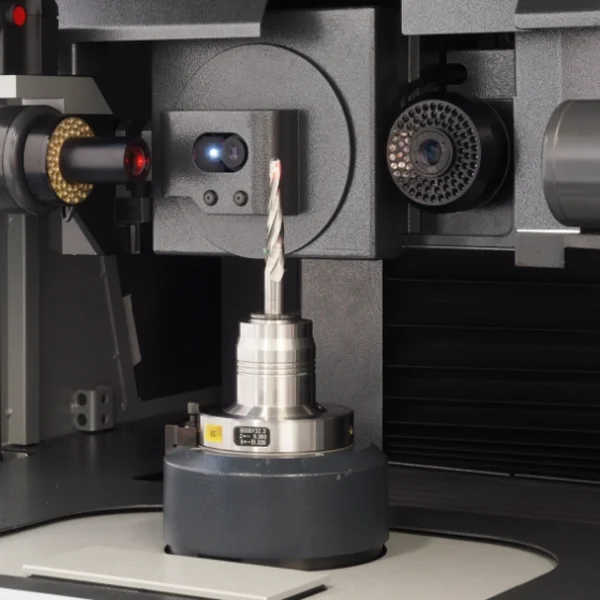

The first ZOLLER device for tool inspection

ZOLLER develops a specialized measuring device with special precision and even more options to meet the high demands of tool manufacturers and grinding shops. The first device is called the H321S and is delivered to the Swabian neighborhood, to Walter in Tübingen. Also integrated: The new GeoTool software including data transfer to the CNC grinding machine.

Economic crisis 1992/93 - sales collapse within months

However, the enthusiasm is dampened. While FAMETA '92 is underway, the automotive industry announces that it will lay off thousands of employees. The economic crisis hits, with far-reaching effects on ZOLLER. "Until September, we had an average of around 50 presetting and measuring machines per month," recalls Eberhard Zoller. "In December, there were still four."

19

93

93

The most difficult decision

During the Christmas break in 1992, Eberhard Zoller has to make one of the most difficult decisions of his entire working life. In 1993, ZOLLER closes its in-house parts production. Because production is outsourced, many employees lose their jobs.

Eberhard Zoller: "That was hard for the people and hard for me. We had a modern production facility with two-shift operation. We were able to load machines with parts and even keep them running unmanned at night. That was now a thing of the past."

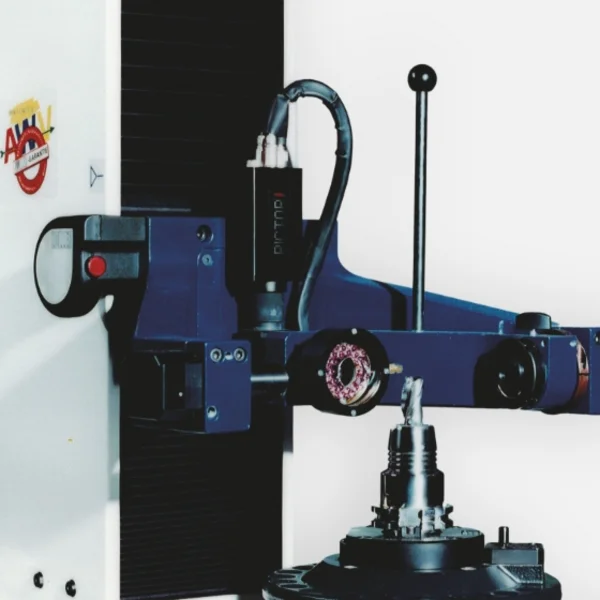

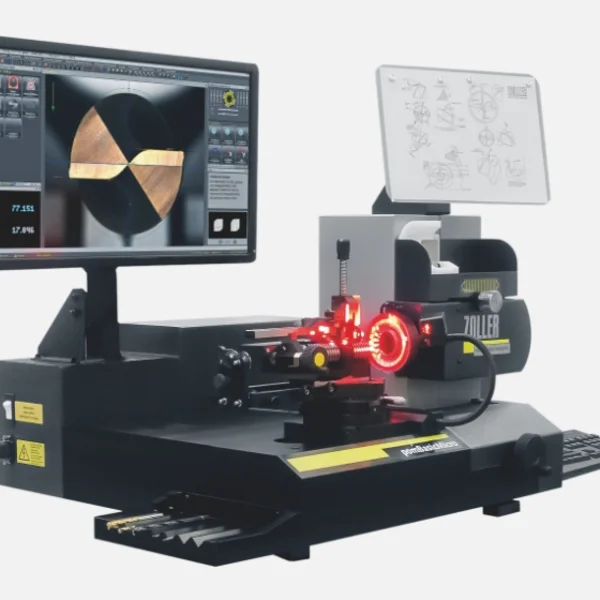

AWV - patented image processing technology

At the EMO trade fair in Hanover, ZOLLER presents its self-developed and patented AWV image processing technology for the first time. ZOLLER attracts a lot of international attention because AWV visualizes the measurement data of a tool in an outstanding way. AWV lays the foundation for industrial metrology via image processing and optics.

19

94

94

KANBAN is coming

The third generation starts at ZOLLER. Eberhard Zoller's eldest son, Christoph Zoller, becomes part of the ZOLLER team. The first project: he optimizes the organization by introducing the KANBAN system in the parts warehouse. An important step towards greater efficiency, which enables ZOLLER to deliver every presetting and measuring machine from the portfolio to a customer within 14 days.

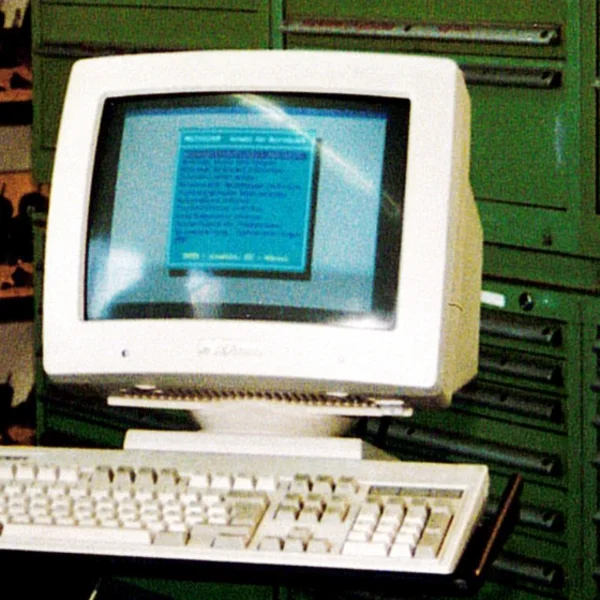

ZOLLER software under Windows

At the AMB in Stuttgart, ZOLLER presents the »Multivision« software with the Windows operating system for the first time. The first measuring machine for tool and mold making for measuring electrodes is also officially presented: »V321combi«.

The newly developed »hyperion« product series and the new »bravo 1/2/3« model series are launched on the market.

19

95

95

The era of »smartCheck« begins

The H321S device for tool manufacturers and grinding stores receives a successor. »smartCheck« arrives, at this time still with a swiveling incident light camera and the »screenMachine« software.

19

96

96

New software solutions

Only 3 years after the initial presentation, ZOLLER presents its customers with the further developed »AWV III« image processing software. The control software for the devices is also new: »saturn«.

19

97

97

Go West - ZOLLER establishes subsidiary in the USA

Until 1997, ZOLLER had the US market looked after by external representatives. With moderate success. After a visit to the IMTS trade fair in Chicago in 1992, Christoph Zoller decides to establish a ZOLLER branch in the USA. Location: Ann Arbor, Michigan, about 60 kilometers west of the former US auto metropolis Detroit. ZOLLER Inc. develops into an important location and today supports not only customers in the USA but also customers in Canada and Mexico.

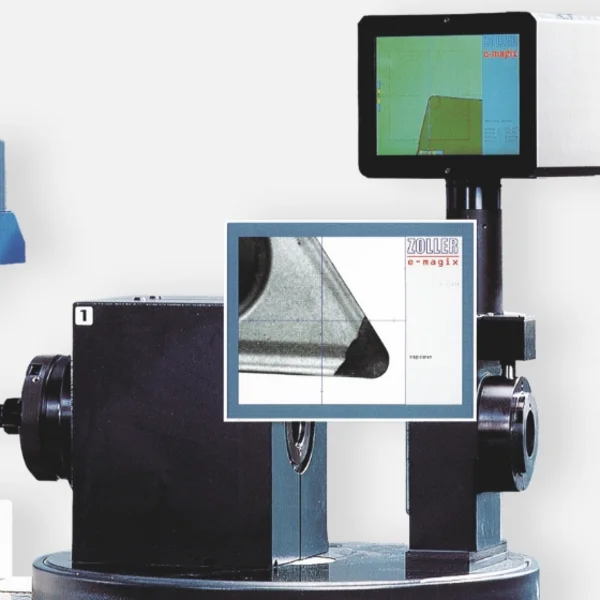

Manual measurements become even easier

"E-Magix" is the name of the new image processing system for manual ZOLLER devices. This means that these presetting and measuring machines are now also ready for operator-independent and µm-accurate measurement. ZOLLER customers with smaller budgets can therefore also benefit from automatic image processing.

19

98

98

New for measuring and testing

At the first specialist trade fair for precision tool manufacturers in Augsburg, Zoller presents its range for measuring and inspecting tools. The »V420 premium«, »V420 profi« and, above all, »the V420 magnum« models with image processing technology are particularly impressive.

19

99

99

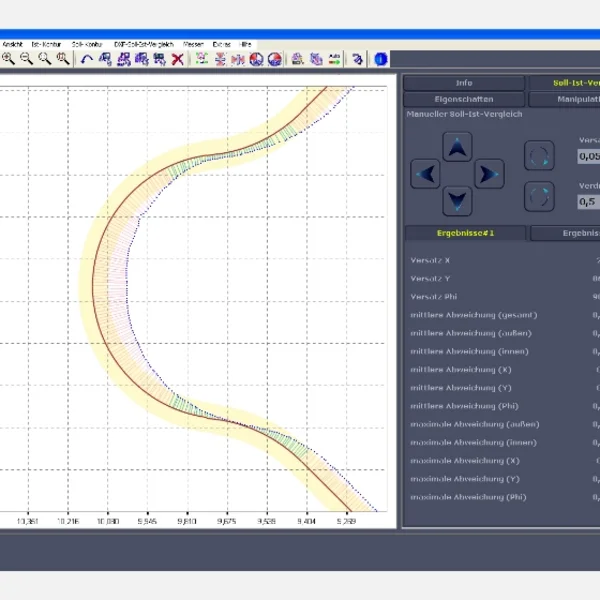

»lasso« captures contours

One piece of software is wowing the experts: »lasso« makes it possible for the first time to scan spiral tools fully automatically on a presetting and measuring machine. In addition, the software can also evaluate shapes and contours with µm precision using a target/actual comparison with a tolerance band based on a DXF target contour. So-called "fir trees" were very popular - especially in the aerospace industry.

20

00

00

The new difference: »smile«

With the »smile« series, the transmitted light projector for manual presetting and measuring devices is finally history at ZOLLER. While competitors at the Intertool trade fair present devices with a projector as a novelty and only from a different source, ZOLLER is once again miles ahead of the market as an innovation driver.

20

01

01

Certified environmental management

ZOLLER takes environmental protection seriously. That is why the company is certified in accordance with DIN EN ISO 14001. This is an operational environmental management system that is internationally recognized through certification.

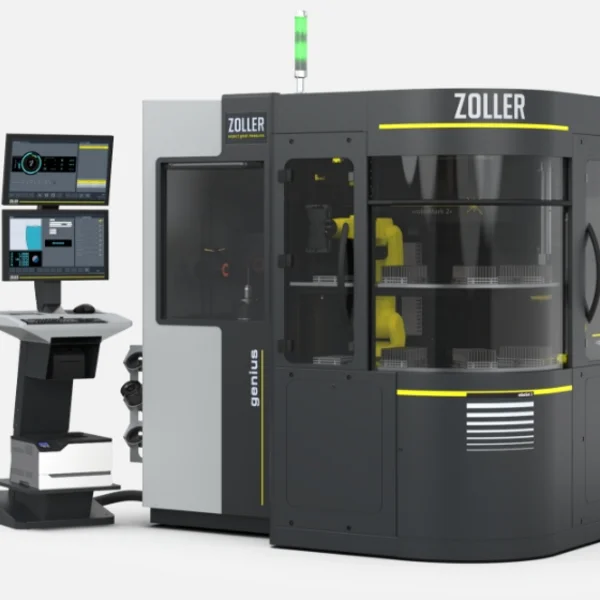

The inspection genius: »genius«

ZOLLER is expanding its technology of presetting and measuring machines with the »genius« measuring and inspection machine. Among other things, the machine offers 5 CNC axes and automatic incident light measurement. This means that ZOLLER can also supply customers who want to automatically record many parameters on the cutting edge and inspect tools for quality with high precision: Tool manufacturers and grinding shops.

ZOLLER will also be presenting other newly developed technological highlights at EMO in Hanover: the »ace« universal spindle, clamping and measuring between centers with »phoenix«, the »zenit« presetting and measuring machine in a seated design for cutter heads and the »gemini« fully automatic measuring machine for crankshaft cutters.

The third generation, Part 2

Eberhard Zoller's younger son, Alexander Zoller, joins the company as an employee in September. He previously completed a dual course of study at the University of Cooperative Education and at ZOLLER.

20

02

02

The shrink expert: »redomatic«

The first order for a device that can be used to shrink and unshrink, measure and adjust tools has been received. What is missing is the right solution. On a car trip to a customer in Switzerland, Eberhard Zoller and developer Christian Pfau discuss potential technical approaches. The trip to the neighboring country pays off. On their return, the design is ready - at least in their minds. Along the way, the two sell three »geniuses« to Switzerland.

»redomatic«, the new setting and measuring device with inductive shrinking technology, is presented at the AMB in Stuttgart. It was just the beginning of shrink technology made by ZOLLER. At the IMTS in the USA, which takes place at the same time, ZOLLER shows the fully automatic »roboToSet« version and demonstrates how the Schunk TRIBOS polygon clamping technology is combined with setting and measuring machines from the V-Series.

20

03

03

More insight with »genius 3«

ZOLLER installs new optics in the »genius 3« measuring machine and presents the »genius Mikro« device. The horizontal machine series " »hyperion" receives a new optics carrier with DME camera, swivel device and quick optics adjustment for even more tool setting options.

ZOLLER Iberica

The foundation of ZOLLER Iberica is completed. This gives ZOLLER a local presence in two new markets: Portugal and Spain.

20

04

04

Retirement is canceled

ZOLLER expands its management team with sons Alexander and Christoph Zoller. The plan is for Christoph Zoller to return from the USA to play a greater role in Freiberg a.N.. Eberhard Zoller largely withdraws from the operative business, as the senior boss had already bought a dog for his retirement. His plan: to go for walks and take care of the four-legged friend's business. But things turned out differently.

Off to China

Christoph Zoller takes off from the USA for China and India. After all, growth markets need a ZOLLER subsidiary. No sooner said than done. He opens a branch in Shanghai and one in Pune. Brother Alexander moves to the USA, takes over the US business and further expands the branch. And Eberhard Zoller? He continues to work for the company - accompanied by his dog.

Measuring in every cutting position

Zoller »aralon« makes it possible for the first time to measure crankshaft cutters with internal cutting edges fully automatically in all cutting edge positions. The measuring device for cutterheads, »zenit«, is supplemented by a portal tailstock with pneumatic clamping of plunge shafts.

20

05

05

Small appliance balance sheet after 60 years

At ZOLLER, the values of company founder Alfred Zoller still characterize the company's inner attitude: reacting quickly to changes, continuously working on innovations and always listening carefully to what customers want.

International customers reward this approach with their trust: Since Alfred Zoller's first machine, ZOLLER had sold around 20,000 more presetting and measuring machines by the end of 2005.

Fully automatic tool inspection

The »genius 3« measuring machine is further developed and fully automatically loaded for the first time. As the »genius 3 sx«, it measures 75 tools of different types loaded into the magazine completely unmanned.

20

06

06

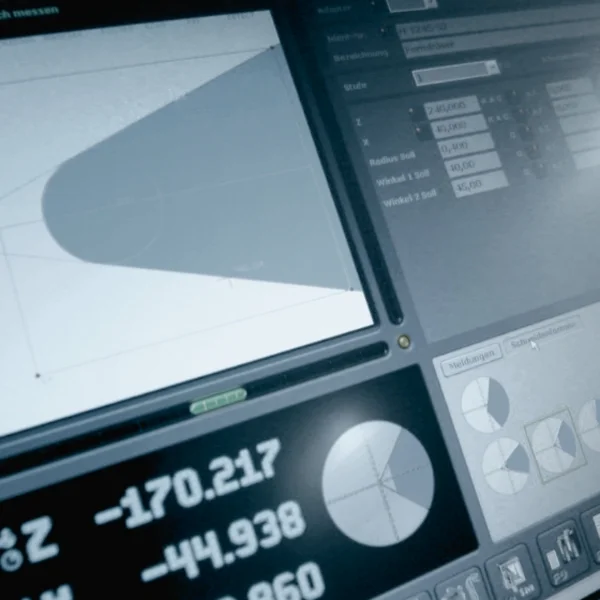

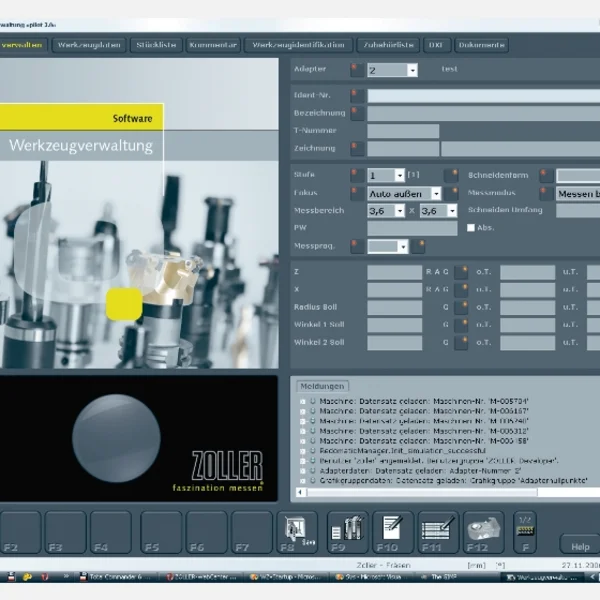

Device software at the highest level: »pilot 3.0«

The »saturn« machine software receives a successor with a new architecture and MMI-optimized, modern interface: »pilot 3.0«.

Zoller is thus setting the global standard for an integrated software concept for presetting and measuring machines, measuring machines, image processing and tool management, including data management and interfaces. »pilot 3« is the ultimate in convenient operation and extremely fast image processing.

20

07

07

»pilot elephant«: Measuring without prior knowledge

At ZOLLER, measuring has to be easy. With the pilot »elephant« assistance software, the company shows that anyone standing at a ZOLLER machine can measure tools with µm accuracy - without a data system and without operating knowledge. It doesn't matter whether an experienced machinist or a vacation jobber is standing at the presetting and measuring machine. Within ZOLLER, this function is known as the "steam hammer".

At EMO, ZOLLER will be demonstrating how the successful »genius« measuring machine can be made even better. »genius« is now equipped with »pilot 3«, has an additional axis and a new microsensor. This enables even greater precision and angle measurements on surfaces - even if the material is transparent.

20

08

08

Relocation to Pleidelsheim

After a good 25 years, the company headquarters in Freiberg a.N. is too small. ZOLLER moves around 4 kilometers further to the other side of the Neckar, to Pleidelsheim.

20

10

10

ZOLLER in Japan

ZOLLER opens its Japanese branch in the megacity of Osaka. The Pleidelsheim-based medium-sized company is thus gradually opening up another important market, with further offices in Nagano and Yokohama to follow.

More space upwards for »venturion«

The setting and measuring devices in the »venturion800« product range now have more space in the Z-direction. Measuring lengths of 1,400 mm and 1,600 mm are now possible on request. The first device is delivered to ZF-Windpower in the USA.

The first virtual measuring device

Also new in the software area: the »CAZ« (computer aided ZOLLER) simulation software. This is a virtual measuring device with which measuring sequences can be simulated during tool design using the 3D model. »caz« is integrated in »pilot« so that the designer can transfer finished measuring routines to a ZOLLER device.

20

11

11

Tool management with ZOLLER

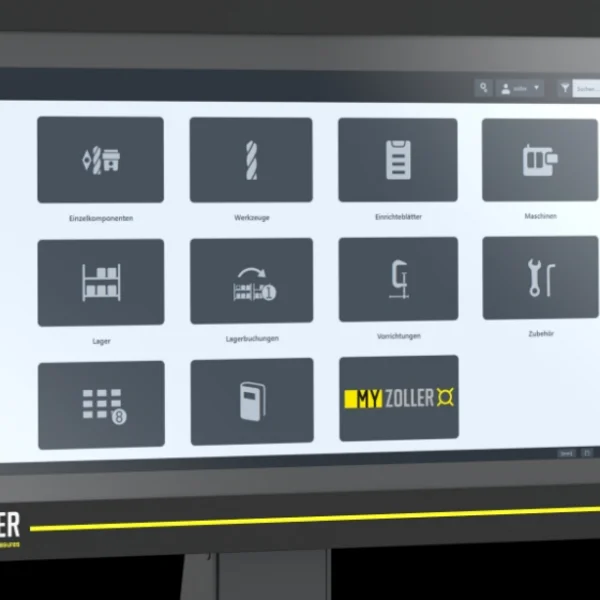

Anyone using tool management software in production has structured tool data at their disposal. ZOLLER introduces the TMS Tool Management Solutions software, bridging the gap between digital tool management and measurement data from presetting and measuring machines and testing machines. Data and data management are growing together.

Fast, process-oriented measurement

ZOLLER launches »pomSkpGo« on the market. It is the first mobile measuring device for measuring cutting edge preparation. ZOLLER thus combines flexibility and high precision in one device. It is the start for devices that are designed for process-oriented measurement. They stand for fast, precise manual measurements at the incoming goods department or for tool checks next to the grinding machine.

Portfolio grows with special applications

Also new: six top specialists for special tool types. In future, customers will be able to use »hobCheck« and »pomZenit« to measure hobs. Those who want to measure saw blades can rely on »sawCheck«, face cutterheads can be measured with »millCheck«, corner cutterheads with »pomZenit« and »hob« cutters fitted with indexable inserts with »hobCheck800« .

For customers in the engine manufacturing industry, ZOLLER is adapting its outstanding measuring technology to the measurement and straightening of crankshaft cutters. The solutions are called »eQick200« and »eQuick 300«.

The needs of tool and mold making are also coming more into focus. ZOLLER realizes »smile EDM« and develops a special assembly with an electronic measuring probe as well as software with a graphical user interface and additional calculation methods.

20

12

12

The measure of what is technologically feasible: »titanium«

The »titan« measuring and inspection machine expands the »genius« series. This machine is the fully automatic high-end solution with up to 7 CNC axes for the µm-accurate inspection of precision tools, including cutting edge preparation. »titan« is a measuring giant with a weight of up to 1,400 kilograms. One that stoically does its precision job in the middle of production.

The reamer expert

In addition to the comprehensive solutions for setting and measuring reamers via image processing, ZOLLER equips the »reamCheck« device with an electronic double probe.

ZOLLER in Great Britain and Indonesia

In December, ZOLLER establishes its subsidiary in the United Kingdom. The ZOLLER UK team is now based in the tranquil town of Foston in Derbyshire. This is almost in the middle of the Birmingham - Sheffield - Manchester triangle. In the same year, ZOLLER opens an office in Indonesia.

The number of presetting and measuring machines sold worldwide climbs to over 30,000 by the end of the year.

20

13

13

Growth for the measuring machines

The »threadCheck« measuring machine rounds off the inspection portfolio with automatic measurement and testing of threading tools.

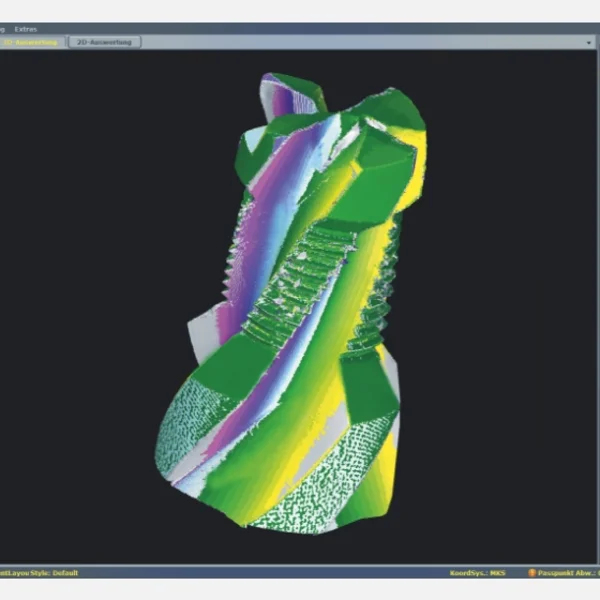

The new »3dCheck« device is based on »genius«, but comes with additional features. It follows the growing trend towards digital twins of tools and the digitalization of workpieces. This six-axis measuring machine not only performs precise tool inspection, but also creates a 3D digitalization from a tool, for example.

The »edgeControl« measuring machine specializes in detecting signs of wear and detecting even the smallest chipping on the cutting edge without contact.

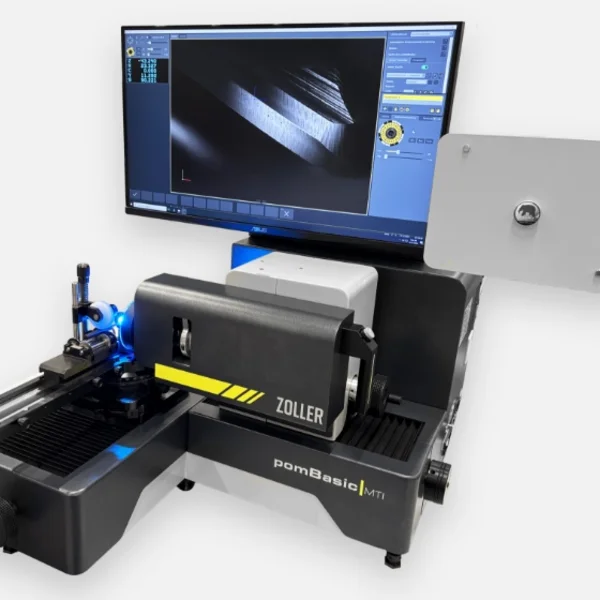

Further devices for process-related measurement

The POM series receives three extensions. ZOLLER is presenting its customers with the new universal devices »pomBasic« and »pomBasic micro« for the in-process measurement of standard and micro tools. With »pomDiaCheck«, a special device is being launched that can be used close to the process and measures the diameter of round-ground blanks as well as drilling and reaming tools to an accuracy of less than 1 µm.

CNC technology for »redomatic«

The combined device for shrinking, setting and measuring shrink fit tools to the exact length now measures fully automatically. Apart from inserting the components and removing the finished complete tool, the operator takes on the role of spectator.

Certifications

ZOLLER introduces DIN EN ISO 17025 and is recertified in quality management in accordance with ISO 9001:2008, VDA 6.4:2005 and the environmental management system ISO 140001:2004.

20

14

14

More efficiency for tool manufacturers through automation

At the GrindTec trade fair in Augsburg, ZOLLER will be demonstrating how tool manufacturers and grinding companies can automate tool inspection. »roboSet 1« handles all tool handling processes for the »genius« universal measuring machine. Complete tool batches are inspected fully automatically and the results are documented.

Also new: solutions for the fully automatic measurement of special drill geometries and types, such as KENtip , as well as software for measuring grinding wheels.

Continuous, automated data transfer

Entering tool data by hand is a thing of the past. ZOLLER is presenting »zidCode« for the first time at EMO in Milan. This new ZOLLER solution transfers tool data to the CNC machine directly, error-free and in line with the control system. Simply scan the code on the tool.

For ZOLLER, «zidCode« is an important innovation, as it enables production to run digitally throughout the entire CAM-to-part process with immediate effect.

20

16

16

The big update for »smile« and »venturion«

The tried-and-tested »smile« and »venturion« series of setting and measuring devices are being relaunched. Even more precision, even easier operation, even more convenience. Whether a skilled or semi-skilled person presses the buttons on a »smile« or »venturion« is almost irrelevant.

Maximum support is provided by CNC control, »pilot« device software, autofocus, the separate »cockpit« operating unit, »elephant« assistance software and the new »eQ« one-hand operating handle. ZOLLER proves that the most user-friendly precision machines come from Pleidelsheim.

20

17

17

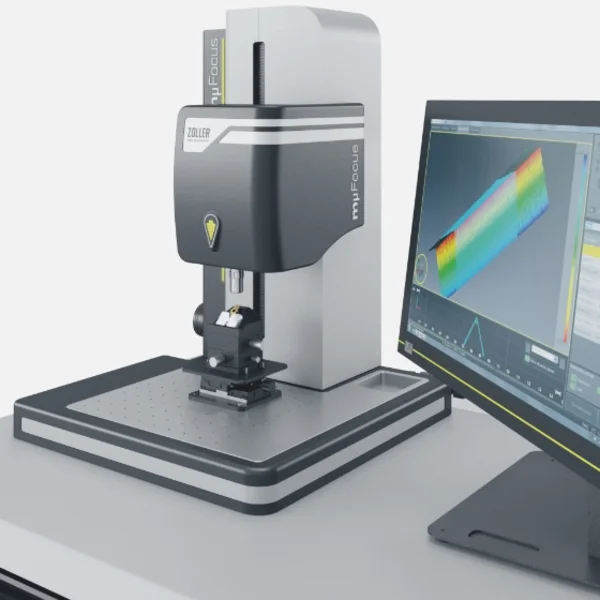

Precise analysis of the tool surface

The near-process inspection device »mµFocus« allows tool manufacturers to view the roughness of the surface on the cutting edge in great detail - without contact. With its high-resolution optical system and »pilot« 's outstanding image processing, »mµFocus« creates color-coded images. They make the smallest nicks and grooves visible.

Tool management hardware expands tool management

Many ZOLLER customers are already using TMS Tool Management Solutions, the modular software for tool and tool data management. Now comes the matching hardware: the large tool cabinet »keeper«, the cabinet for tools and small parts, »toolOrganizer«, and the assembly station »toolStation«. All can be combined directly with the ZOLLER software.

20

18

18

Headquarters in Ann Arbor, new building in Japan

After more than 20 years of market development in the USA, ZOLLER Inc., the US company of ZOLLER, moves into the newly built headquarters in Ann Arbor, Michigan. Alexander Zoller lays the foundation for the new ZOLLER design in the construction industry. The large and comprehensively equipped showroom quickly becomes the hub for customer meetings, training courses, presentations, in-house events and success in the USA.

Zoller also strengthens its presence in Japan. The company moves into its own building.

New automation for models in the »genius family«

After just five years, the successor to »roboSet 1« arrives. »roboSet 2« from ZOLLER integrates a cleaning and labeling station into the automation solution for »genius«. Even more essential process steps in tool inspection and documentation can now run unmanned.

Automation for tools with collet chucks

Zoller is developing another world first for the automatic measurement and setting of collet chucks, among other things: »torqueMatic«. The setting and measuring device can automatically loosen the clamping nut and tighten it again after setting with torque monitoring.

Supplemented by a screwdriving station with torque monitoring, »venturion 450« becomes the new »screwMatic«. The loosening and tightening of Schunk TENDO hydraulic chucks is now automated.

20

20

20

New building with Smart Factory and Academy

ZOLLER is opening a new chapter with the expansion of the company headquarters in Pleidelsheim. A customer center with development, assembly, shipping and administration is being created. The ZOLLER Academy will have modern and spacious rooms in the new buildings. The centerpiece is the Smart Factory, where ZOLLER can present its networked solutions for Industry 4.0 for the first time.

First-class software made even better

The »pilot 3.0« machine software with its outstanding image processing is regarded as a global benchmark. Nevertheless, ZOLLER has set itself the goal of making the tried and tested even better. The successor, »pilot 4.0«, comes with a new interface that is geared towards smartphones and tablets. The convenient operating concept of »pilot 3.0« has been retained. However, users now have the option of customizing their working environment and calling it up on any ZOLLER device. »pilot 4.0« means maximum convenience, high user-friendliness and even easier working.

New machine platform and new design

All Zoller tool measuring machines in the »genius« series have been placed on a new platform and redesigned from the ground up. In addition to state-of-the-art technology, unique ergonomics and vibration decoupling, »genius«, »threadCheck«, »edgeControl«, »3dCheck« and »titan« have a new design.

Expansion for shrinking technology and even greater convenience in data handling

The »redomatic mst« adds another technology to the shrinking product line.

With »zidCode 4.0«, a supplement to »zidCode« is being launched on the market. »zidCode 4.0« is fully networked and bidirectional. It can retrieve data from the central z.One database and transfer it to the CNC machine controller, but can also write updated data such as tool life back to the database.

New building also in China

16 years after Christoph Zoller started business in China, ZOLLER opens its new building for the Chinese subsidiary. A milestone on a long but successful path in international business.

20

21

21

Tool automation for production

System provider ZOLLER will be showcasing new developments that customers can use to automate tool processes and gradually transform their production into a smart factory.

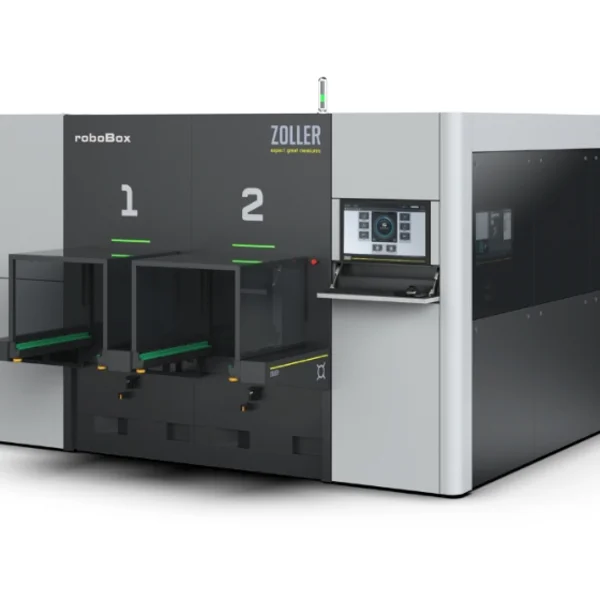

»loadBox« automates the picking of tools, while »roboBox« is the modular automation system for tool assembly, setting and measuring, cleaning, shrinking and unshrinking and other tasks. The versatile »cora series« covers tool handling, cobot assistance and store floor logistics.

ZOLLER benefits from the long-term orientation of its solutions for setting & measuring, checking & measuring, tool management, software and data transfer. Everything comes together for automation.

The new generation of tool holders - with »idChip«

What began in 1948 with holders for turning tools is being taken up again after 73 years: »Tooling«. With first-class tool holders "Made in Germany" and clever accessories, customers worldwide now also receive clamping devices in the familiar ZOLLER quality.

The likewise new »idChip« makes the tool holders immediately ready for tool management with ZOLLER. The coded plastic chip is integrated into the tool holders and makes them clearly identifiable. However, the costs are far lower than those for RFID transponders.

20

22

22

Innovations for balancing and shrinking

ZOLLER has been offering balancing and shrinking solutions for 20 years. However, the requirements have evolved. Time for something new.

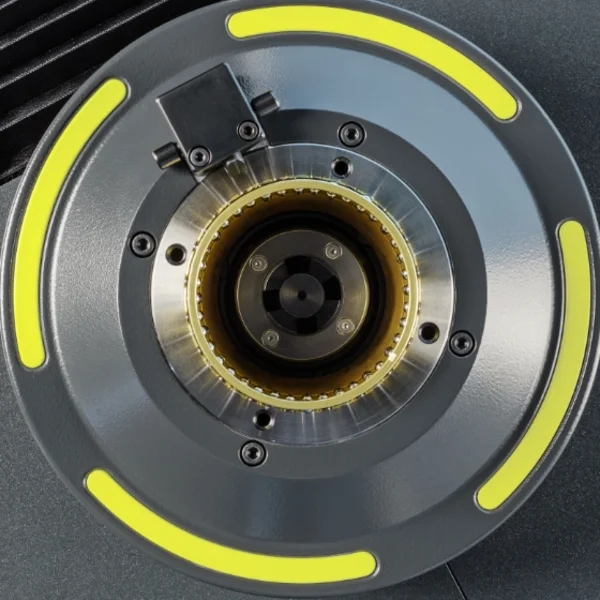

With »toolBalancer« and »powerShrink«, ZOLLER has succeeded in creating two new developments that take precision, energy efficiency, safety and ergonomics to an unprecedented level of quality.

Never before has balancing tools been so easy and so precise. Never before have production employees been able to carry out shrink-fitting and unshrink-fitting processes so quickly and efficiently.

For both solutions, ZOLLER has broken completely new technological ground and underpinned its outstanding capacity for innovation. The trade visitors at the AMB in Stuttgart and at the IMTS in Chicago were amazed at the precision, speed, ergonomics and design of the new machines.

20

23

23

»coraMeasure LG«: The portal solution for automated setting and measuring

Tool automation with a compact portal, without a robot arm - this was the brief Alexander Zoller set his developers. When ZOLLER presented the result for the first time in Germany at EMO 2023, interest was immediately high. »coraMeasure LG« is another innovative approach from ZOLLER to quickly solve a current challenge: Skills shortage.

Entering a new industry

Zoller measurement technology is making its way into the stone processing industry. The new »ConDiaZ« makes measuring and data optimization for the special moulding tools used in this industry child's play. The highlight: AI helps!

20

24

24

The new measuring machine

Welcome, »threadCheck I cc«. The new measuring machine measures, among other things, threading tools for the first time in a fully enclosed and vibration-decoupled unit. Even more precision for the metrological differentiation of crucial details. The integrated and CNC-controlled tailstock can be loaded automatically.

Storing tools safely

The »toolOrganizer« tool cabinet now has another option: »smartCompartments«. These compartment locks developed by ZOLLER extend the already high functionality of the tool management hardware.

For stone and wood

With the »smile gbo« and new large-screen optics, ZOLLER enables its customers to quickly measure complex geometries on stone and woodworking tools in a single step.

20

25

25

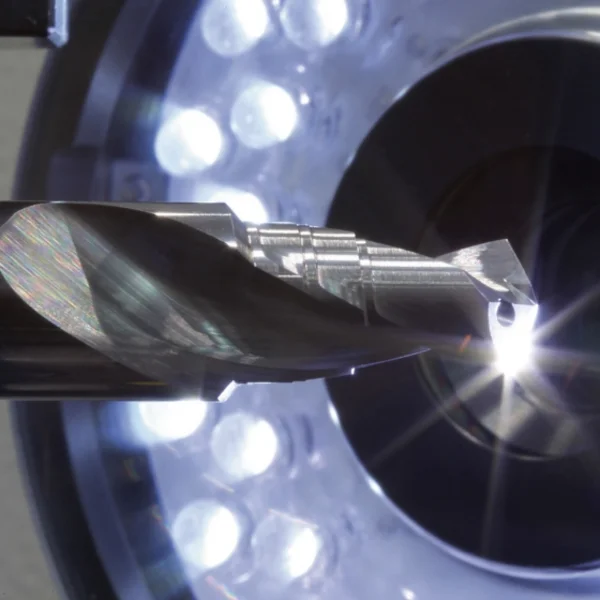

Comprehensive care of the »pom models«

ZOLLER is fundamentally revising the successful »pomBasic« series of process-oriented inspection devices. New models have been added: »pomBasic Compact« and »pomBasic MTI«.

This represents a huge leap forward, particularly for the micro-tool sector up to D=0.1 mm. Special optics and software functions make microscopically small geometries visible and measurable. Fully automatic measurement also becomes a reality with »3dCheck micro«.

Focus on wear testing

ZOLLER intensifies the complex topic of wear. The development of »edgeControl« is progressing rapidly. The ZOLLER development team is working on software optimized for wear testing.

Automation in the parts warehouse

At the beginning of January, in its 80th anniversary year, ZOLLER continues to focus on the future. In the second week of the calendar year, the automated small parts warehouse goes into operation in the assembly department in Pleidelsheim. The system automatically manages more than 18,000 parts and issues what is needed to the assembly department. "This is a milestone for the company. Even at the age of 80, we are committed to constantly modernizing and keeping up with changes," says Eberhard Zoller.