With just one presetter and measuring device, you can save time and money with every tool change. Combined with TMS Tool Management Solutions, you open up further options to reduce costs.

Measured and set tools reduce machine downtime by at least 15 %. You save at least 15,000 euros per CNC machine, year and shift. This is why ZOLLER presetting and measuring machines pay for themselves within a short period of time.

Calculate the savings potential for your production now with the ZOLLER profitability calculator.

profitability calculator

Stellen Sie die passenden Werte für Ihr Unternehmen ein und erfahren Sie, wie viel Geld Sie mit ZOLLER-Geräten in Kombination mit TMS Tool Management Solutions einsparen können. Am Ende zeigen wir Ihnen die Amortisationszeit für die Investition in Ihr Einstell- und Messgerät.

Ihre Einsparung/Jahr mit einem ZOLLER Einstell- und Messgerät

testZusätzliche Einsparung durch ZOLLER TMS Tool Management Solutions

Total savings with ZOLLER

Amortisationszeitraum für das Einstell-und Messgerät

Simply more profit

The economic efficiency calculation is based on the following parameters:

ZOLLER guarantees you savings of at least €15,000 per machine, year and shift if preset tools are used

According to a study by RWTH Aachen University(Rheinisch-Westfälische Technische HochschuleAachen), tool costs amount to 10% of the machine value per year

With ZOLLER TMS Tool Management Solutions you can increase your productivity by at least 5%.

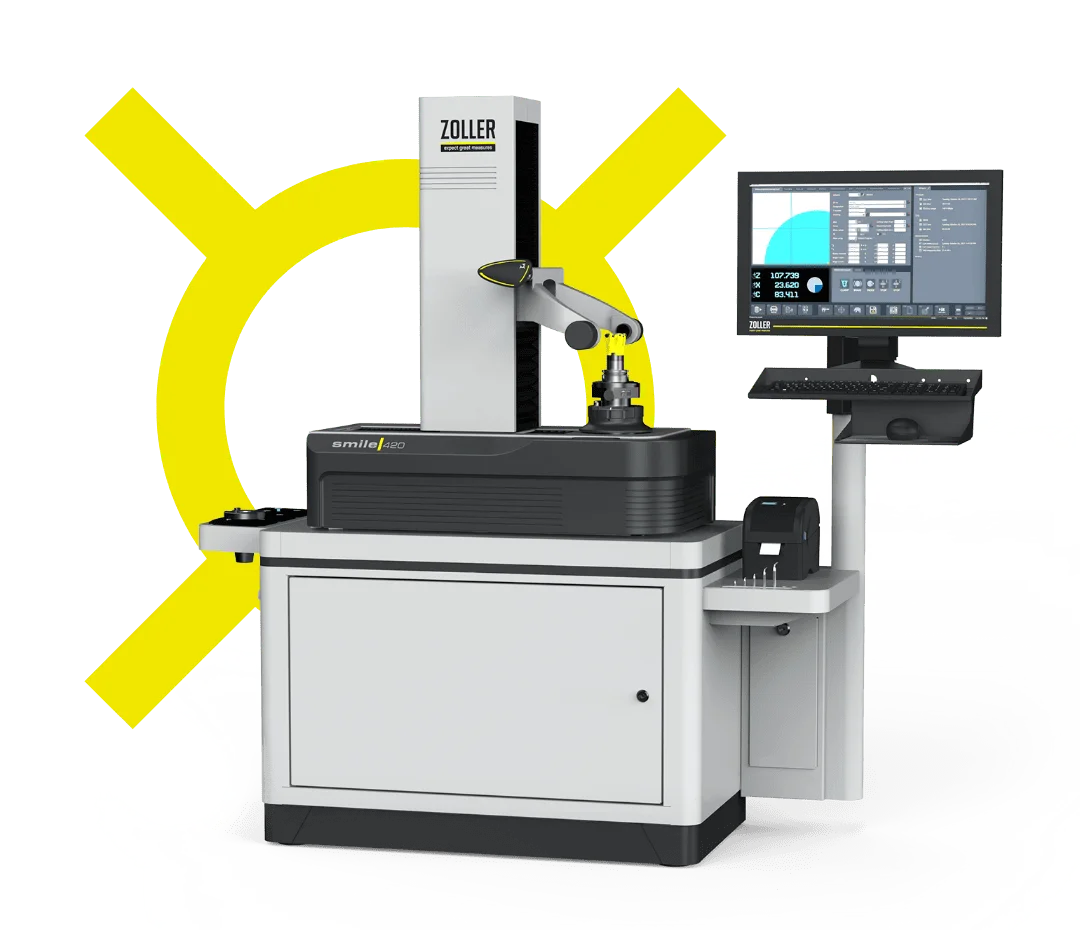

How ZOLLER presetting and measuring machines optimize machine utilization

4.52 minutes of machine downtime per hour and machine are caused by tools that are insufficiently adjusted, measured and prepared on the machine. This is the result of measurements in the automotive industry.

A ZOLLER presetting and measuring machine decisively changes the situation. Every measurement is fast and precise. All tools arrive at the machine perfectly prepared. Machine downtime decreases, main time increases - the time gains add up over the year to a measurable increase in productivity.

For the example calculations, we have reduced the time loss determined in the automotive industry to 3 minutes per hour and take into account 15 to 25 tool changes per day.

Calculation formula per machine:

Time saving in minutes x tool change x shifts x hourly rate

TMS Tool Management Solutions ensure 5% more productivity

With tool management software such as ZOLLER TMS Tool Management Solutions, you can increase your productivity by at least 5 % - this has also been shown in studies by RWTH Aachen University(Rheinisch-Westfälische Technische HochschuleAachen). With the help of your machine hourly rate, you can determine what this increase in productivity brings to your company - in hard cash and per machine!

Calculation formula:

8 hours/day x shifts/year x hourly rate x 5%

2 % less tool costs per year

Studies by the RWTH Aachen University(Rheinisch-Westfälische Technische HochschuleAachen) show that the tool costs for a machine tool in ten years are the same as the cost of the machine itself.

With ZOLLER TMS Tool Management Solutions you can save 20% of these tool costs - that's 2% of the machine purchase price per year in savings! A glance at the tool costs in your company's annual balance sheet will show you the extent of your savings potential.

Calculation formula:

Machine costs x 2%