We stand for smart progress

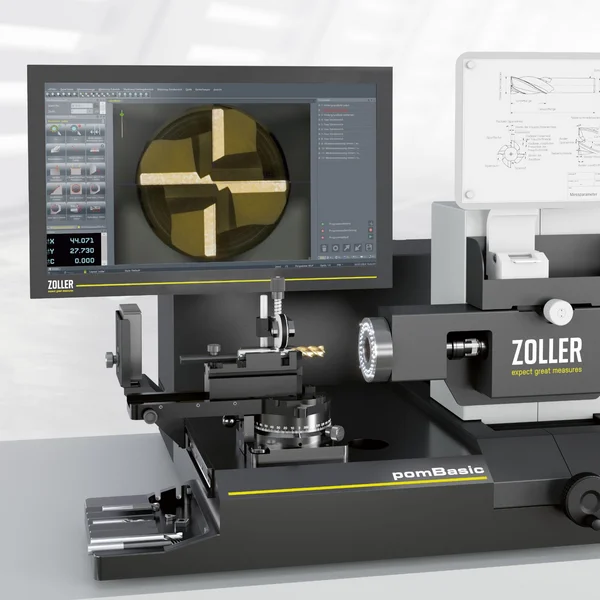

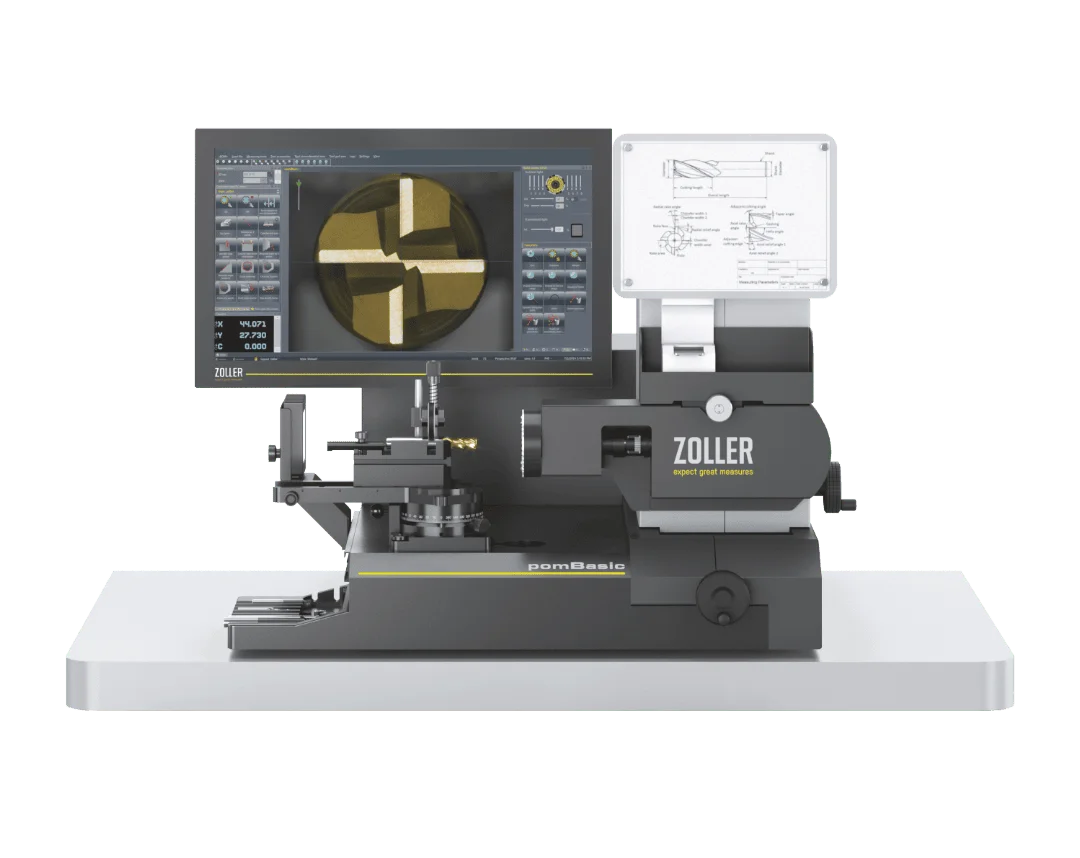

Want to speed up your work processes? Then take an abbreviation when it comes to tool measurement and inspection. The ZOLLER »pomBasic« and »pomBasicMicro« inspection units are the ideal solution.

Save yourself unnecessary trips to the measuring room – benefit from efficient processes and precise results in record time. With their compact dimensions, the ZOLLER »pomBasic« and »pomBasicMicro« inspection units can be positioned anywhere in the production area.

Compactness in detail

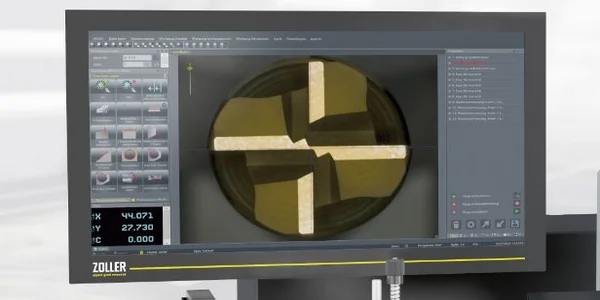

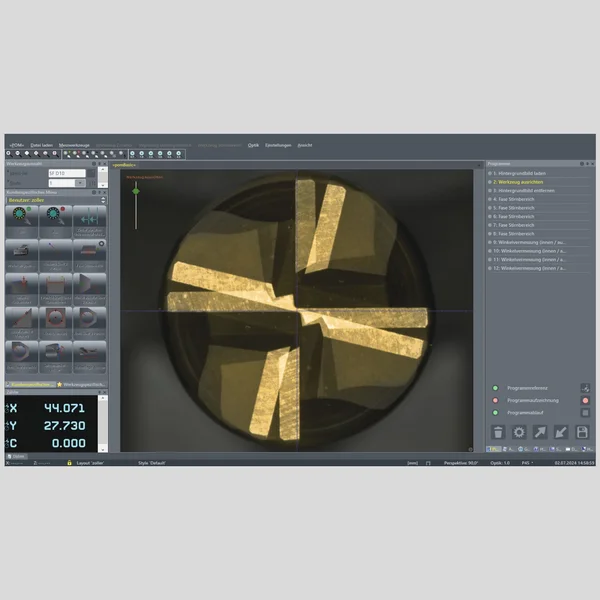

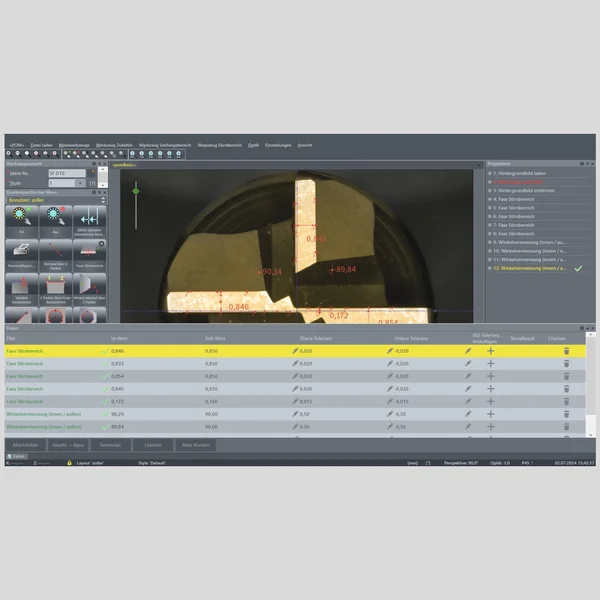

Software »pomSoft«

»pomSoft« software

»pomSoft« software - is self-explanatory, clearly laid out and enables the operator to take reliable measurements. The 24" TFT color monitor impresses with its industry standard and its integration directly on the device.

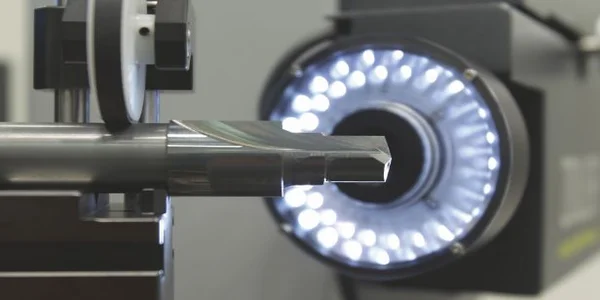

Incident light camera

Incident light camera with multi-LED segment lighting

Incident light camera with multi-LED segment illumination - features centered, dimmable illumination with automatic illumination control. The high-performance LEDs segmented into eight areas ensure optimum illumination of the surface - for high precision.

Additional lighting diffuser

Additional lighting diffuser

Additional lighting diffuser - enables transmitted light measurement in the circumferential area. This allows external contours, step lengths, point angles and much more to be measured.

Tray for mouse and keyboard

Mouse and keyboard tray

Mouse and keyboard tray - is a space-saving, pull-out drawer that is ergonomically positioned on the underside of the desk.

Color laser printer

Color laser printer

Color laser printer - for protocol and list printing, has its place in the practical under-desk.

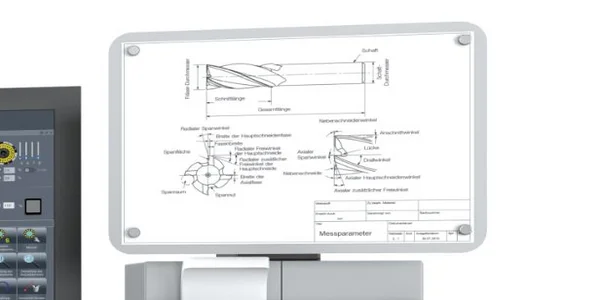

Drawing holder

Drawing holder

Drawing holder - is ideal for attaching drawings in the immediate vicinity of measurements. The magnetic ball-and-socket joint allows flexible and optimum alignment for the operator. The drawings can be easily fixed and quickly changed using magnets.

Integrated electronics unit

Integrated electronic unit

Integrated electronics unit - with professional electrical installation of high-quality components for maximum reliability and a long service life. The electronics unit also offers service-friendly maintenance access.

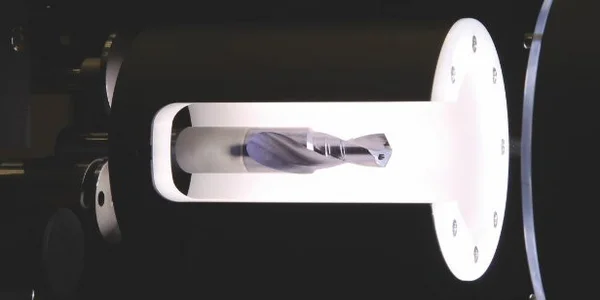

»pomLightTube«

Additional lighting »pomLightTube«

Additional lighting »pomLightTube« - ensures high-contrast illumination of the tool cutting edge in incident light with the LED lighting tunnel. In addition, an optional 2-fold spotlight can be attached to perfectly illuminate concealed tool geometries.

Document and accessory tray

Document and accessory tray

Document and accessory tray - in the under-table provides sufficient storage space and convenient access to your documents and accessories.

Automatic inspection

If you have repetitive measuring tasks and want to carry them out effectively, ZOLLER has the perfect solution: thanks to the macro function, repeat measurements can be saved easily and reliably.

A single click on your saved macro program is all it takes and the measuring process runs automatically: simple, fast and user-friendly.

Fact check for tools

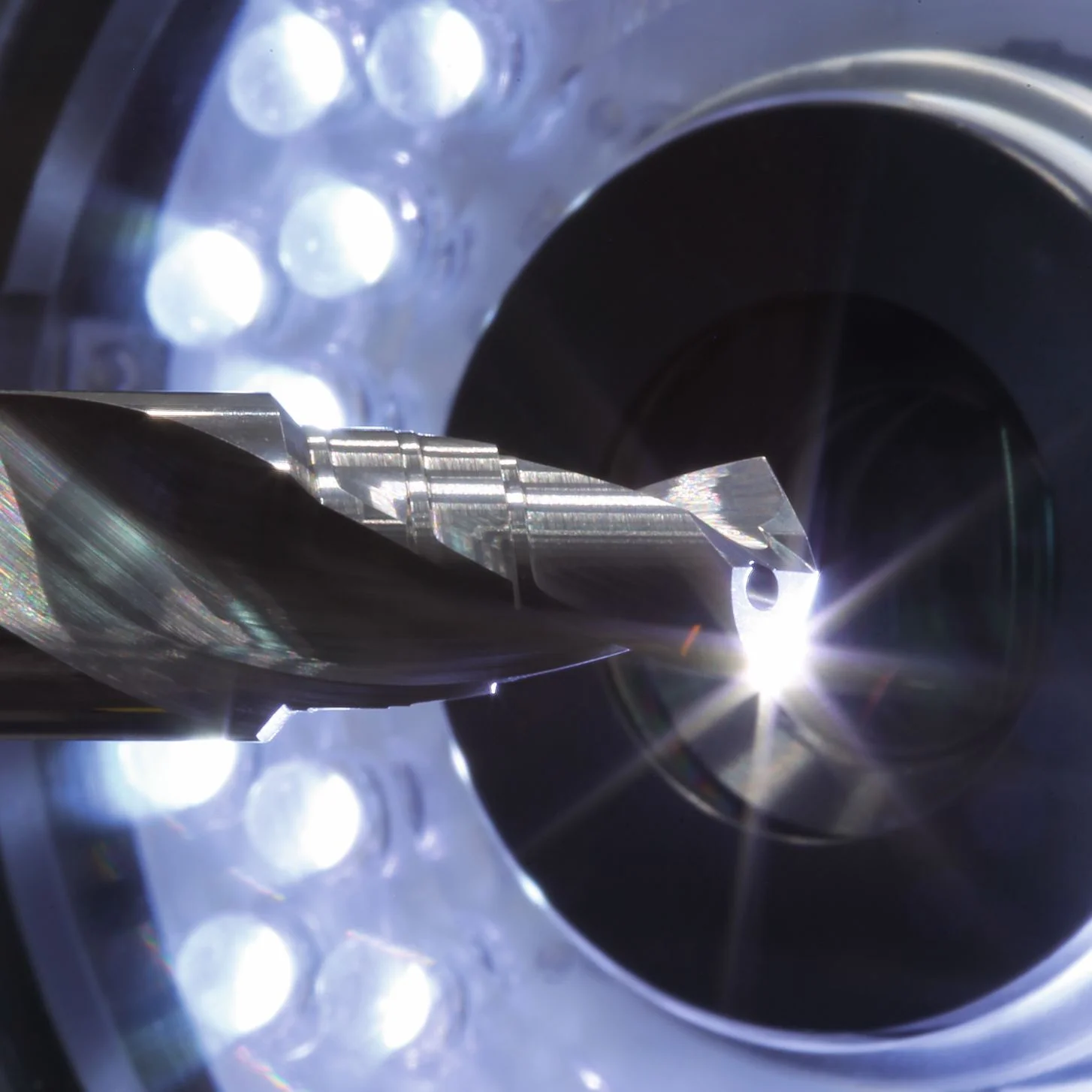

Quality is measurable. That's why it's provable. For tool manufacturers and Grinders, there is a very simple way to provide hard evidence of tool quality: testing and measuring technology from ZOLLER.

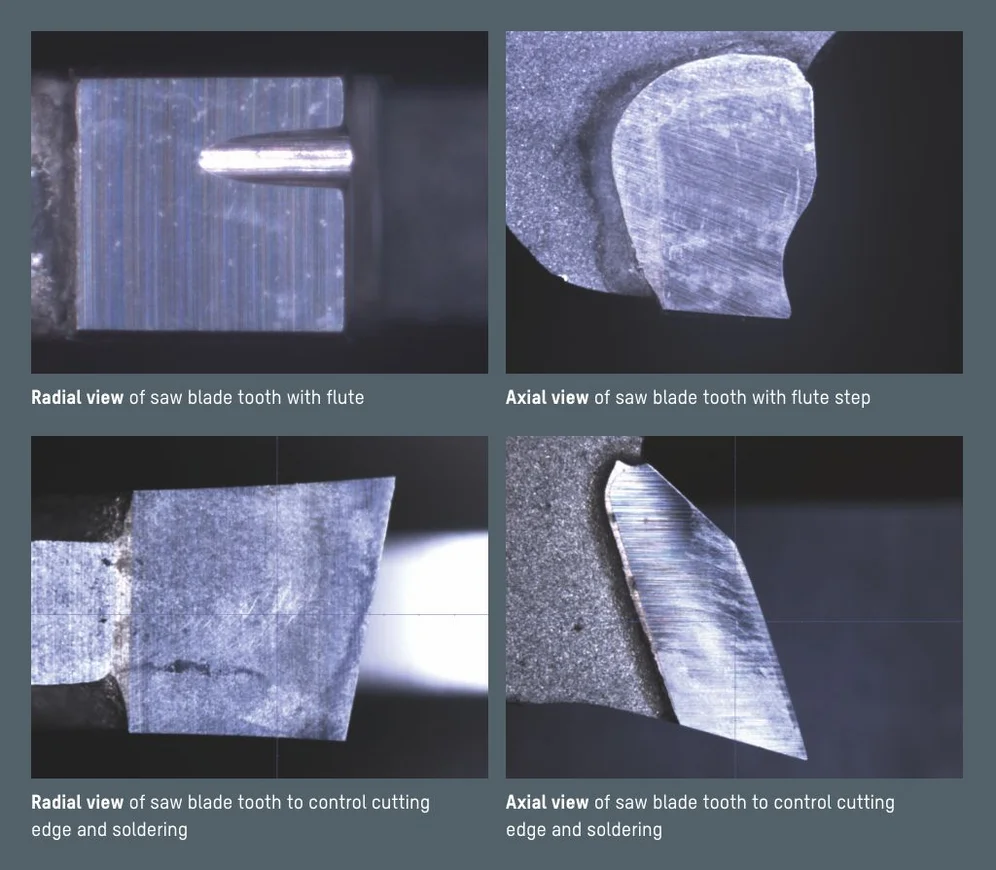

Take accurate samples right next to the grinding machine. Check the quality parameters for cutting edges and roughness with a precision of up to 0.1 µm. Have tool geometries analyzed automatically using over 100 parameters and create digital twins.

The ZOLLER Solution Inspection & Measuring proves what many claim: quality.