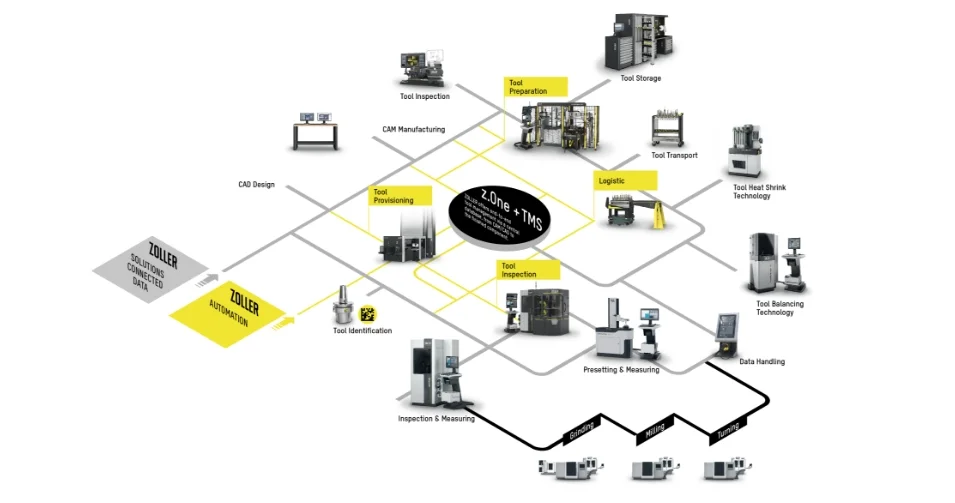

With ZOLLER's holistic tool management, you can increase the performance potential stored in your tool store. It combines four levels into one unit: Smart Cabinets - the ZOLLER tool cabinets -, the TMS Tool Management Solutions and WebTMS software solutions, numerous interfaces to third-party systems and data availability via the z.One database. Tool management from a single source - and therefore unbeatably efficient.

Tool management solves efficiency brakes. It speeds up access to tools, shortens set-up times, facilitates production planning, supports purchasing, prevents excessive capital commitment and reduces machine downtime. ZOLLER tool management can reduce costs by 10% to 40% in each of these areas. In your production too.

More success. With holistic tool management from ZOLLER.

Programmed for growth: the packages

Start your tool management at the level you currently need. ZOLLER offers you three expansion levels of the TMS Tool Management Solutions software: Bronze, Silver, Gold. When the efficiency effects become apparent and you want to take the next step, we have the perfectly coordinated upgrade.

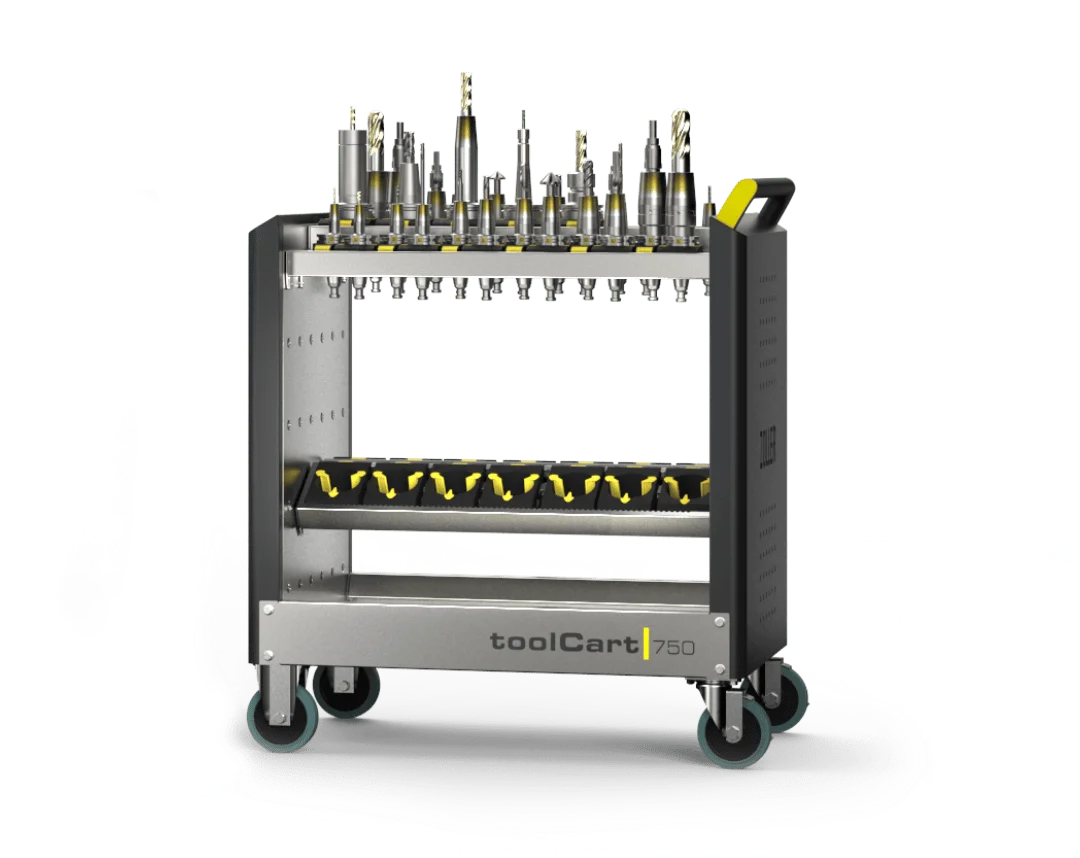

Ready for action: Smart Cabinets

Value creation begins with organization. Smart Cabinets prepare your warehouse perfectly for the next orders. Tools, tool holders, small parts, complete tools, aids and test equipment are ready to hand. The assembly stations and tool trolleys make processes such as preparation and transportation simple and ergonomic.

Programmed with practical knowledge: Database z.One

Tool management from ZOLLER provides information about tools, organizes data records and is open for data transfers and data conversions in many directions. For these processes to run, data needs a secure basis: the z.One database from ZOLLER. z.One is stored in every device and in every measuring machine and backs up all measuring data. If you prefer to manage tool data centrally - that is also possible with z.One.