We stand for smart progress

Are you searching for a powerful, universal testing and measuring machine for your cutting tools? ZOLLER offers its customers various solutions for checking tools in the most economical way before and after sharpening – unbeatable, indispensable, and 100% convincing.

With ZOLLER »smartCheck«, you can inspect and measure your tools and grinding wheels right next to the machine. You can achieve a high-precision quality check even when testing your tools before the Resharpening process.

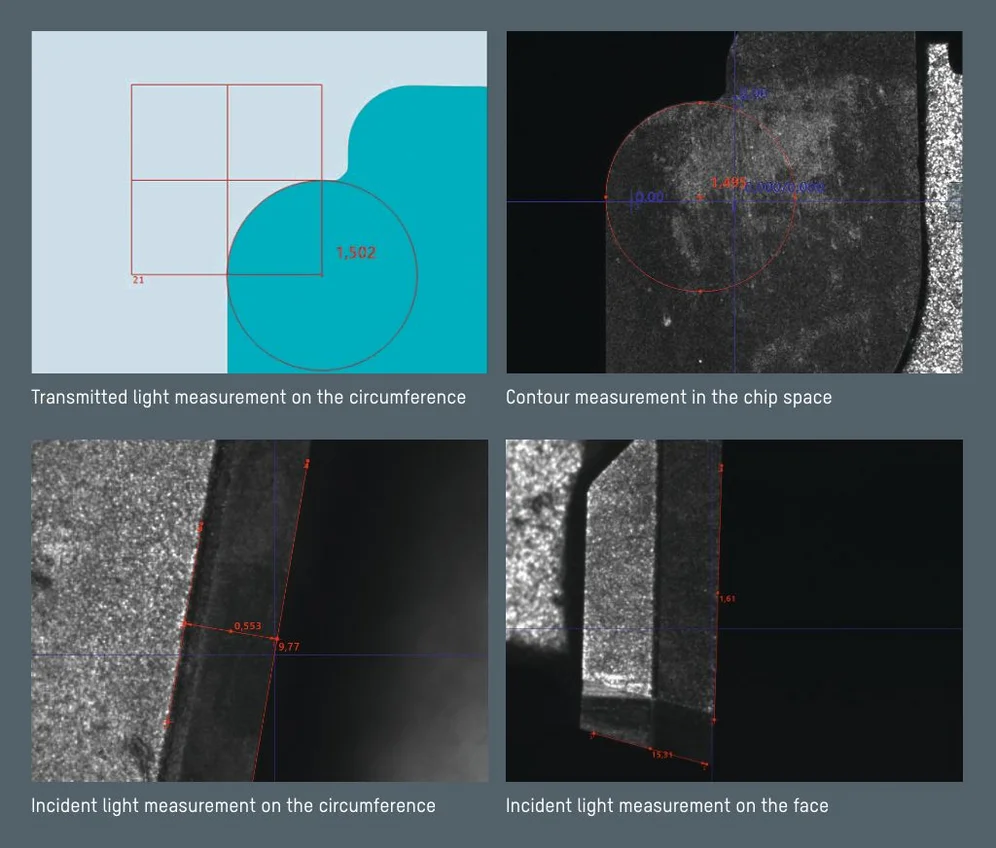

High-precision optics

The ZOLLER »smileCheck« and »smartCheck« device series with high-quality, industry-standard optics: For example, cutting edge radii, angles, lengths, diameters, etc. can be measured automatically and with μm accuracy in transmitted light on the outer contour of the tools.

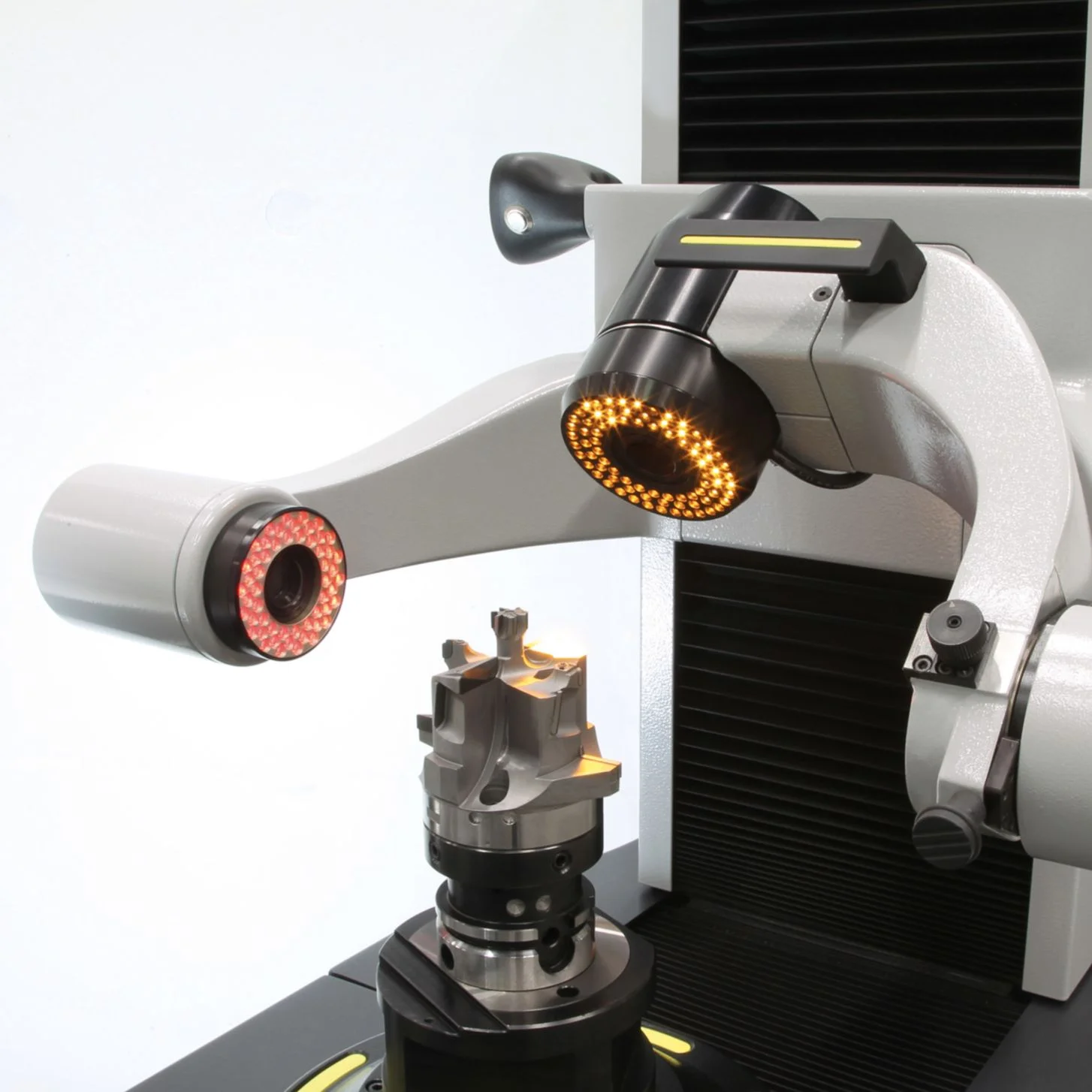

ZOLLER multisensor technology

Spindle technology »smileCheck«

Spindle technology »smartCheck«

Fact check for tools

Quality is measurable. That's why it's provable. For tool manufacturers and grinders, there is a very simple way to provide hard evidence of tool quality: testing and measuring technology from ZOLLER.

Take exact samples right next to the grinding machine. Check the quality parameters for cutting edges and roughness with a precision of up to 0.1 µm. Have tool geometries analyzed automatically using over 100 parameters and create digital twins.

The ZOLLER Solution Inspection & Measuring proves what many claim: quality.

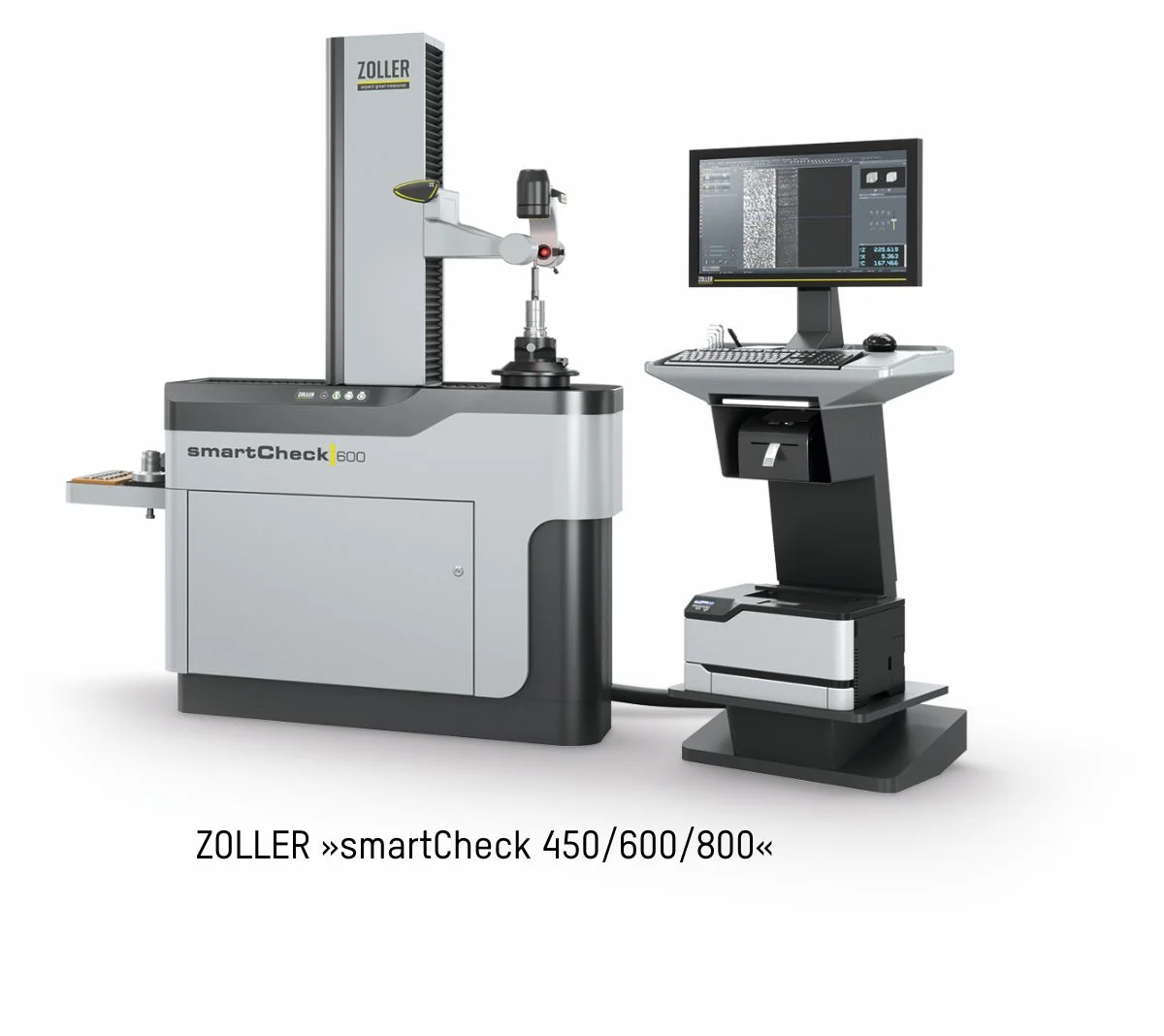

»smartCheck 450/600/800«

Process-oriented tool inspection

The »smartCheck 450/600/800« device series from ZOLLER offers you comprehensive tool inspection: State-of-the-art technologies paired with outstanding ease of use ensure efficient processes in your production. The wide range of measuring ranges and variable equipment make a »smartCheck« an all-rounder for your demanding range of tools. Rely on precise measurement data as a guarantee for the reliable quality of your products.

»smileCheck«

Precise tool quality

In addition to its convenient operating concept, ZOLLER »smileCheck« impresses primarily with its compactness and ensures reliable processes and more speed in your production. Tool parameters, geometry data and cutting contours can be recorded both radially and axially. »smileCheck« also enables you to prepare your grinding wheel packs quickly and precisely.