For endurance runs during inspection

»cockpit«

»cockpit«

You can operate »roboSet 2« conveniently and easily using the »pilot 4.0« image processing software

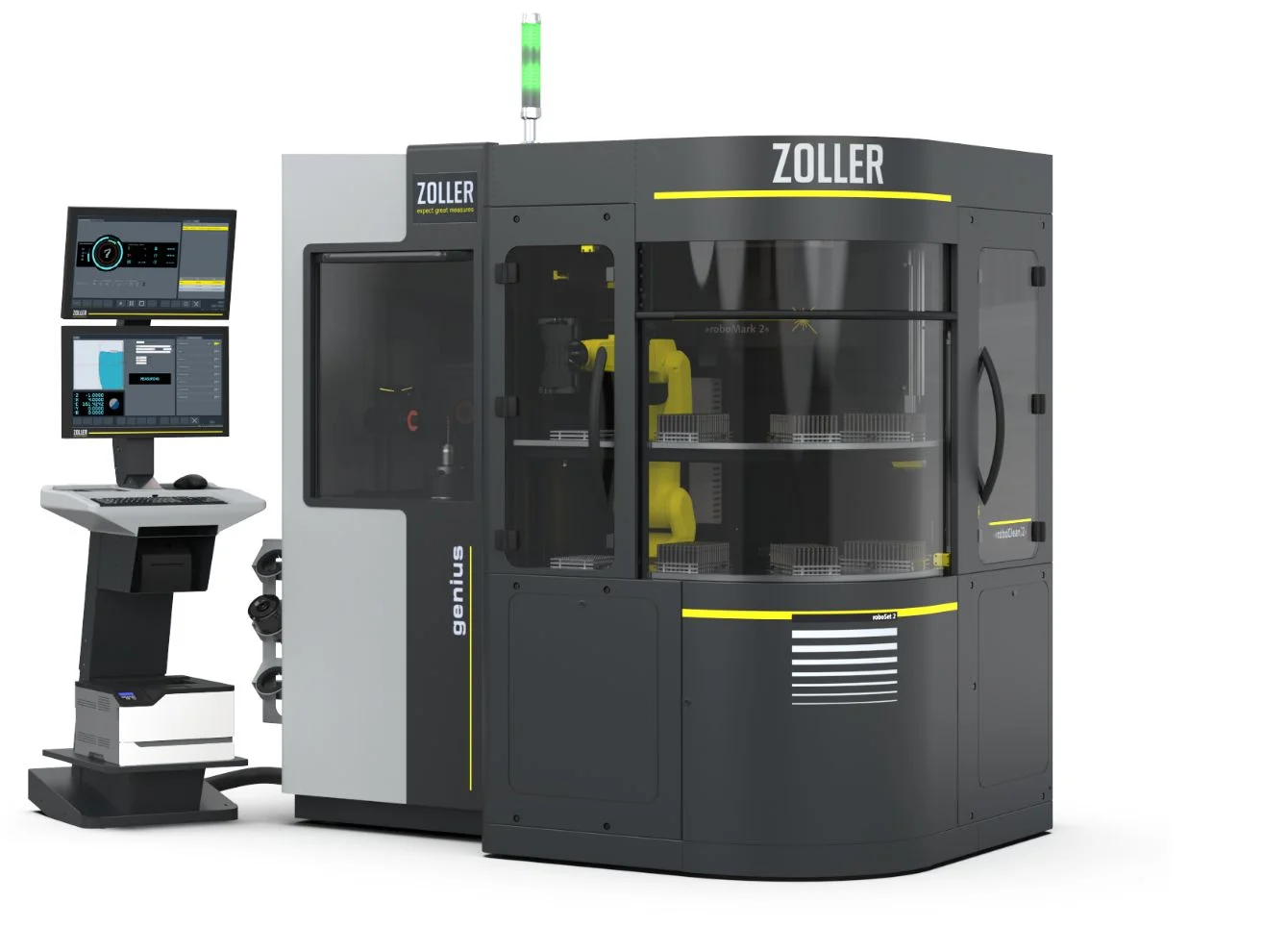

Measuring machine

Measuring machine

Can be combined with all measuring machines in the »genius« series from ZOLLER.

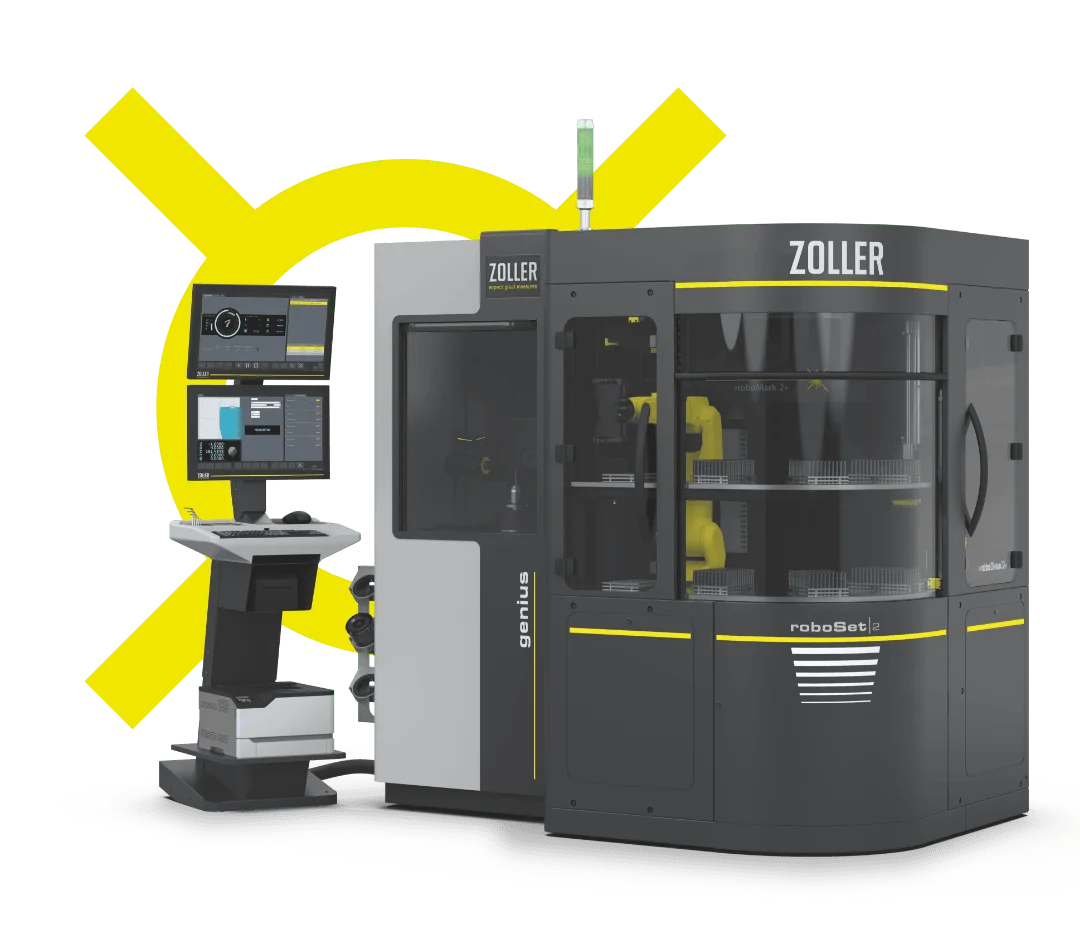

»roboSet 2«

»roboSet 2«

Loading unit with robotics, marking laser and cleaning bath. Capacity for several thousand tools.

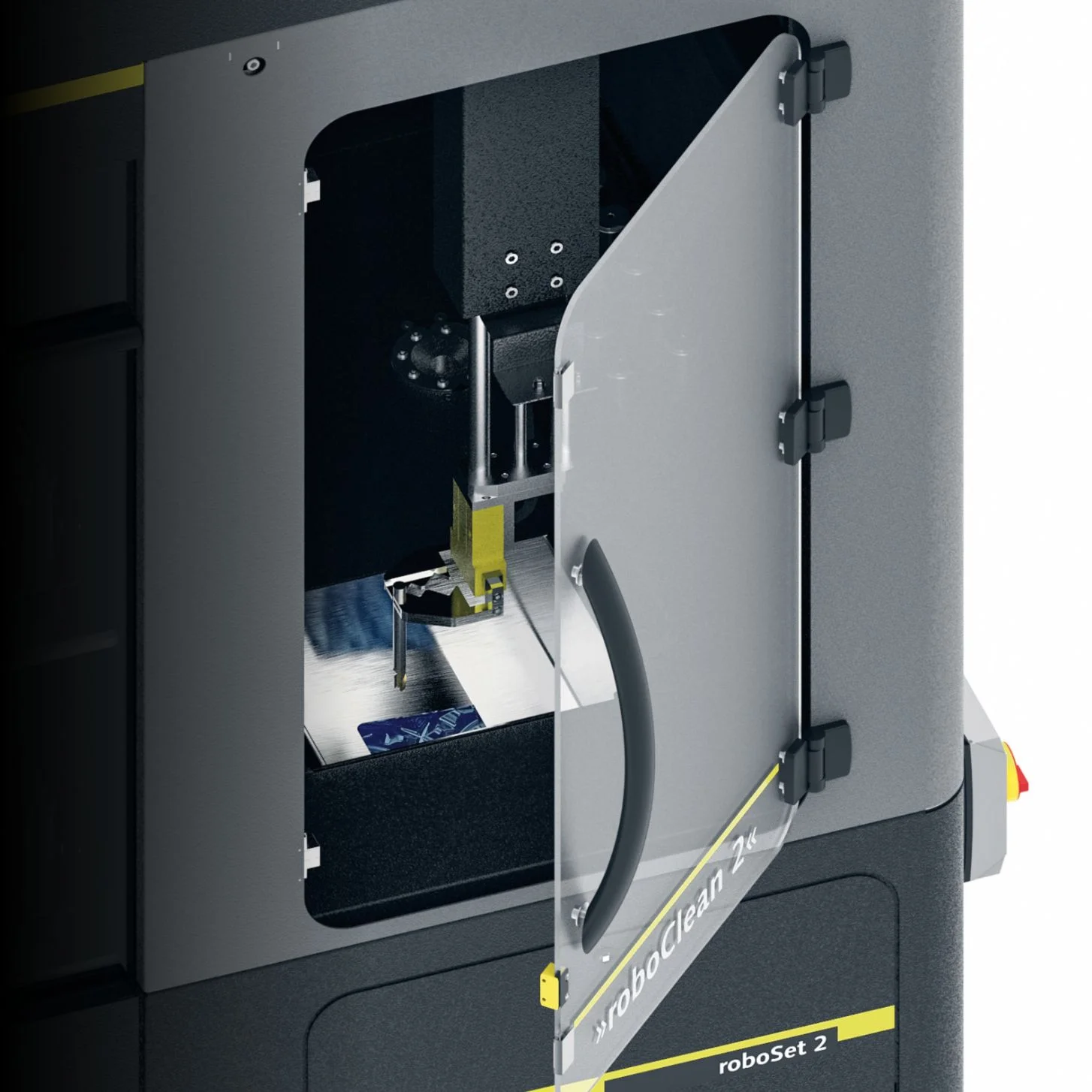

Access window

Access window

Large access window to the two pallet levels that can be easily moved upwards. High tool capacity thanks to eight pallet spaces.

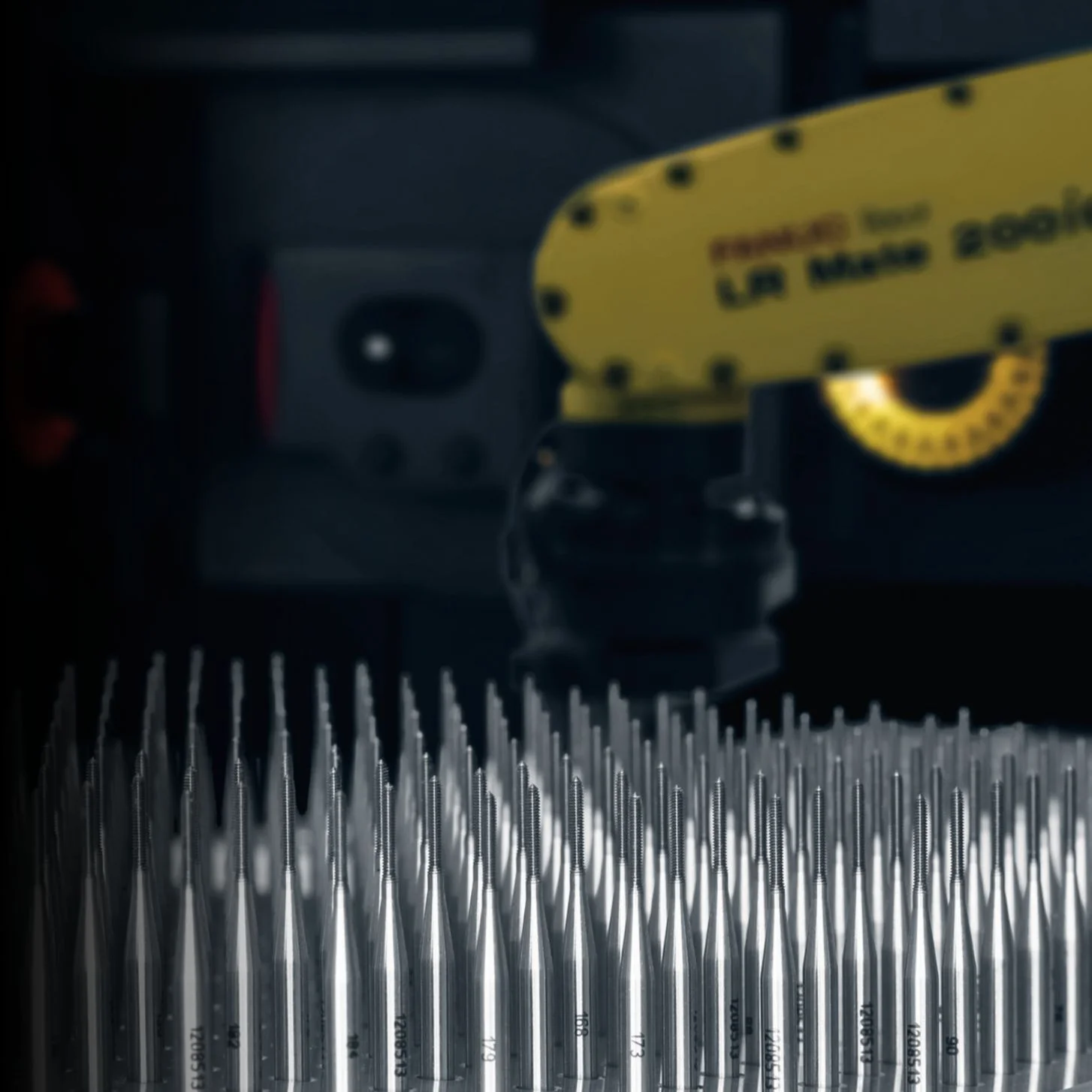

Interior

Interior

Convenient access to the ultrasonic cleaning system and the interior of the loading unit.

Freshly cleaned for testing

With ultrasonic and dry cleaning, »roboSet 2« removes microparticles, dust and organic cooling lubricants from every tool. No matter which ZOLLER measuring machine you combine »roboSet 2« with, the tools will be sparkling clean for inspection. Perfect conditions for fully utilizing the precise measuring power of ZOLLER.

Mechanically decoupled

The big robotics action is going on in »roboSet 2«. Next door, at »genius«, there is almost complete silence. To ensure that the unequal neighbors work together perfectly, »roboSet 2« was designed as a separate unit that is mechanically decoupled from the measuring machine. Vibrations and shocks do not reach the µm-precise measurement technology.

ZOLLER + GKN Aerospace: How to bring tool grinding, regrinding in-house

Case study: GKN Aerospace

Our customer GKN Aerospace has been relying on automated inspection with »roboSet 2« for two years. In the video, production expert Jeremy St. Pierre reports on his experiences with this ZOLLER solution.