We stand for smart progress

With optimally and highly precisely balanced tools, you achieve longer tool life, longer spindle life and a better surface quality of your components. With »toolBalancer«, you can achieve the perfect balance of sustainability, efficiency and progress not only for your tools, but also for your entire production process.

The high-performance interaction

»twinPanel« safety cover

»twinPanel« safety hood

Complies with DIN ISO 21940-23 class C60 for maximum safety.

The internal "sacrificial disk" absorbs dirt caused by e.g. The internal "victim disk" absorbs dirt, e.g. residues of cooling lubricants and damage caused by component detachment. This takes into account the very important and often overlooked process of protective disk switching that occurs through daily use. The ZOLLER »twinPanel« guarantees the safety of your operators in the long term thanks to the quick and cost-effective replacement of the sacrificial screen.

High-precision spindle

High-precision spindle

Accepts almost any tool holder with an appropriate balancing adapter. Depending on the weight, the spindle rotates the tool at a variably adjustable speed of 400 to max. 1200 revolutions per minute and measures the unbalance with an accuracy of < 0.4 gmm.

When designing the high-precision spindle, ZOLLER placed a particular focus on the safe and certified adapter changing process. A special design element prevents accidents and damage caused by unbolted balancing adapters in the spindle.

Adapter storage compartment

Adapter storage compartment with hinged front flap

Three storage spaces for ergonomic, back-friendly and quick adapter changes without bending your knees.

Fork recess

Fork recess

For flexible installation and easy transportation of the »toolBalancer« in your production facility using a pallet truck.

ZOLLER operating software

Simple ZOLLER operating software

The structured, graphical display guides the operator intuitively through the measuring and balancing process.

The machine is set up by entering the tool geometry data. All data is stored in the database and is also available at a later date.

»Cockpit« control unit

Separate »cockpit« control unit

Can be adjusted in height and position and the monitor can be tilted. It can be easily moved to the desired position, making operating the software as convenient as possible.

In addition to touch operation, the »cockpit« offers input options via mouse and keyboard, as well as shelves for label and laser printers, hand scanners and tools such as Allen keys.

Reach your destination with safety and speed

»toolBalancer« makes tool balancing especially simple: thanks to the ergonomically designed »twinPanel« safety cover, convenient membrane keypad, compartment for balance adapters, and compartments in the large work area.

The ZOLLER operating software with its structured graphic representation intuitively guides the operator through the measuring and balancing process. Using the appropriate software options, all balancing applications are available on 1 to 2 balancing levels, such as fixed position compensation with balancing screws or the use of balancing rings or balancing by material removal such as drilling or milling.

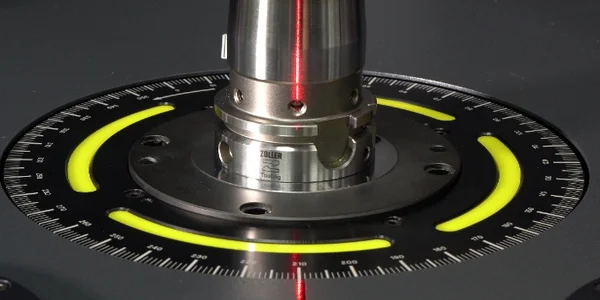

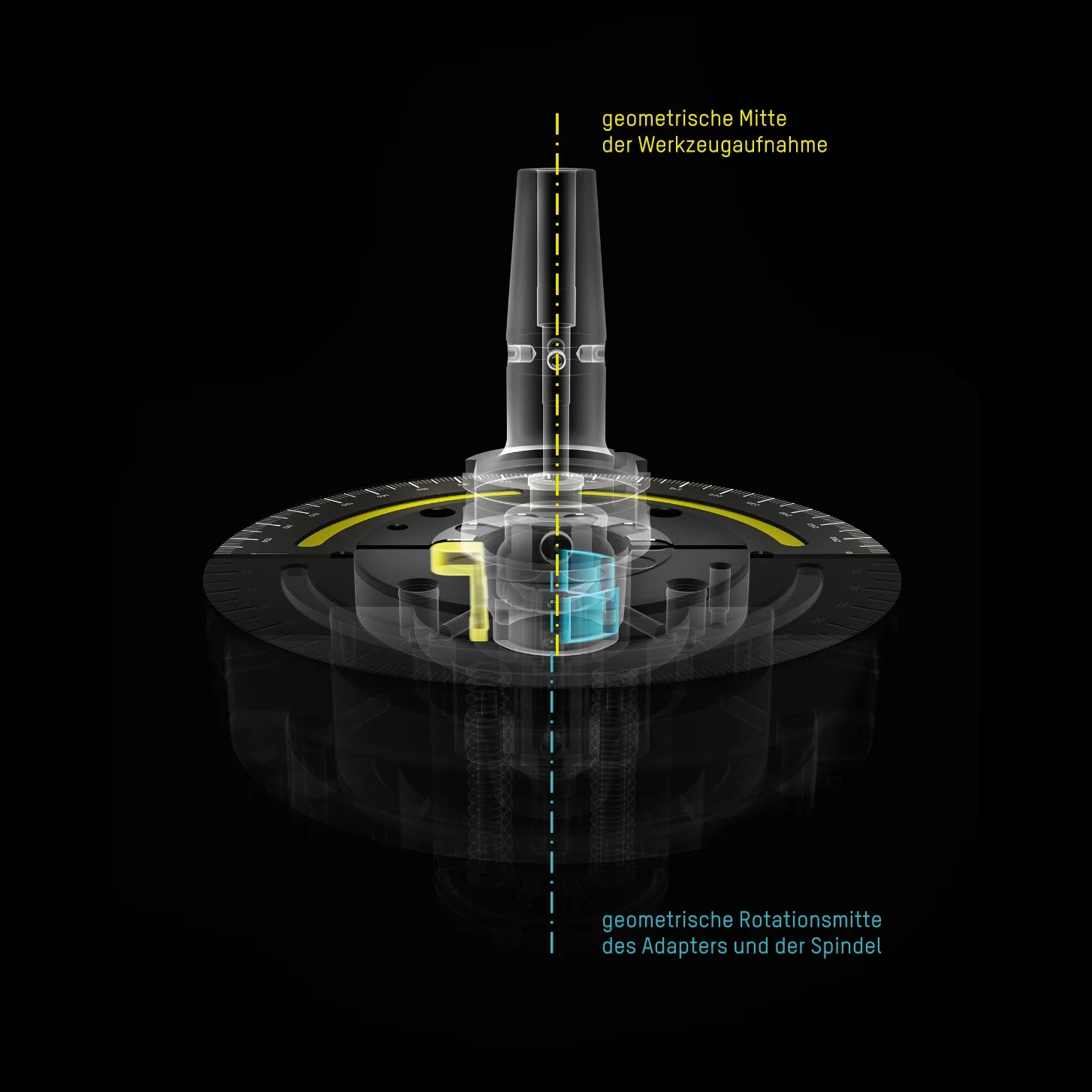

From the center to the highest precision

An unbalance on tools is caused by an asymmetrical design and the associated asymmetrical mass distribution. The ZOLLER »toolBalancer« solves this problem by using a deliberate center offset in the balancing adapter when measuring and balancing your tools.

The balancing adapter with center offset is designed with a two-point system and a thrust piece. This results in a large and more measurable sensor signal and guarantees high-precision balancing results, especially with high balancing quality and low unbalance.

Balancing means peace of mind for tools

Vibrations occur when rotating tools do not run smoothly. Even at low speeds, this can lead to increased tool wear, loss of surface quality and additional stress on the machine spindles. Therefore, have your tools regularly checked on a balancing device from ZOLLER.

Find out more about the advantages of ZOLLER Solution balancing.

More about balancing technology