At ZOLLER, the willingness to innovate is the most important ingredient for continuous progress.

We have been creating the future for 75 years.

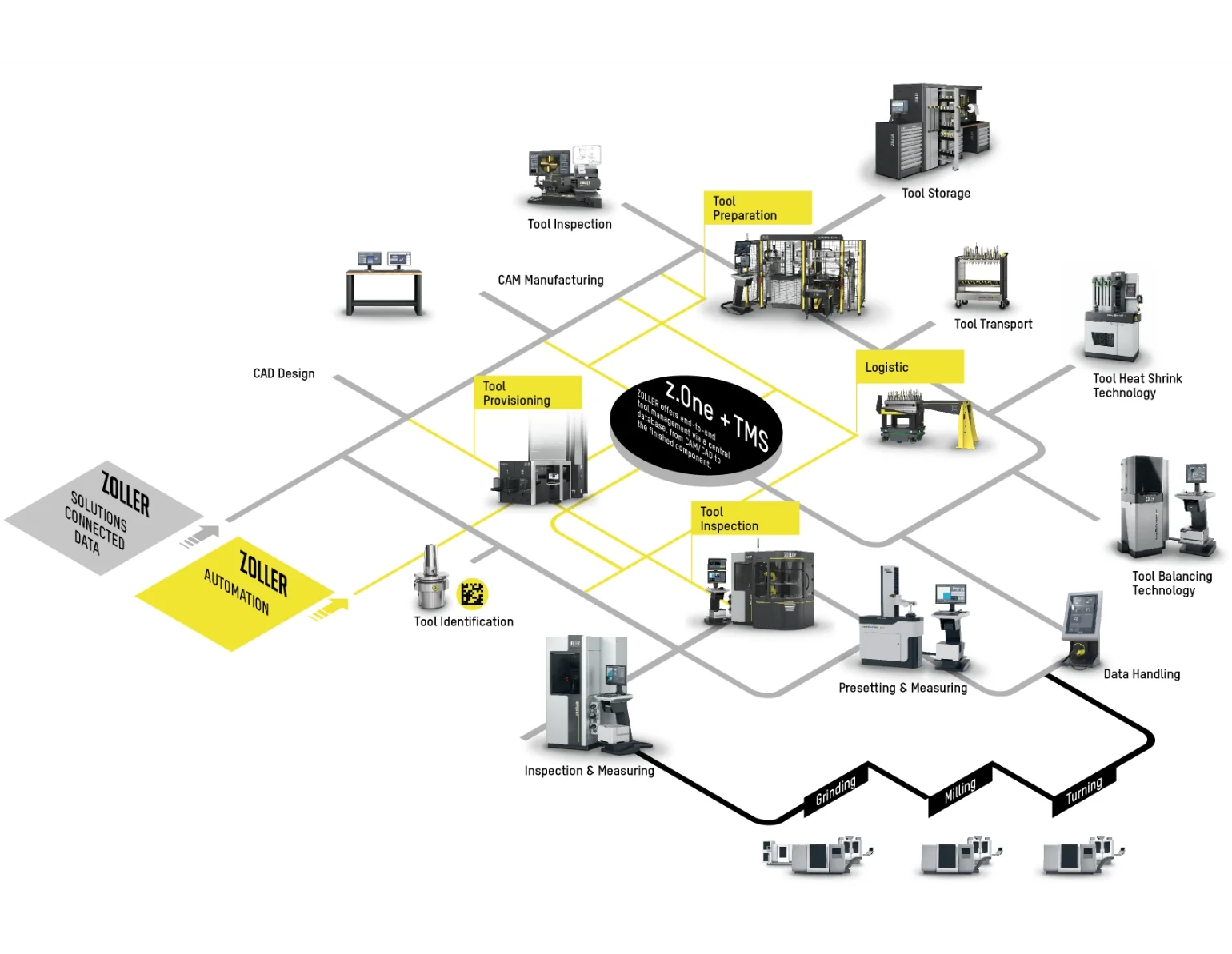

Start with a Solution - Enter a System.

The safest way to remain operational in the long term is to opt for an integrated system.

ZOLLER is the only manufacturer in the world that can offer you such a system. It focuses on cutting tools and uses data to network the associated processes. The result: maximum efficiency, quality and precision for your machining production.

You start where you are. You stop where your requirements are met. And you always have the certainty of being able to take the next step.

Tool Management

Tool cabinets, assembly stations, software, and interfaces: ZOLLER creates order in the tool room and improves the transparency of tool data.

Tool Heat Shrink Technology

The most innovative solutions for shrinking and unshrinking tools: First-class user guidance, reduced energy consumption, and record-breaking short process times.

Tool Balancing Technology

Longer tool life, higher surface quality: with the best balancing equipment on the market.

Tool Holders with ZOLLER »idChip«

»idChip« – the perfect interface between tools and digital manufacturing.

Grinding

For tool manufacturers and grinding companies, measurement data and data management are essential for achieving high efficiency and documented quality. ZOLLER has everything you need to do this.

Milling

Greater cost-effectiveness for milling processes thanks to µm-precise tool data and digitization from CAM to part.

Turning

Precise adjustment and measurement of turning tools and high data availability: Increase the productivity of turning applications now.

»zidCode«

Greater safety and efficiency through automated, error-free tool data handling.

Presetting & Measuring

This reduces setup times by 40% or more and increases the service life of your tools.

Process-oriented measurement

Quickly and accurately check tools upon receipt of goods or check grinding quality right next to the machine—the process-oriented solutions from ZOLLER.

Tool Preparation

Automate tool setting and measurement, including tool handling. Even common process chains run independently with ZOLLER.

Tool Provisioning

With ZOLLER, you can have all tools for the next production orders provided automatically.

Tool Inspection

How to automate tool inspection with the »genius« series measuring machines. Optionally available with laser marking and complete documentation.

Tool Logistic

Your tools are automatically transferred from the tool preparation area to the CNC machine – or to the tool magazine. And back again.

CAD Design

ZOLLER's tool management provides tool data from the start of the process to the end. Our interfaces transfer tool data from CAD/CAM systems, ERP systems, and tool catalogs to the ZOLLER TMS Tool Management Solutions software.

CAM Manufacturing

Tool management with ZOLLER ensures that your data is consistently available from CAM to part with the z.One database. This simplifies production planning, reduces setup times, and minimizes missing parts—from the start of the process with CAM and CAD to the control of CNC grinding or production machines.

Tool cabinets, assembly stations, software, and interfaces: ZOLLER creates order in the tool room and improves the transparency of tool data.

The most innovative solutions for shrinking and unshrinking tools: First-class user guidance, reduced energy consumption, and record-breaking short process times.

Longer tool life, higher surface quality: with the best balancing equipment on the market.

»idChip« – the perfect interface between tools and digital manufacturing.

Document quality and create digital twins.

For tool manufacturers and grinding companies, measurement data and data management are essential for achieving high efficiency and documented quality. ZOLLER has everything you need to do this.

Greater cost-effectiveness for milling processes thanks to µm-precise tool data and digitization from CAM to part.

Precise adjustment and measurement of turning tools and high data availability: Increase the productivity of turning applications now.

Greater safety and efficiency through automated, error-free tool data handling.

This reduces setup times by 40% or more and increases the service life of your tools.

Quickly and accurately check tools upon receipt of goods or check grinding quality right next to the machine—the process-oriented solutions from ZOLLER.

Automate tool setting and measurement, including tool handling. Even common process chains run independently with ZOLLER.

With ZOLLER, you can have all tools for the next production orders provided automatically.

How to automate tool inspection with the »genius« series measuring machines. Optionally available with laser marking and complete documentation.

Your tools are automatically transferred from the tool preparation area to the CNC machine – or to the tool magazine. And back again.

For convenient tool transport

ZOLLER's tool management provides tool data from the start of the process to the end. Our interfaces transfer tool data from CAD/CAM systems, ERP systems, and tool catalogs to the ZOLLER TMS Tool Management Solutions software.

Tool management with ZOLLER ensures that your data is consistently available from CAM to part with the z.One database. This simplifies production planning, reduces setup times, and minimizes missing parts—from the start of the process with CAM and CAD to the control of CNC grinding or production machines.

The value system for modern manufacturing

ZOLLER's system-oriented solution approach is based on four core values: Innovation, quality, precision and service. We adhere to these values with every product that we develop, manufacture and deliver. Our customers are satisfied. Because our values ensure performance.

At ZOLLER, experts assemble every appliance by hand. And their name stands for the result: reliability made in Germany.

ZOLLER uses the finest measurement technology. Our top devices resolve structures below 1 µm and provide precise data that answers many questions.

Reliability is what counts at ZOLLER. You can reach us in 62 countries around the world. From Argentina to Vietnam, we are there for you!

Balancing tools at the highest level

»toolBalancer« from ZOLLER is state of the art worldwide when it comes to balancing tools. They achieve balancing results < 0.4 gmm with high ergonomics and simple operation. All »toolBalancers« are TÜV and UL/CSA approved.

Appear large when shrinking

»powerShrink« shrinks tools record-breakingly quickly and uses energy extremely sparingly. Shrink fit chucks are gently heated and cooled - high efficiency for your shrinking processes.