We stand for smart solutions

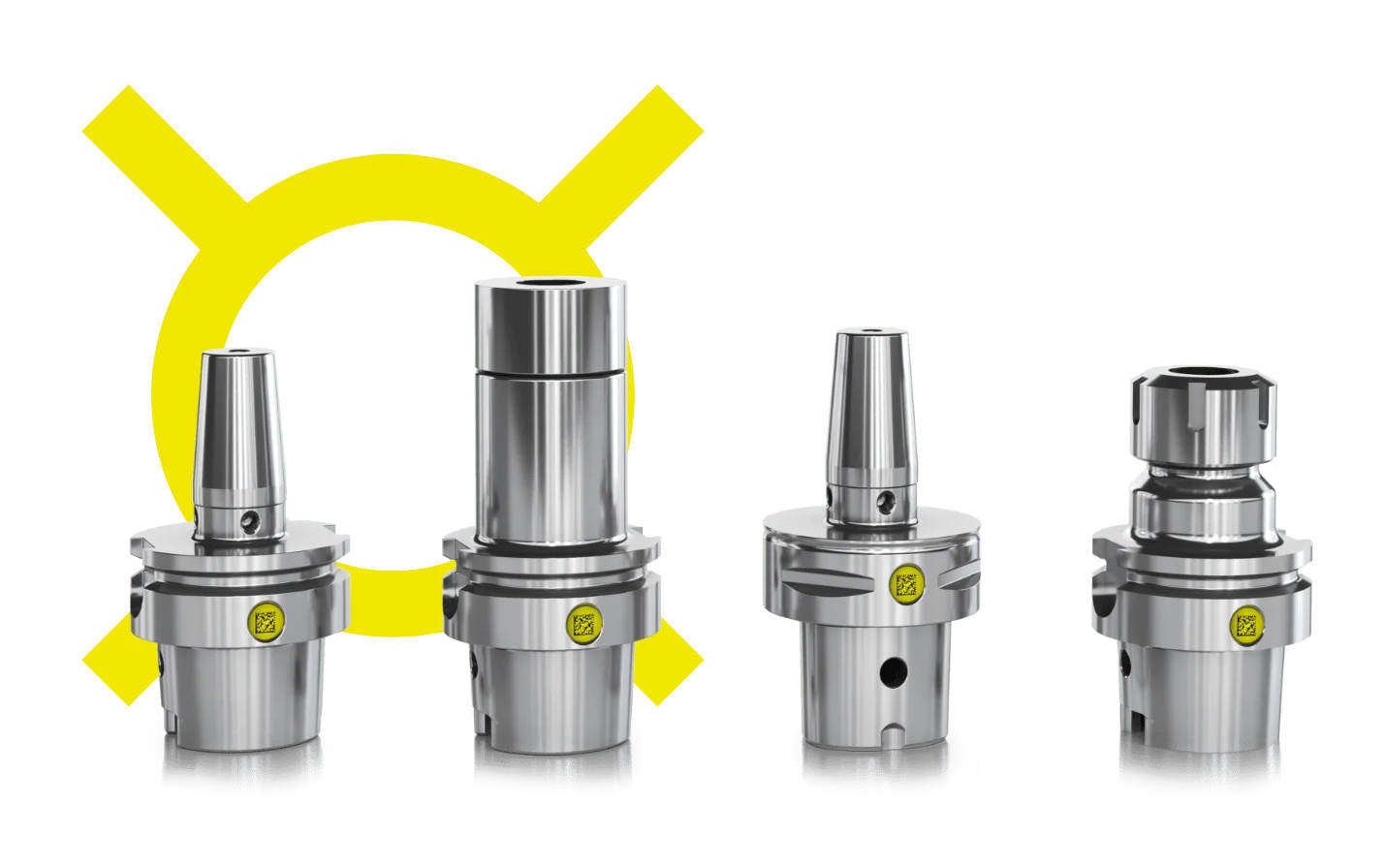

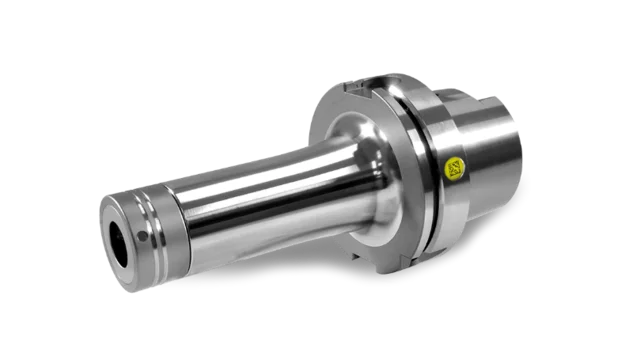

Tool holders with ZOLLER »idChip«. At your request, we can supply all tool holders with an integrated chip and DataMatrix code. You can clearly identify your tool holders at any time and simply know everything: number of heating processes, inserts on the machine and much more. The processing of the important functional surfaces on the tool holder, such as the hard-machined clamping shoulders and driver grooves, guarantees a long service life and maximum precision in the machining process. Sustainable, economical: this is the future.

Reliability for maximum precision

Chip drilling

Chip hole

For attaching data carriers such as RFID chips or ZOLLER »idChip« to the ZOLLER Tooling tool holders. Standard for hollow shank tapers HSK-A, steep tapers SK and polygonal shank tapers PSC.

ZOLLER »idChip«

For unique identification of your tool holders and for maximum product service life. At your request, we can also supply balanced tool holders with a permanently integrated chip directly to your production facility.

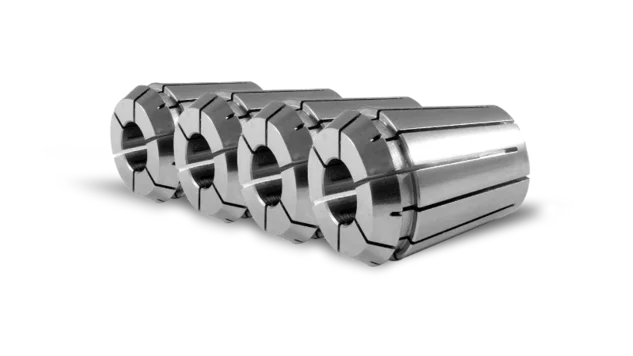

3-groove technology

In the chip bore of the tool holder, the adhesive guarantees a positive fit for a secure and firm connection.

Four threads

Four threads

For subsequent fine balancing of standard shrink fit chucks.

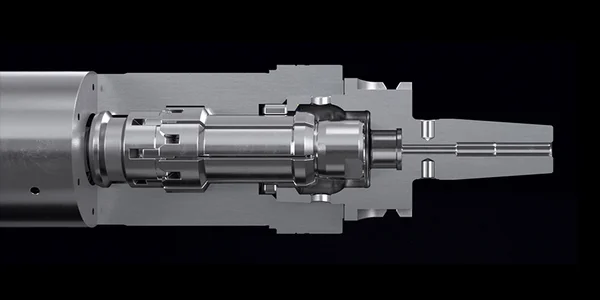

Long shrink fit

Long shrink fit with insertion radius

Guarantees maximum shrinking forces thanks to the tension of the tool along the entire length of the shaft.

Pull-in shoulder

Hard reworked feed shoulder

Guarantees optimum sliding of the clamping segments on the clamping shoulder and excellent clamping in the spindle. This results in concentricity at the clamping shoulder of maximum 10 μm (5x more accurate than DIN).

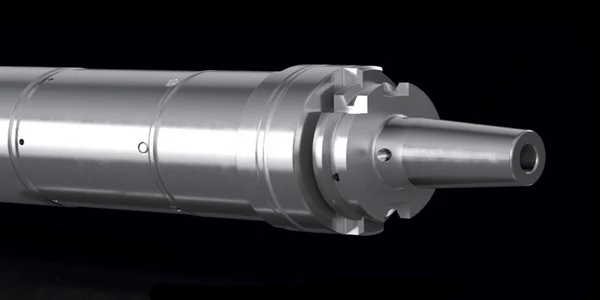

Concentricity tolerances

Concentricity tolerances

Tooling Solutions guarantee concentricity < 3 µm.

Finely balanced

Finely balanced

All ZOLLER Tooling tool holders are precision-balanced - G2.5 at 25,000 min-1 or max. residual imbalance ≤ 1 gmm. This results in smooth, bearing-friendly spindle running during machining. You benefit from a longer spindle service life, an optimum workpiece surface and longer tool life.

Driving grooves

Hard reworked driver grooves

Guarantee a 100 % center position of the keyways, a perfect fit in the spindle and excellent torque transmission.

Ejection surface

Hard reworked ejection surface

Guarantees safe release of the HSK tool holder when changing tools.

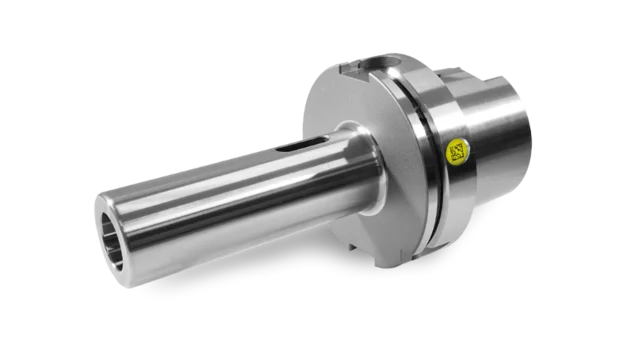

»coolTool«

»coolTool«

For a perfectly cooled tool cutting edge, optimum chip guidance and the prevention of chip accumulation on the tool cutting edge. The angled positioning of the coolant holes guarantees that your coolant reaches where it is needed: your tool cutting edge. This enables you to achieve optimum cutting results and increase the service life of your tools.

ZOLLER Tooling Solutions – Tooling Heroes

Typical ZOLLER - everything from a single source

When developing new products, ZOLLER always goes one step further and creates solutions for the future. We have been pursuing this principle for decades, and not just with our measuring machines. Equip yourself for the digital requirements of tomorrow and prepare for the smart factory of the future - with our ZOLLER Tooling Solutions.

ZOLLER Tooling Solutions – The Perfect Interface for Your Digital Manufacturing

ZOLLER Solutions for your efficient production

Benefit from our ZOLLER Tooling Solutions for your effective manufacturing process. We offer you a complete range of high-performance and high-precision tool holding systems for your machining tasks. ZOLLER Tooling Solutions also form the perfect interface for your digital production.