»actbyLight«

We stand for smart progress

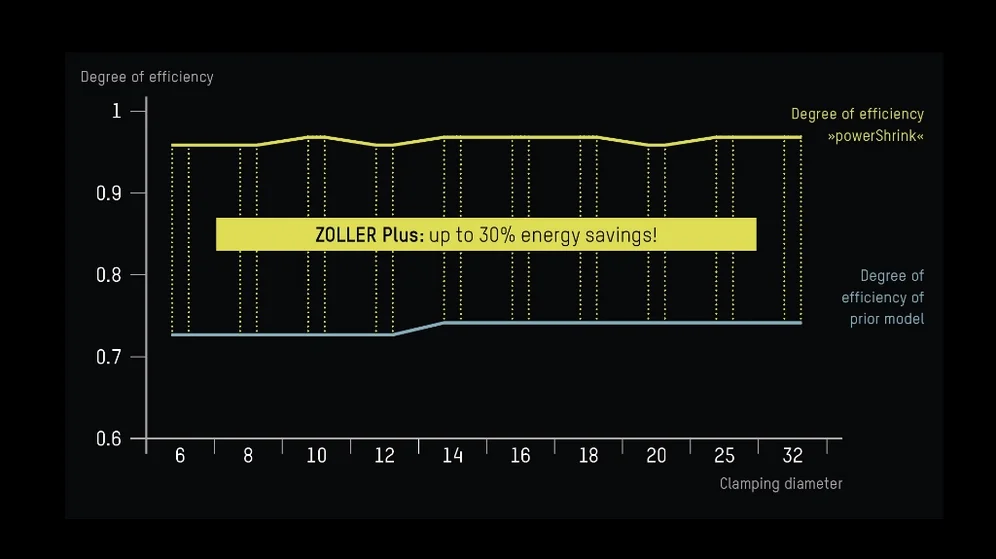

Shrink and unshrink tools in record time while saving energy and protecting liners: you get all these advantages with the »powerShrink« inductive shrink system. The »powerShrink« device series allows you to increase the efficiency of your production.

»actbyLight« guides you safely through the shrinking process and includes the »shrinkbyLight« coil function, LED control on the induction coil, and »coolbyLight« LED user guidance on the cooling system.

ZOLLER Re-inventing the induction coil

Shrink technology

Smart design for maximum efficiency

The ZOLLER induction coil is an intelligent, well thought-out highlight of the »powerShrink«. Two windings connected in parallel within the coil can be activated separately and controlled differently depending on the clamping diameter and length. This enables optimum energy input into the clamping area, accelerates the heating and cooling process and protects your tool holders.

Coil with »varOct« shielding system Coil with shielding discs

»coolbyLight«

Cool highlights for efficient cooling

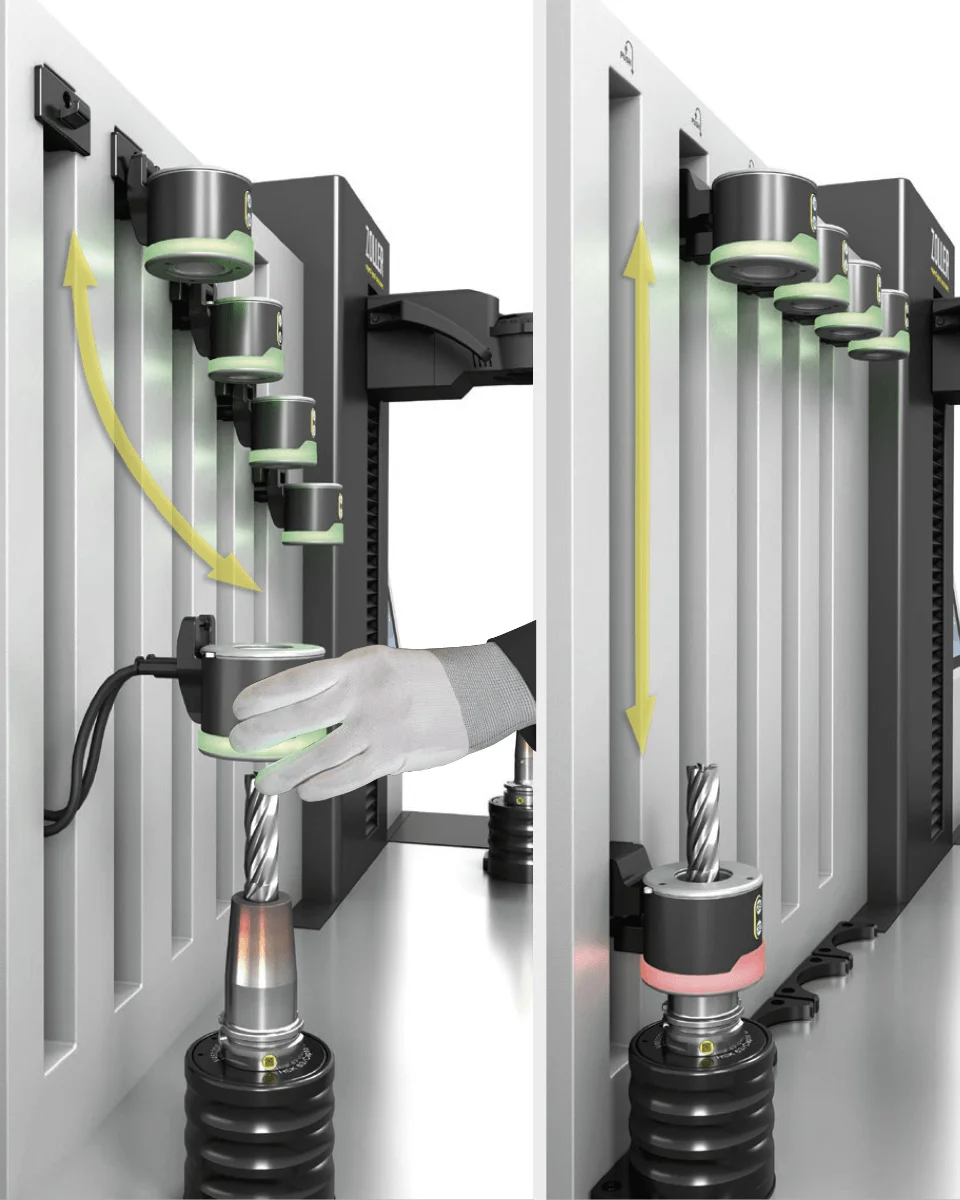

With »powerShrink« from ZOLLER, you can cool with maximum efficiency. The five cooling bells for standard-compliant shrink fit chucks from D6 mm to D32 mm ensure fast, even cooling thanks to their intelligent design and integrated contact cooling. Your shrink fit chucks are protected and the high concentricity is maintained.

The high-performance interaction

»coolbyLight«

»coolbyLight« operator guidance

Innovative cooling bells with »coolbyLight« operator guidance, cooling management and diameter display - guide the operator safely through the cooling process with the help of the color system and the LEDs on the cooling bells. The cooling bells are also marked with the corresponding tool diameters.

The »powerShrink 600« is also optionally available with standard cooling bells or with »zStream« air cooling.

Coil axis

Smooth-running bobbin axle

Smooth-running bobbin axle - for fast and comfortable movement of the bobbin. The pneumatic release of the axle clamp, the high-precision THK linear guide and the counterweight allow the operator ergonomic work processes and a long service life. The maximum tool length is 600 mm.

Induction coil

Induction coil with »varOct« shielding system

Intelligent induction coil with »varOct« shielding system - with ergonomic handles on the left and right side, incl. membrane function buttons for moving the coil and activating the heating process. Thanks to the maximum internal diameter of 45.8 mm, tools with larger cutting diameters can also be easily shrunk in and out. The inner diameter of the »varOct« can be quickly and easily set to the desired diameter manually or automatically as an option using a raster.

Alongside »coolbyLight«, ZOLLER »shrinkbyLight« is one of the two functions of the ZOLLER »actbyLight« operating concept. This optionally available operator guidance system for the coil uses LEDs to indicate which windings are active and whether the selected diameter matches the selected data set. An incorrectly set coil is therefore impossible! The fume extraction system protects the operator.

TFT touch monitor

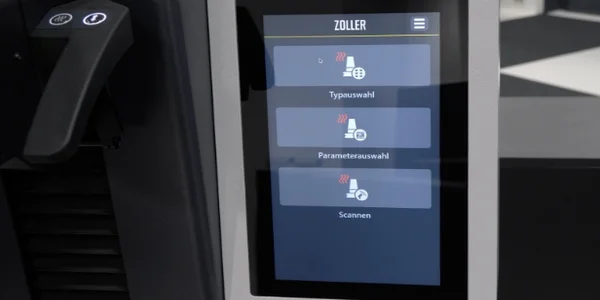

TFT touch monitor with ZOLLER »pilot« software

Industrial-grade 12.5-inch TFT touch monitor with ZOLLER »pilot« software - impresses with a razor-sharp display and simple touch operation. The clearly structured graphical software interface guides you intuitively through the shrinking process using large function areas and colors. The intelligent cooling system, the cooling manager, coordinates the cooling times depending on the chuck diameter and switches off the cooling module after a defined time. This also saves energy.

Under table

Sturdy under-table

Stable undercounter - forms the perfect basis for a long-lasting product thanks to its particularly robust design. The front door can be opened and the water cooler, which is mounted on a drawer, can be pulled out for maintenance and inspection.

Storage shelves

Ergonomic storage shelves

Ergonomic storage shelves on the left and right - provide space for positioning hand scanners, cleaning brushes, safety gloves, cooling adapters and pick-up rings close to the process, thus rounding off the ergonomic operation of the appliance.

Storage space

Large storage space

Large storage space - for cooling components, fume extraction and for storing your accessories such as the shrink fit unit.

All components are organized and neatly stored in three compartments integrated in the lower table, including a pull-out drawer

Work surface

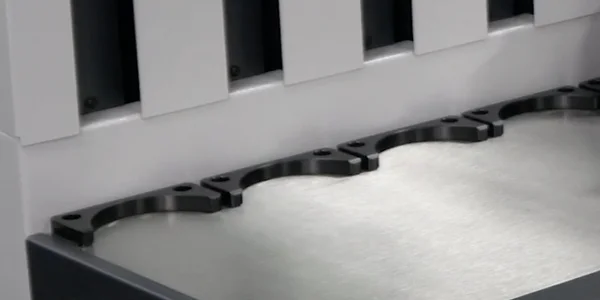

Robust and smooth work surface

Robust and smooth work surface - made of stainless steel offers sufficient space for heating and cooling your shrink fit chucks.

The material is optimally matched to the mounting pots so that the tool can be moved easily, quietly and quickly.

Cooling bell guide

Cooling bell guide

Smooth-running, linear, mechanical cooling bell guide - allows the cooling bells to be positioned precisely and securely on your shrink chucks. When the cooling bell is released via the push-to-release mechanism, a counterweight ensures that it does not fall down abruptly. This is safe and protects against injuries. The guide also ensures that the cooling bell does not touch the cutting edge when it is put on and therefore cannot damage it.

Optionally also available with a simple fixing mechanism.

Hand scanner

Practical hand scanner

Practical hand scanner - for a quick and reliable start to your shrinking process. Simply scan the DataMatrix code on the ZOLLER »idChip« and all the necessary shrink parameters are immediately available in the »pilot« software.

ZOLLER has fundamentally modernized shrinking

A new era has begun in shrink technology. We have not only redeveloped the key elements of shrink units. We have brought a generation of devices onto the market that is far superior to all other solutions.

High savings in energy consumption, heating with almost 100% efficiency, extremely fast cooling and clever user guidance - shrinking and unshrinking with ZOLLER redefines an established process.

Convince yourself now of the ZOLLER Shrinking Solution.

More about shrinking technology