Customer success with ZOLLER

Higher profits, more orders, less time required, lower production costs - ZOLLER increases the efficiency of its customers worldwide.

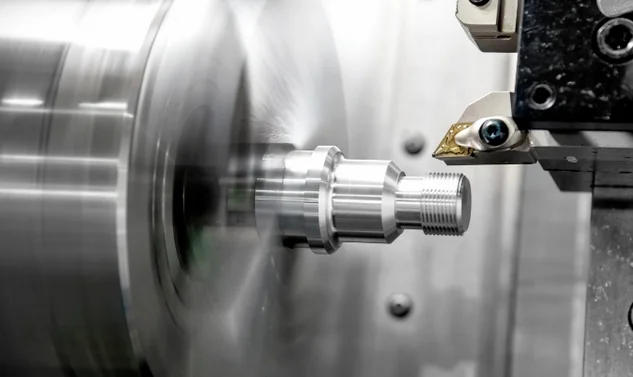

This is how much a ZOLLER »hyperion« reduces set-up times at SycoTec. Turning tools and multiple turning holders are measured on the horizontal setting and measuring machine. Then they produce high-speed micromotors.

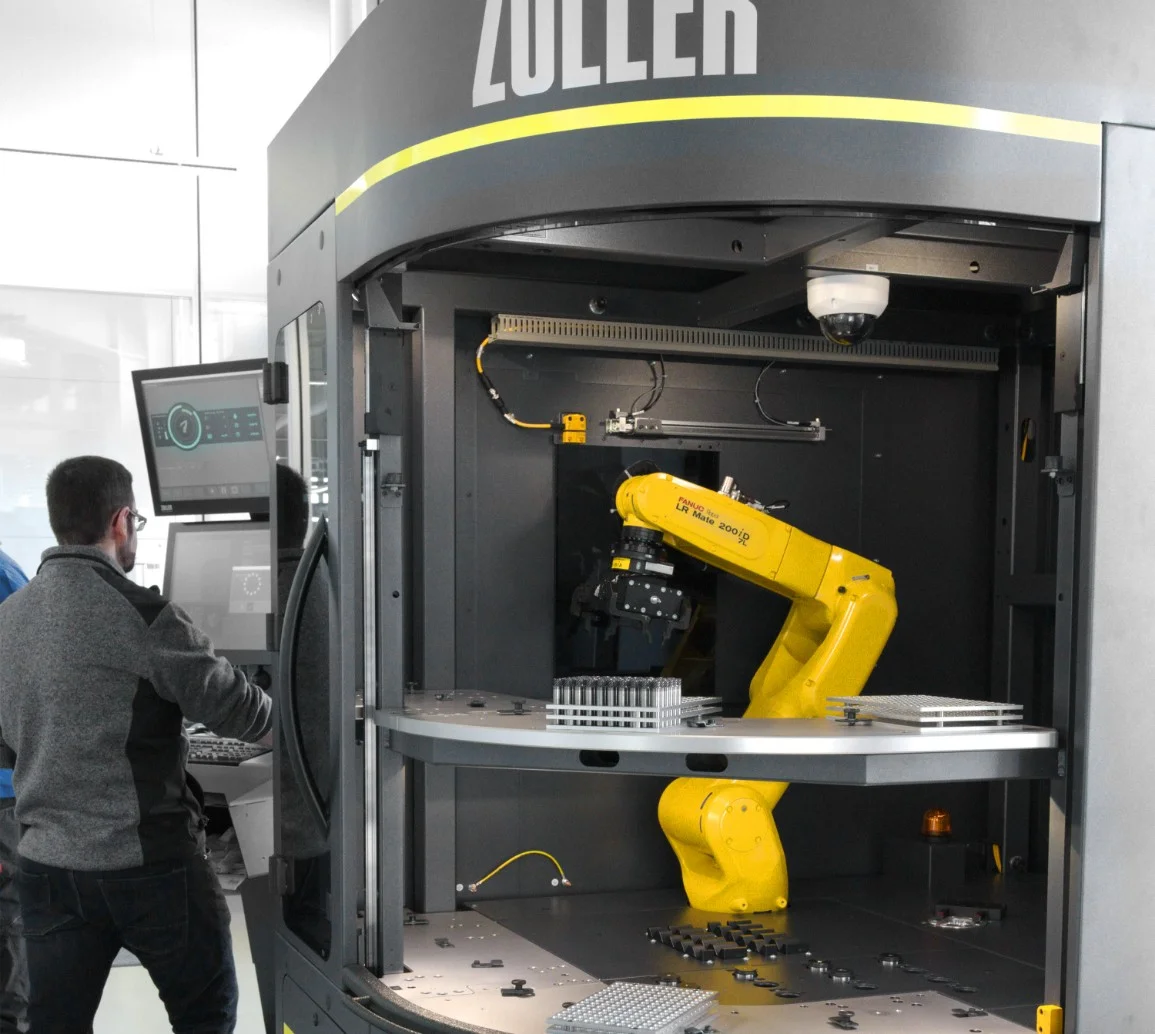

This is the potential reduction in personnel costs when inspecting tools in three-shift operation if you use the »roboSet 2« automation solution.

This is the average time it takes for a »smile« presetting and measuring machine to pay for itself. Basis: Production in single-shift operation with one CNC machine. With two machines, the time is halved.

The family business ProCam from Michigan/USA has increased its turnover by USD 1 million within two years of purchasing a »smile 420«. Thanks to shorter set-up times and less machine downtime, ProCam was able to process more orders.

Balancing tools at the highest level

»toolBalancer« from ZOLLER is state of the art worldwide when it comes to balancing tools. They achieve balancing results < 0.4 gmm with high ergonomics and simple operation. All »toolBalancers« are TÜV and UL/CSA approved.

Appear large when shrinking

»powerShrink« shrinks tools record-breakingly quickly and uses energy extremely sparingly. Shrink fit chucks are gently heated and cooled - high efficiency for your shrinking processes.