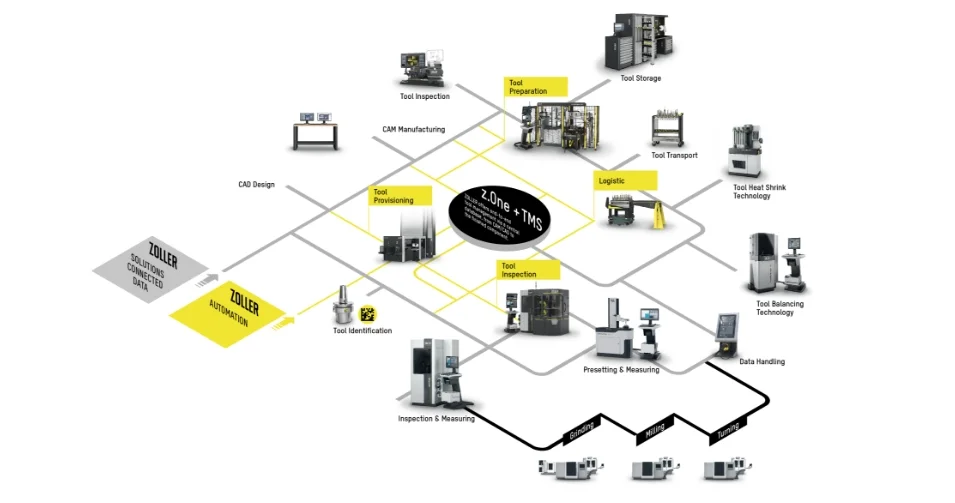

Your potential for more productivity from CNC grinding machines*

25 %

* Practical experience: High time savings in grinding and regrinding processes thanks to precise measurement data and optimally calibrated grinding wheels; shorter set-up times thanks to automated data transfer.