»actbyLight«

In the end, only one thing counts - outstanding quality

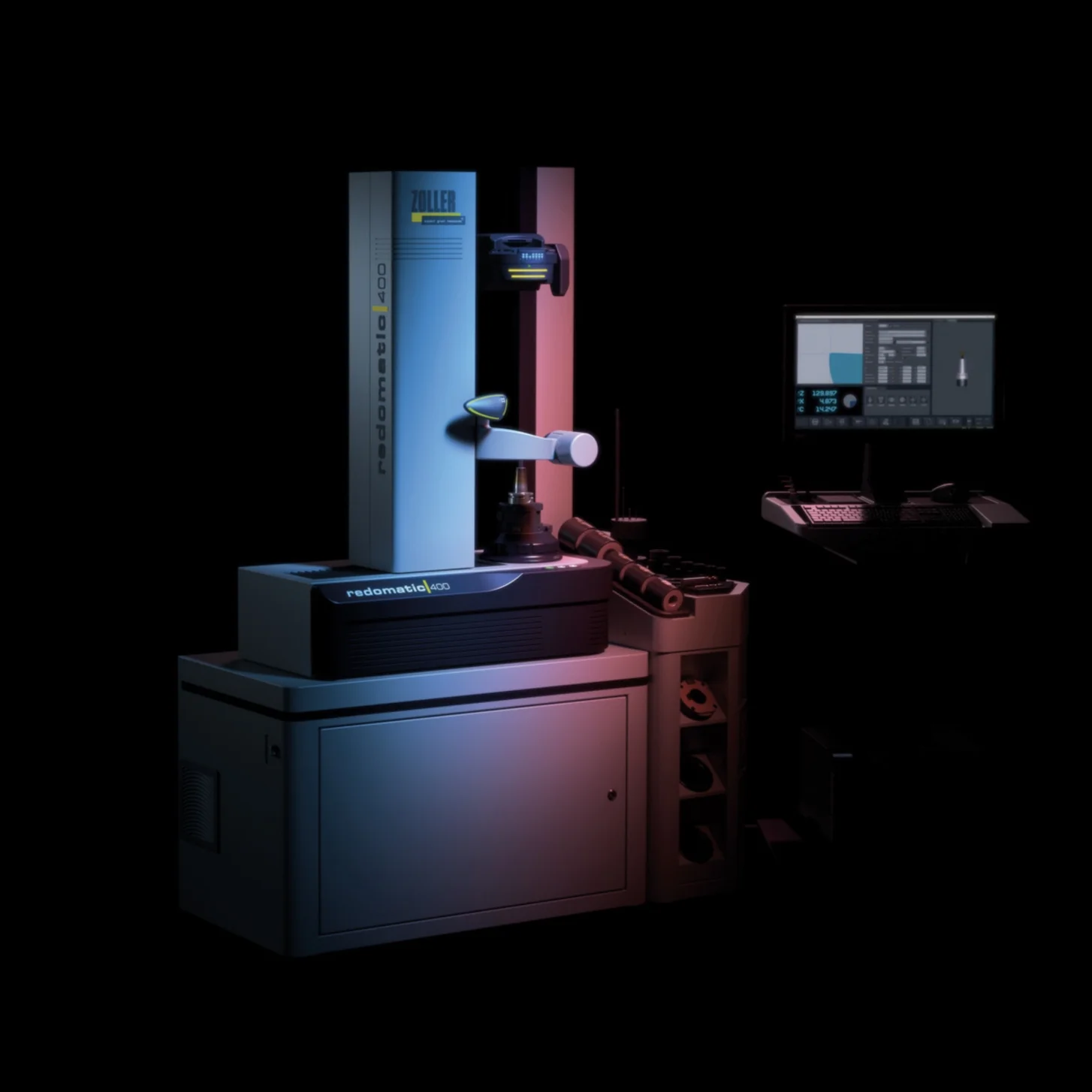

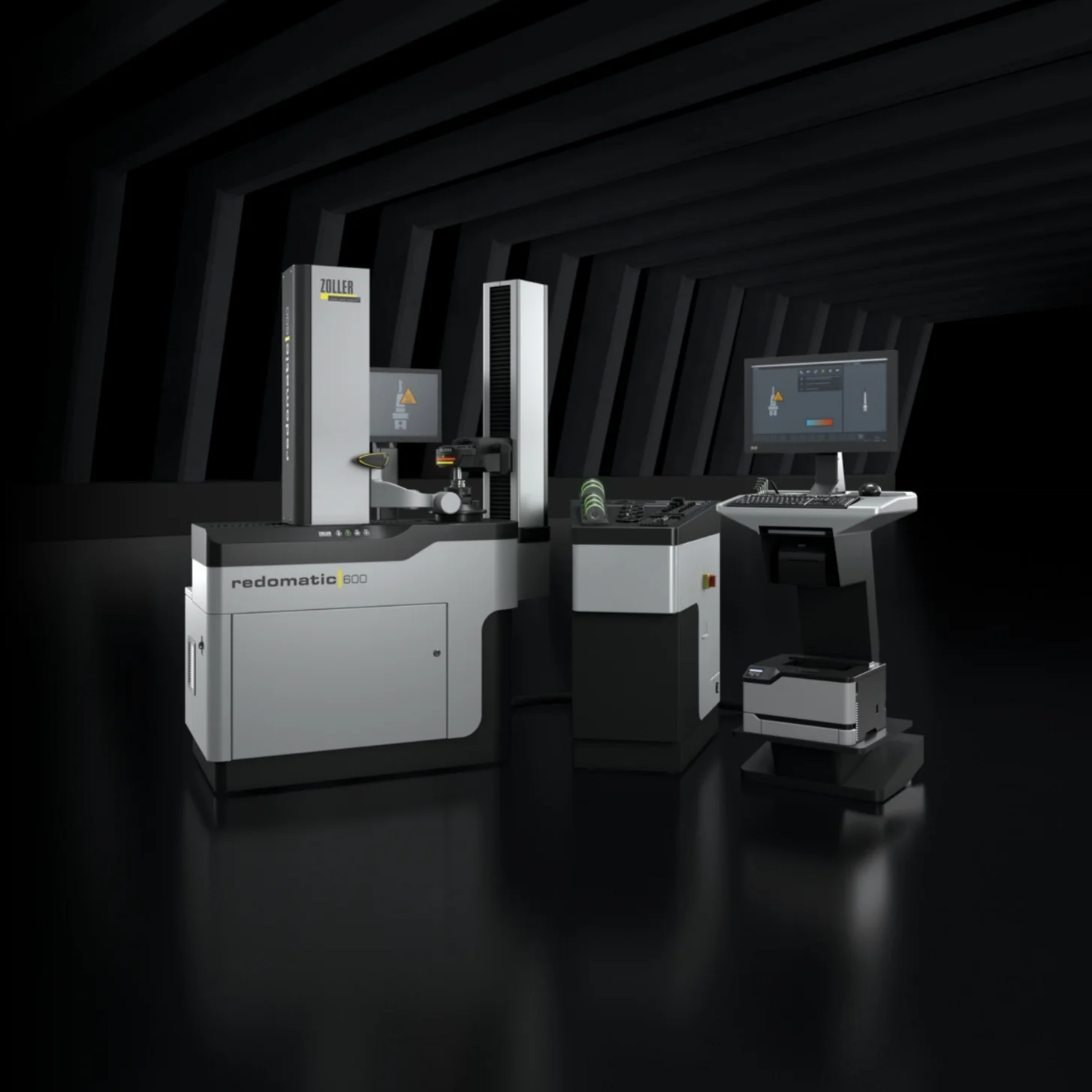

With a »redomatic 400« or »redomatic 600« from ZOLLER, you will produce more effectively with your multi-spindle machines and in your automated series production. Because with »redomatic« you can be sure that the tool lengths are always set correctly. The shrink sequence developed by ZOLLER with the »masterPiece« setting adapter is both quick and easy.

ZOLLER Re-inventing the induction coil

Shrink technology

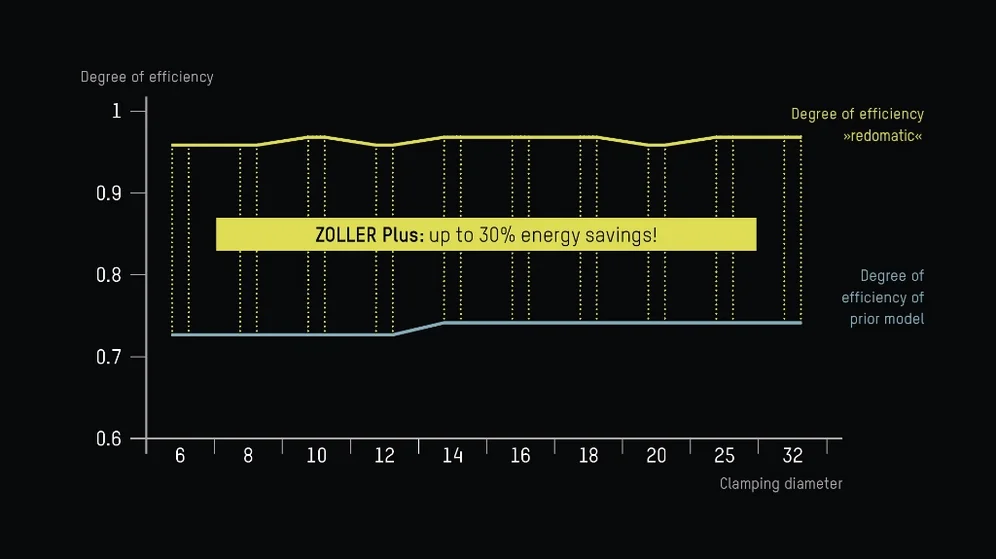

Smart design for maximum efficiency

The ZOLLER induction coil is an intelligent, well thought-out highlight of the »powerShrink«. Two windings connected in parallel within the coil can be activated separately and controlled differently depending on the clamping diameter and length. This enables optimum energy input into the clamping area, accelerates the heating and cooling process and protects your tool holders.

Induction coil with »varOct« shielding system Stand-alone solution »powerShrink«

The high-performance interaction

Flue gas extraction

Fume extraction

Reliably removes fumes from the operator's working area. The established and patented fume extraction system above the induction coil has been extended to include an integrated extraction system inside the coil housing. The fumes are thus extracted directly where they are produced.

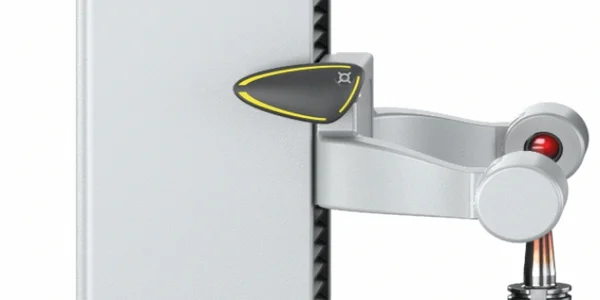

Induction coil »varOct«

Intelligent induction coil with »varOct« shielding system

With automatic diameter adjustment up to a shaft diameter of max. 32 mm for optimum heating power. The heating process is continuously monitored. The inner diameter of the »varOct« shielding system can be quickly and automatically adjusted to the desired diameter using a grid. Thanks to the maximum internal diameter of 45.8 mm, tools with larger cutting diameters can also be easily shrunk.

Optionally also available with a quick-change interface for fast coil changes from 14 kVA to 22 kVA.

One-hand operating handle »eQ«

One-hand operating handle »eQ« (ergonomic & quick)

The optics carrier can be quickly and easily moved to the correct position in Z and X simultaneously with one hand. Additional functions from »pilot 4.0« can also be integrated into the additional button on the »eQ«.

»Asza« length stop system

Automatic length stop system »asza«

In the Z-axis for shrink-fitting to an accuracy of less than 10 μm.

Shrink length monitoring - for safe and controlled shrink-fitting of tools with monitoring of the minimum shrink-fit length.

High-precision spindle »ace«

High-precision spindle »ace«

High-precision, universal spindle system with machine spindle-like clamping behavior, guarantees the μm-precise holding and clamping of tools. The universal attachment holder change system enables adaptation to almost any tool holder system.

Cooling bells

Innovative cooling bells with operator guidance »coolbyLight«

For a safe and easily guided cooling process thanks to the color system of the LEDs. Alternatively, the »redomatic 600« can also be selected with the standard cooling bells.

Cooling manager software for the cooling unit - the cooling unit is only switched on automatically when required.

Auxiliary unit

Support unit

For holding the shrink electronics, cooling bells, mounting rings, stop bars and the ZOLLER »masterPiece« setting adapter. The display of the »sls« shrink guide system in the image processing software ensures that the required accessories can be selected quickly.

The »sls« - »pilot 4.0« shrinkguidance system guides the operator safely and quickly through the shrinking process with the help of precisely predefined work steps in the software.

»Pilot 4.0« image processing software

IPC with »pilot 4.0« image processing software

The control system consisting of IPC, »pilot 4.0« and 24" TFT color monitor takes over all processing tasks for setting, measuring and shrinking and ensures safe and easy operation. The monitor can be adjusted in height and tilt, making the software as comfortable as possible to use. The »cockpit« offers space for a keyboard and mouse as well as shelves for label and laser printers, scanners and tools such as Allen keys.