We stand for smart progress

As a tool manufacturer or grinding company, you have to deliver the best quality. The »genius« universal measuring machine provides you with precise measurement data as unmistakable proof of the high manufacturing quality of your products.

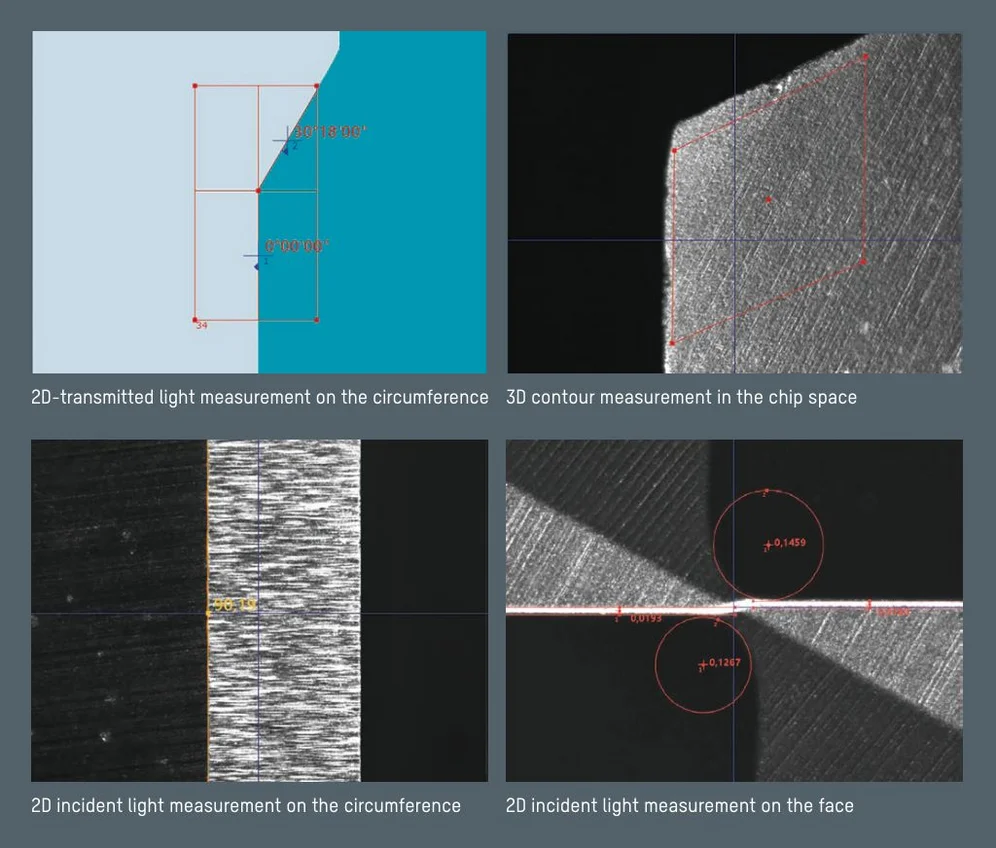

With ZOLLER »genius«, you can measure over 100 parameters of your precision tools in 2D/3D in a non-contact, fully automatic and impressively reliable manner. Every measured value provides you with the basis for improving the quality of your products.

For automated precision

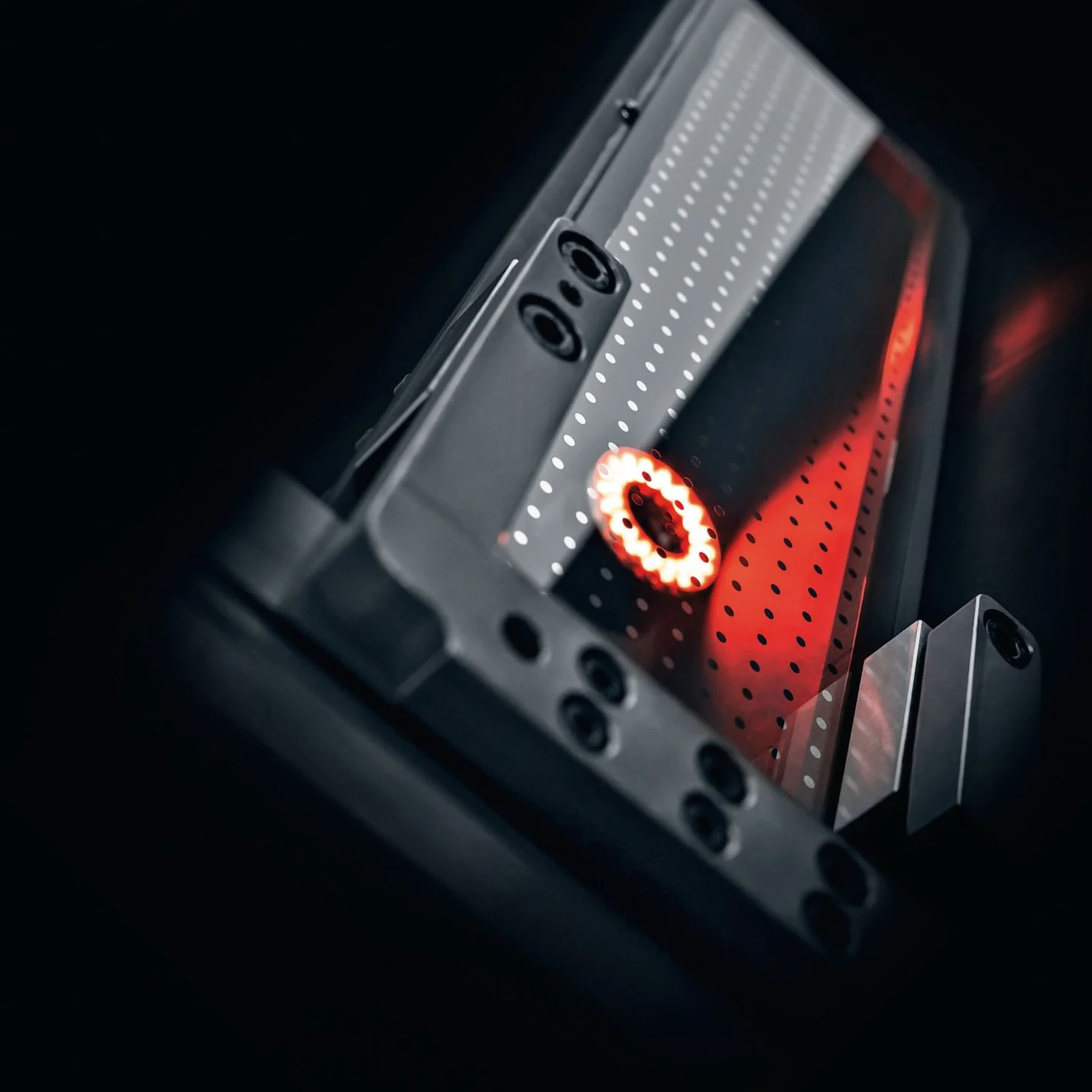

Storage options

Storage options -

for attachment holders and intermediate boxes can be found in the integrated shelves: in the interior for intermediate boxes and on the side for attachment holders. This means you always have your accessories to hand.

»Cockpit« control unit

»cockpit« control unit -

offers the operator ergonomics and comfort through individual adjustment options. The »cockpit« can be adjusted in height and position and the 24" TFT color monitor can also be tilted.

Software »pilot 4.0«

»pilot 4.0« software -

is self-explanatory, clearly laid out and enables the operator to take reliable measurements. It offers a uniform user interface on all ZOLLER systems - right up to ZOLLER TMS Tool Management Solutions. The individual structure of the software allows customer-specific adaptations to be implemented quickly.

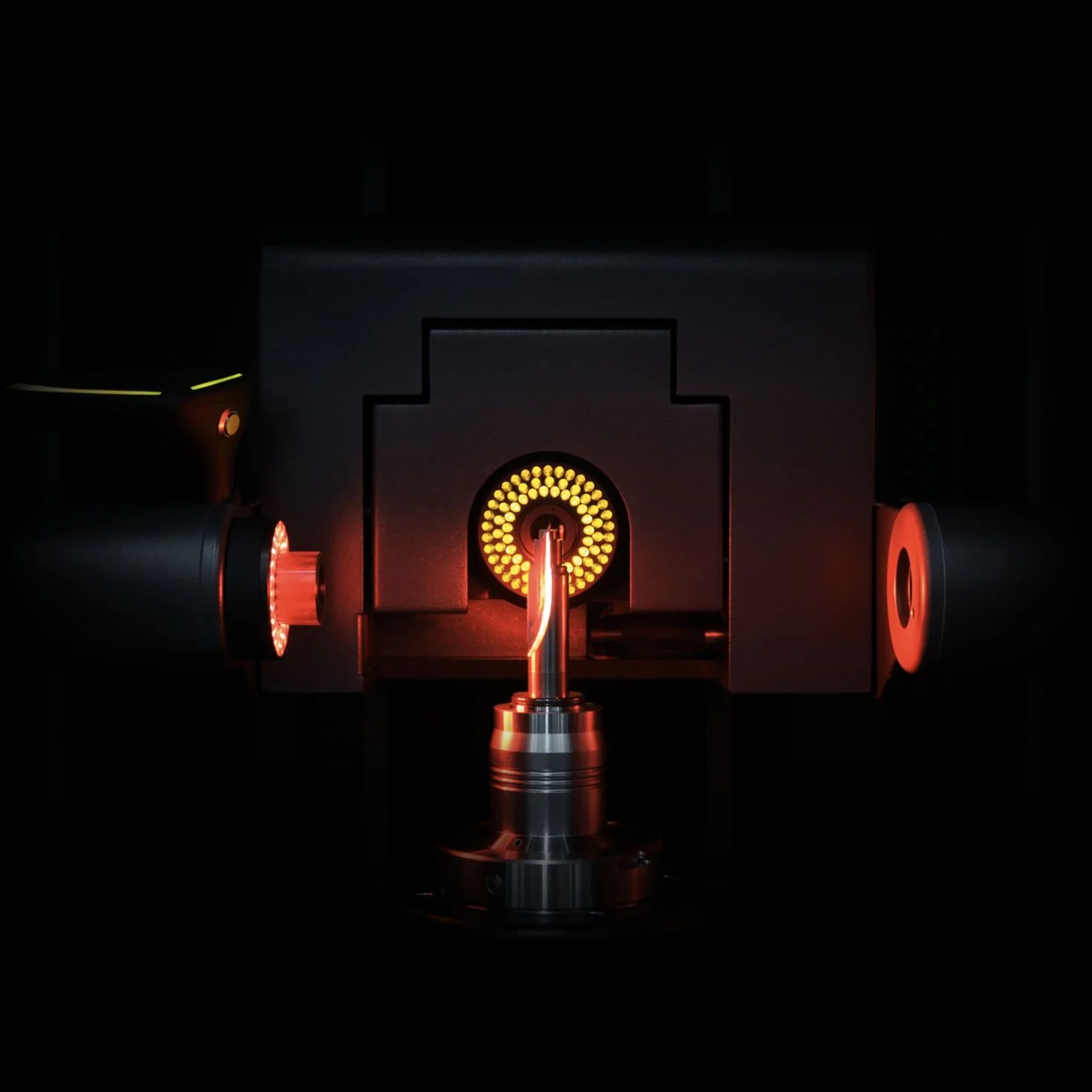

Incident light camera

Incident light camera with multi-LED segment illumination and CNC swivel device -

for the inspection and automatic measurement of tool geometries on the circumference, in the chip space and on the face. Simply enter the target parameters in the measuring program dialog and every measured variable is automatically measured and logged: rake angle, clearance angle, groove contour, chamfer width and many other geometries. The high-performance LEDs, segmented into eight areas, are automatically controlled by the measuring system and ensure optimum illumination of the surface thanks to automatic intensity control - for high precision and repeat accuracy.

Switch cabinet

Switch cabinet -

with active ventilation. All necessary electronic components are carefully and safely installed to ensure trouble-free operation. The position of the control cabinet allows optimum accessibility for maintenance and service work.

High-precision spindle »ace«

High-precision spindle »ace« -

guarantees μm-precise holding and clamping of all types of tools and holders. Adaptation to many tool holder systems is guaranteed by the universal attachment holder changing system. The CNC drive with autofocus and precise angle measuring system offers automatic focusing of the tool cutting edge and recording of the cutting contour.

Transmitted light camera

Transmitted light camera with multi-LED illumination -

With high-quality, low-distortion optics and telecentric transmitted light, it enables the μm-precise measurement of cutting edge contours and step geometry in the silhouette with up to 5 Mpx. The camera has a high frame rate for fast focus and contour recording from the tool rotation. The multi-LED ring light ensures high-intensity and high-contrast illumination of the cutting edge inspection in incident light.

Ergonomic one-hand operating handle »eQ«

Ergonomic one-hand operating handle »eQ« (ergonomic and quick) - to

to easily move the measuring axes to the correct position in the X, Y and Z directions. The button with the Solutions symbol can be individually configured with additional practical functions, making operation even easier and more convenient.

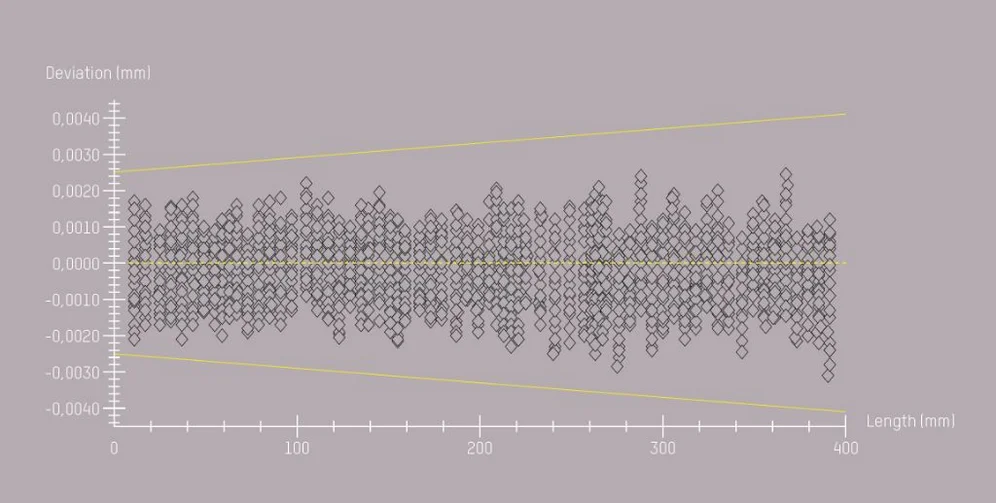

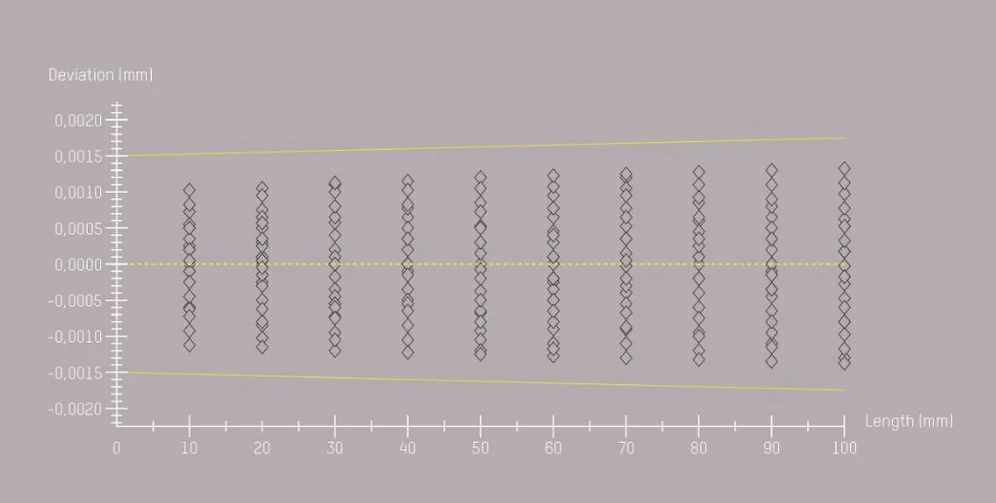

Guaranteed accuracy

The demands in quality management are constantly increasing. That is why you must be able to rely on the constant measuring deviations of your machines. In ZOLLER measuring machines, high-precision calibration standards made of Borofloatglas® are used to determine the length measurement deviations in accordance with the DIN EN ISO 10360 standard. In accordance with this standard, at least three measuring sequences (25,326 relationships) are carried out. With this procedure, the accuracy of the ZOLLER measuring machines is documented in two dimensions and can be traced at any time.

Fact check for tools

Quality is measurable. That's why it's provable. For tool manufacturers and grinders, there is a very simple way to provide hard evidence of tool quality: testing and measuring technology from ZOLLER.

Take exact samples right next to the grinding machine. Check the quality parameters for cutting edges and roughness with a precision of up to 0.1 µm. Have tool geometries analyzed automatically using over 100 parameters and create digital twins.

The ZOLLER Solution Inspection & Measuring proves what many claim: quality.