Scalable savings potential per CNC machine per year*:

15.000 €

* calculated for 20 tool changes per 3 min. change time,

200 working days/year and one shift per day, machine hour 75 € each

Presetting and measuring outside the CNC machine fundamentally changes the way you manufacture. You will significantly reduce setup times, reduce scrap, increase tool life, and lower manufacturing costs. There are many good reasons to choose ZOLLER presetting and measuring machines.

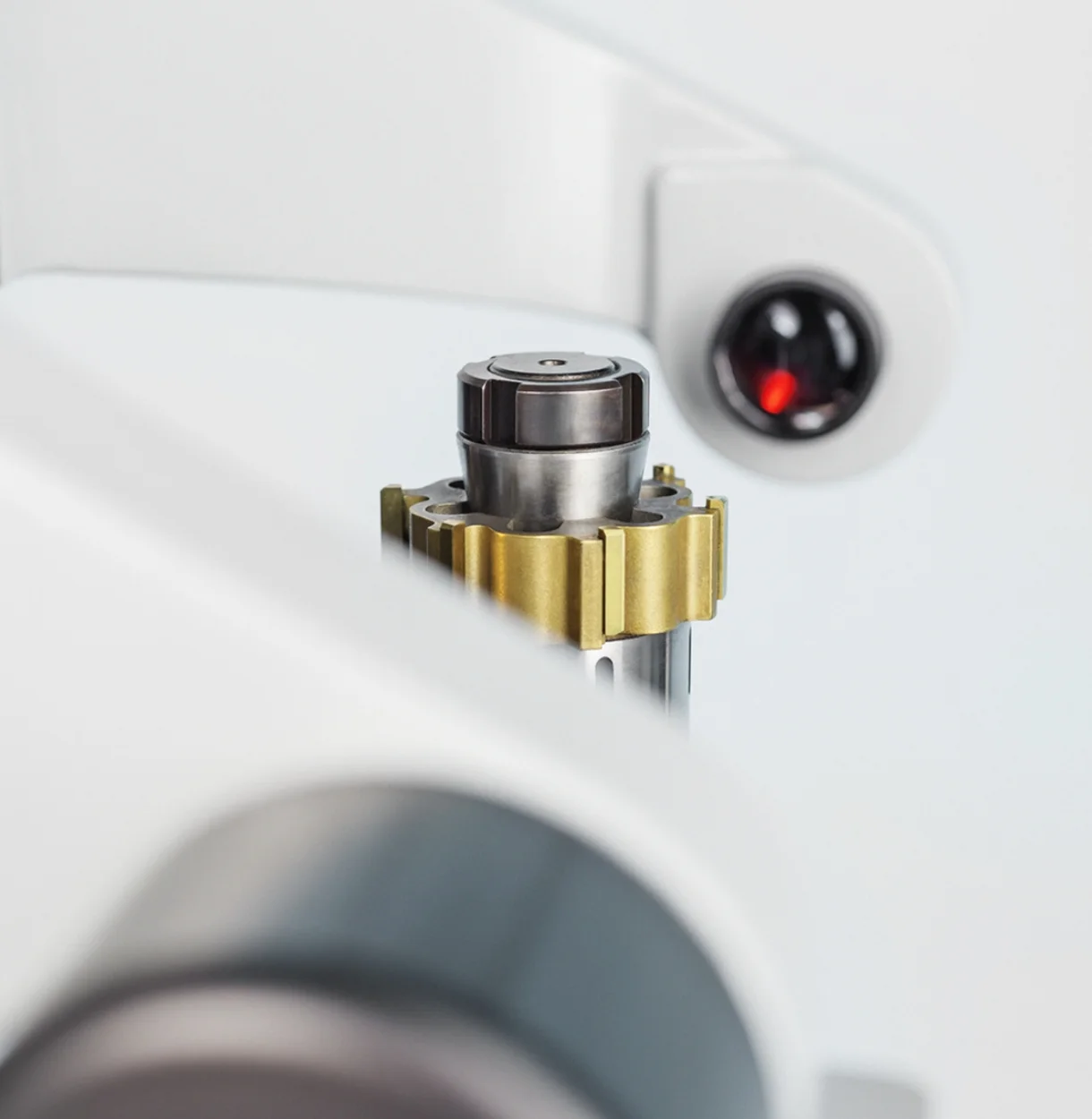

For machining operations, exact tool measurement data is essential to achieve reliable processes and first-class results. ZOLLER's presetting and measuring machines deliver this data with µm precision. ZOLLER goes one step further. The devices are so simple to use that every measurement always produces exact measured values, regardless of the operator.

Presetting and measuring with ZOLLER means that you shift the responsibility for the result from the human being to the measuring machines. In view of the shortage of skilled workers and high cost pressure in manufacturing, having tools measured by a ZOLLER device is the best decision.

If you measure just five tools on a ZOLLER presetting and measuring machine before the tools are placed on the machine, you reduce the set-up time by more than 40 %.

Set-up parallel to machining time with ZOLLER opens the way to high savings potential. Depending on how many tool changes are required, the cost savings per shift and CNC machine can amount to 15,000 euros per year. Depending on the presetting and measuring machine and the configuration, your investment can pay for itself in just a few months.

The measuring technology of a CNC machine usually only records the tool length. This is not enough to exploit the high precision potential of a machine.

ZOLLER provides you with detailed geometry data that enables CNC machines to produce even more precisely. Highest quality from your production.

With a presetting and measuring machine from ZOLLER, you know even before a production run whether a tool is still intact or not. By setting and measuring, you can regularly check the cutting edge quality. You prevent unproductive tool changes and make full use of the tool life. Setting and measuring with ZOLLER increases the efficiency of your production.