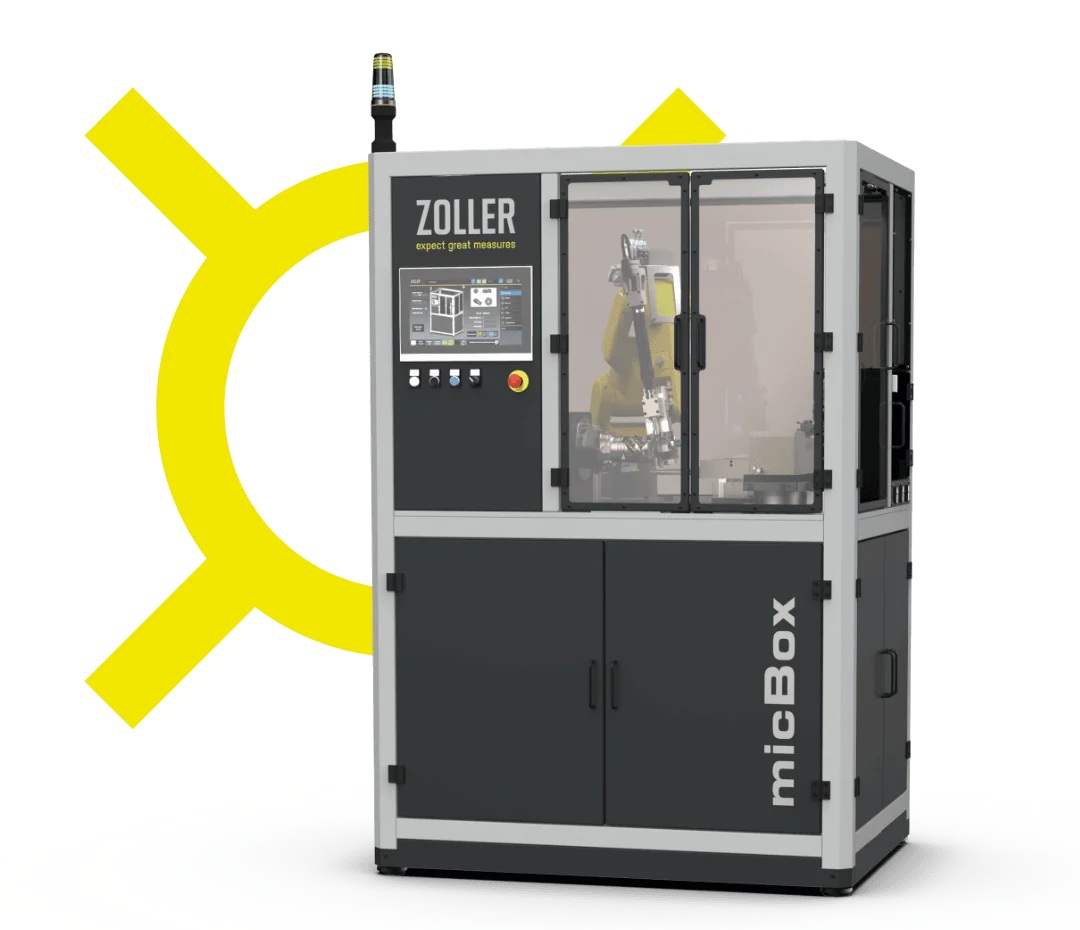

ZOLLER »micBox« – Vollautomatischer Wendeschneidplatten-Wechsler

We stand for smart progress

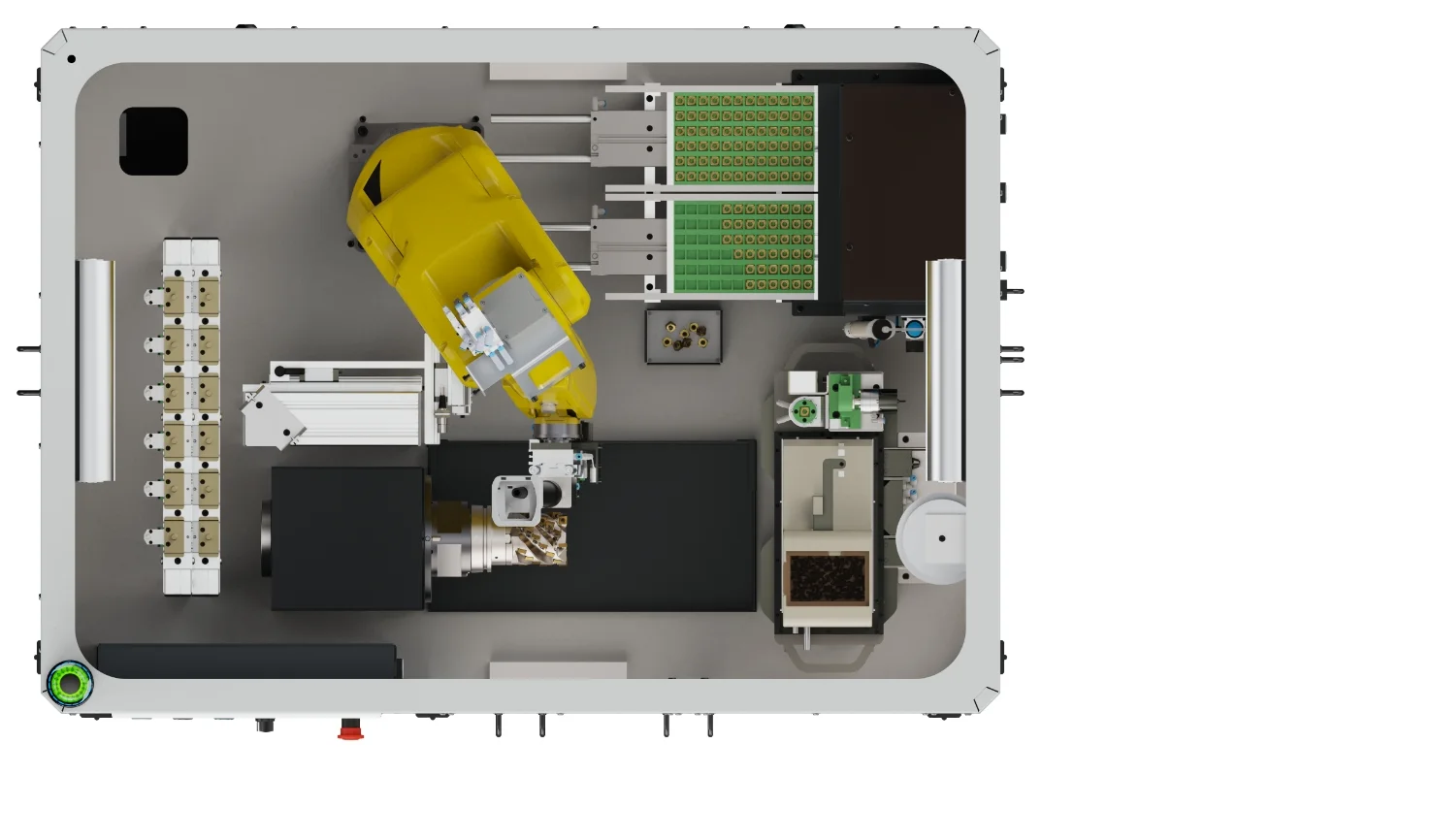

The »micBox« is the fully automatic ZOLLER system for mounting, turning, flipping and changing indexable inserts on milling tools - unmanned and therefore absolutely reliable. Processes that were previously performed manually can now be carried out precisely and error-free, making the »micBox« a game changer in your production.

System solution in detail

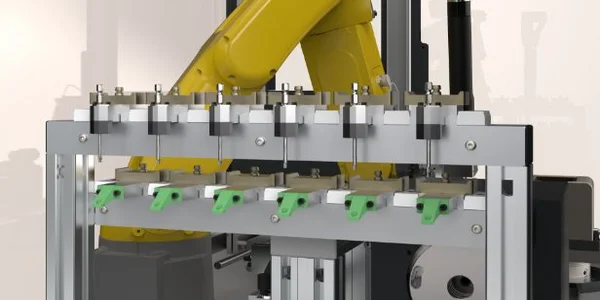

Multiple gripper magazine

Gripper magazine -

which can store up to six grippers for different reversible cutting plates.

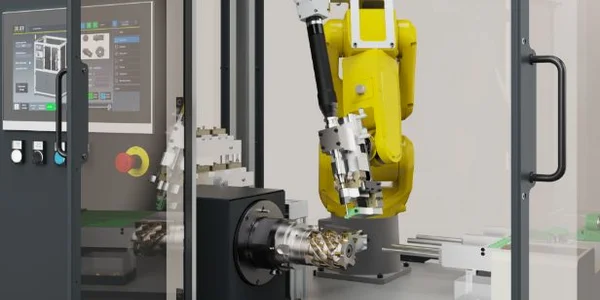

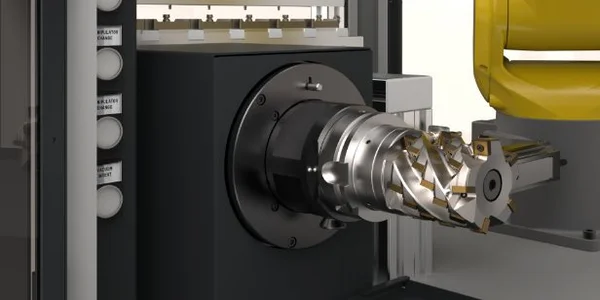

Agile 6-axis robot

6-axis robot -

from Fanuc with which the indexable inserts and screws are precisely changed.

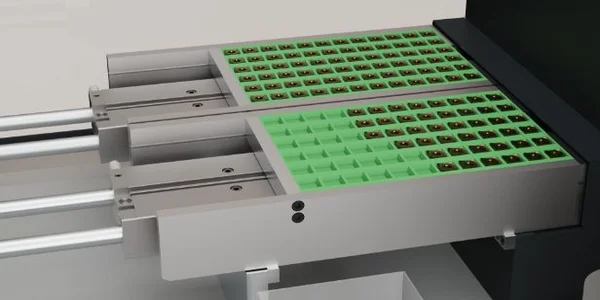

Integrated magazine for indexable inserts

Magazine for indexable inserts -

offers sufficient space. The two magazines within the »micBox« can be equipped differently.

Integrated lubrication unit

Lubrication unit -

for screws has a special grease and guarantees easy loosening of the screws using the screw unit.

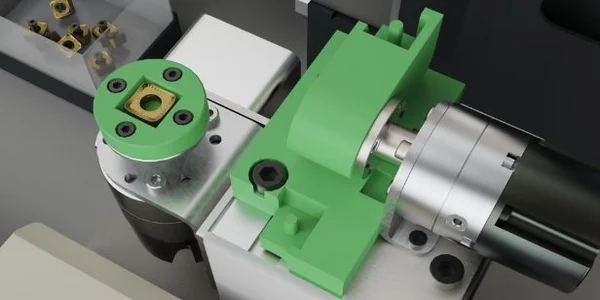

Movable rotating and turning unit

Turning and indexing unit -

is fitted with indexable inserts by the 6-axis robot. This insertion of the indexable inserts into the turning and indexing unit by means of the 6-axis robot ensures that the indexable inserts are realigned. With the screw magazine, a new screw is always used for the tool if required.

Efficient screwing unit

Screwdriving unit -

with integrated vacuum gripper, which is mounted on the robot and always ensures precise changing and tightening of the screws with the correct torque.

High-precision universal spindle

Universal spindle -

enables tools weighing up to 20 kg to be held and also allows tools to be positioned precisely in rotation.

Powerful control software

Control software -

ensures complete operation of the »micBox«. The software can also be displayed on external screens.