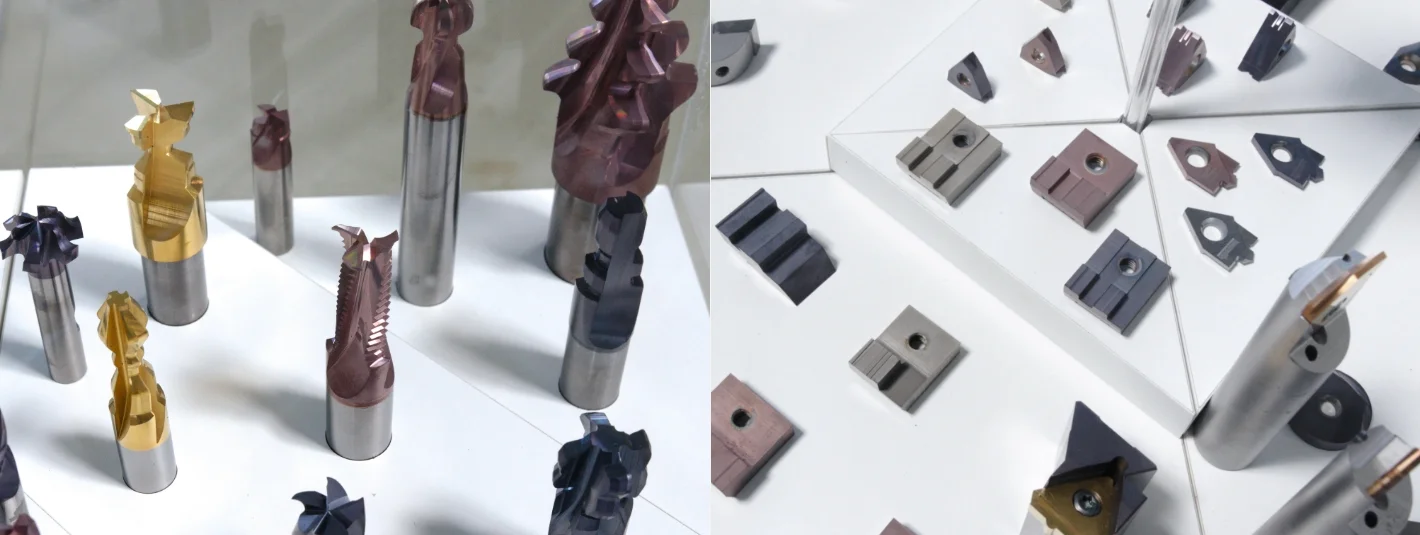

Suitable measuring technology

In his opinion, measuring methods and measuring devices that are also used in manufacturing companies to measure and adjust tools are ideal for measuring tools close to production. "Such measuring devices are designed to be robust for use in production. They also provide the measurement data that users of the special tools determine and verify in production," he reports.

This is why the specialists in Oberndorf measure the geometries of the special tools immediately after grinding on three »genius« tool inspection and presetting machines and a »smartCheck« measuring machine from ZOLLER, among others. "We opted for this manufacturer because the measuring machines and the software are very closely aligned with the company's practice. The specialists in Pleidelsheim know and take into account the requirements of the production technicians," says Michael Mauth. This makes measuring the tools much easier, especially for personnel who are mainly involved in grinding.

Without extensive knowledge of measuring technology, the specialists can use the ZOLLER measuring machines to record and assess whether the ground special tools meet the specifications within a very short time. Operation is also very simple. Operators are guided consistently and reliably through the measuring process using easy-to-understand graphics, useful icons and logically sequenced menus.

Back to overview

Back to overview