Manufacturing companies can work much more economically if they reduce formal organizational effort. This applies, for example, to the procurement and re-procurement of tools from tool manufacturers. Organizing the resharpening of tools at external service providers is also part of the previously time-consuming internal processes.

Christoph Zoller, Managing Director of E. Zoller GmbH & Co. KG in Pleidelsheim, a family and technology company for the efficient handling of cutting tools, says: "With our ordering and resharpening order software modules in the ZOLLER tool management system TMS Tool Management Solutions, we ensure significantly faster, simpler and also reliable, error-free processes in tool procurement. This reduces effort and costs for unproductive activities. This allows companies to work more profitably."

Precise, complete tool data

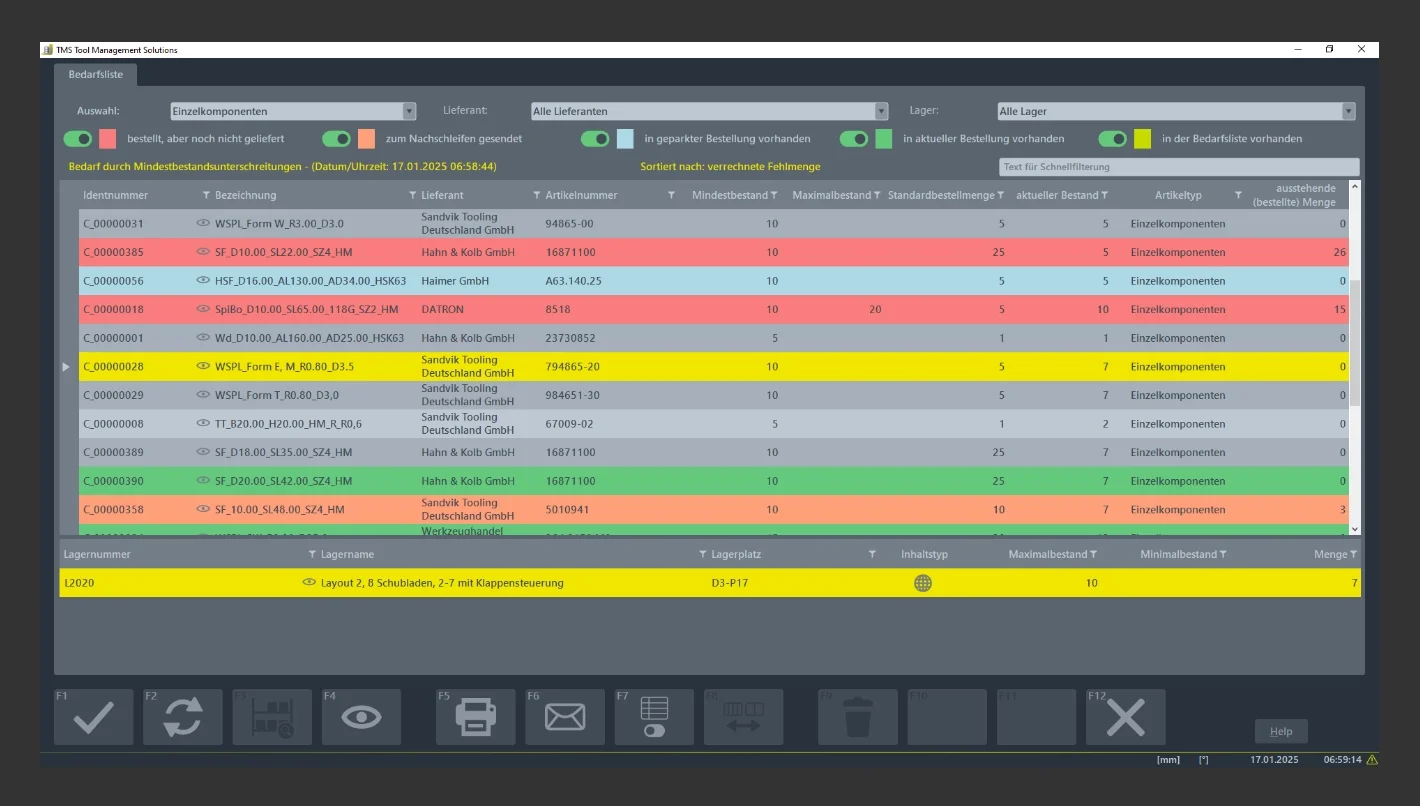

Robin Bender, Project Manager for the TMS Tool Management Solutions software at ZOLLER, emphasizes an outstanding advantage of the ordering and resharpening order modules: "The ZOLLER TMS Tool Management Solutions tool management system continuously provides up-to-date actual stock levels and complete tool data. This means that orders and resharpening orders with the ordering system and resharpening order software modules are reliable and always correct." Time-consuming queries to different departments are no longer necessary. This applies, for example, to the tool store because of stock levels and tool preparation because of correct designations for components. Robin Bender emphasizes: "The ordering and resharpening order software modules automatically transfer the article master data, stock levels, minimum stock levels and - if stored - supplier addresses, costs and procurement duration from the TMS Tool Management Solutions software."

The software module can also be used to generate lists of tools to be procured at any time at the touch of a button based on stored minimum stock levels. After selecting individual tools or an entire list, the ordering system and resharpening orders software modules automatically generate the order orders to suppliers or, as an option, orders to external resharpening companies. All you need to do is enter a cost center.

Flexibly configurable

The ordering and resharpening orders software module can be quickly and easily adapted to the individual formal requirements of different manufacturing companies. The formats of lists of tools to be procured, their contents and the dates or events for automatically generated lists can be freely parameterized. For example, lists can be generated and displayed at time intervals - daily, weekly - or when stock levels fall below a minimum. Additional lists of tools to be procured or regrinded can also be generated and displayed manually at any time. Additional criteria can be specified for this - for example, the type of tools and cost centers in the company.

The operating personnel can specify individual formats for e-mail, print templates and data records for order orders to be issued automatically. They can also freely determine the content of the order requests. For example, in addition to internal designations and article numbers, designations and order numbers, costs and packaging units (if available in master data) of the respective manufacturers can also be included in orders.

The ordering and resharpening orders software module is also flexible with regard to the quantities of tools in the inventory of the ZOLLER TMS Tool Management Solutions software. If, for example, there is an additional requirement for individual tools (over and above stored minimum stocks) for production orders that vary at short notice, the specialists can manually create and send out additional orders. The stored minimum stock levels remain unchanged.

For maximum flexibility, purchase orders can be created and saved until further criteria for sending out a purchase order are met. For example, manufacturing companies can take minimum order quantities into account. They can also benefit from discount scales and minimized packaging costs for combined deliveries thanks to orders that can be flexibly scheduled.

Directly or via a commercial organization

When sending orders, manufacturing companies can choose the process that best suits their needs. On the one hand, the software module can send the recorded and initiated orders to manufacturers as a data record, as a printout on paper or as an e-mail. On the other hand, it can also generate data records with freely selectable content from the proposed orders and send them to a higher-level ERP system. This makes the ordering and resharpening order software modules suitable for small and medium-sized companies in which individual specialists are in direct contact with manufacturers and resharpening companies. On the other hand, larger companies with separate technical and commercial organizational structures can also benefit. In the latter case, the commercial departments receive complete and, above all, reliably correct information on the tools to be procured. This ensures carefully coordinated cooperation and maximum process reliability for internal workflows. Time-consuming, costly queries or even incorrect procurements are avoided.

Continuous updating

Of course, the ordering and resharpening order software modules record incoming goods. The specialist staff can freely select the other internal processes. For example, storage locations for incoming tools can be specified directly or internal orders can be generated automatically for the relevant departments, e.g. for the tool store with the storage location management software module. This applies to the receipt of goods after procurement from tool manufacturers as well as the re-storage after the return of reground tools. The ZOLLER TMS Tool Management Solutions software automatically updates the entire tool stocks so that the minimum stocks are monitored correctly on an ongoing basis.

Back to overview

Back to overview