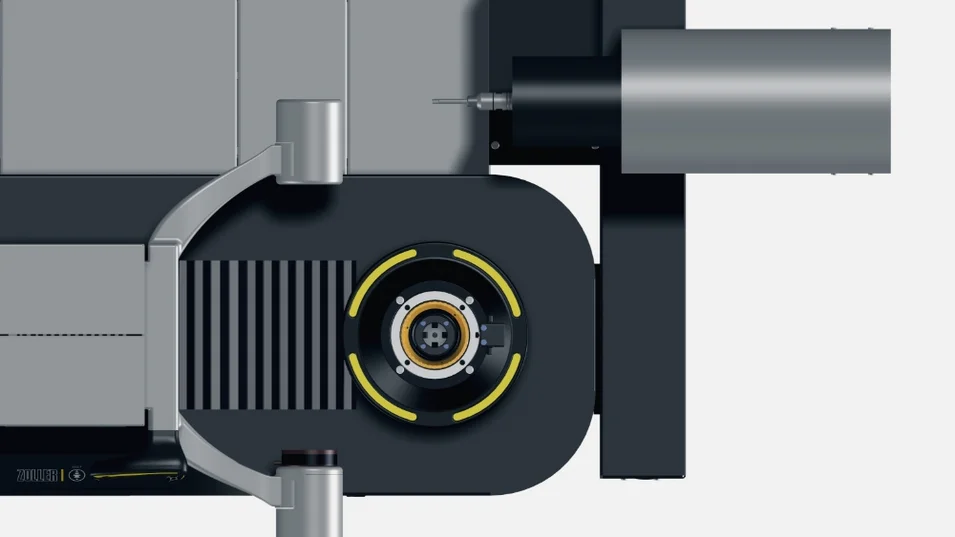

Tool assembly with »screwmatic«

Many tool holders for cylindrical shank tools with a Weldon surface or hydraulic chucks have a horizontally arranged clamping screw. With the help of three CNC-controlled linear axes, the »screwmatic« screwdriving station can move to any horizontal screw position with μm precision. A torque-controlled screwdriving axis carries out the screwdriving process precisely.

Cleverly screwed in

With horizontally arranged clamping screws, the screwing and unscrewing of the screws is automated and the defined torque of the tool systems is set and monitored.

Everything fully automatic

The complete tool is inserted into the setting and measuring tool and the screw-in position is approached automatically. The screw is loosened or tightened under torque control.