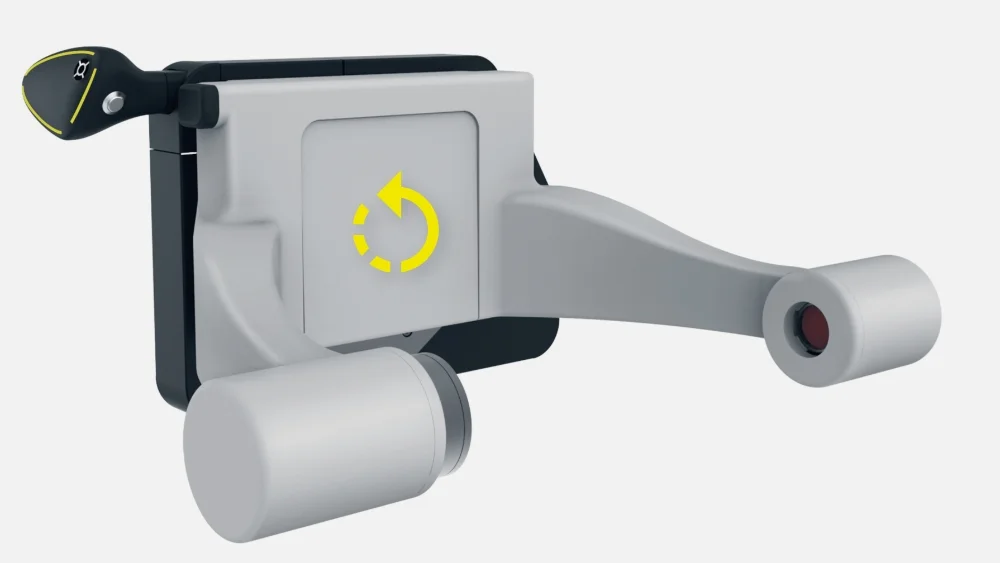

Thanks to the additional Y-axis, the optics carrier can be positioned by up to ± 50 mm from the spindle center in the Y-direction under CNC control. In combination with the turning center measuring camera, this allows turning tools and multifunctional tools to be measured efficiently and with high precision and set to center height.

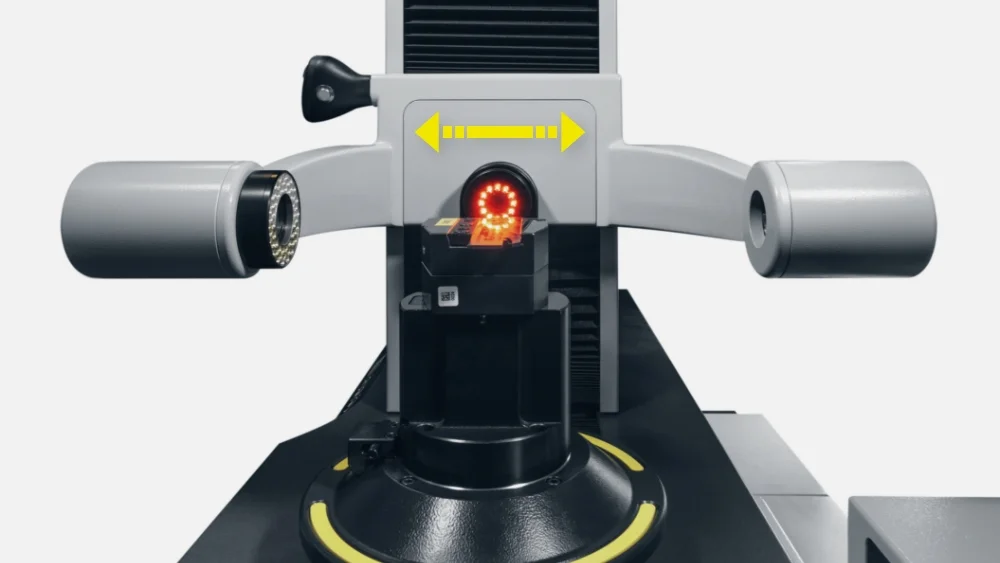

»wearCheck«

Analysis of tool wear through artificial intelligence

Production-integrated wear analysis - ZOLLER shows how progress works with AI!

The »wearCheck« AI measurement function for wear analysis supports the standardized and automated assessment of tool condition based on image processing methods. The software provides a reliable analysis during tool preparation - without additional time expenditure!