»zidCode 4.0« in process

»zidCode 4.0« - Internet of Tools

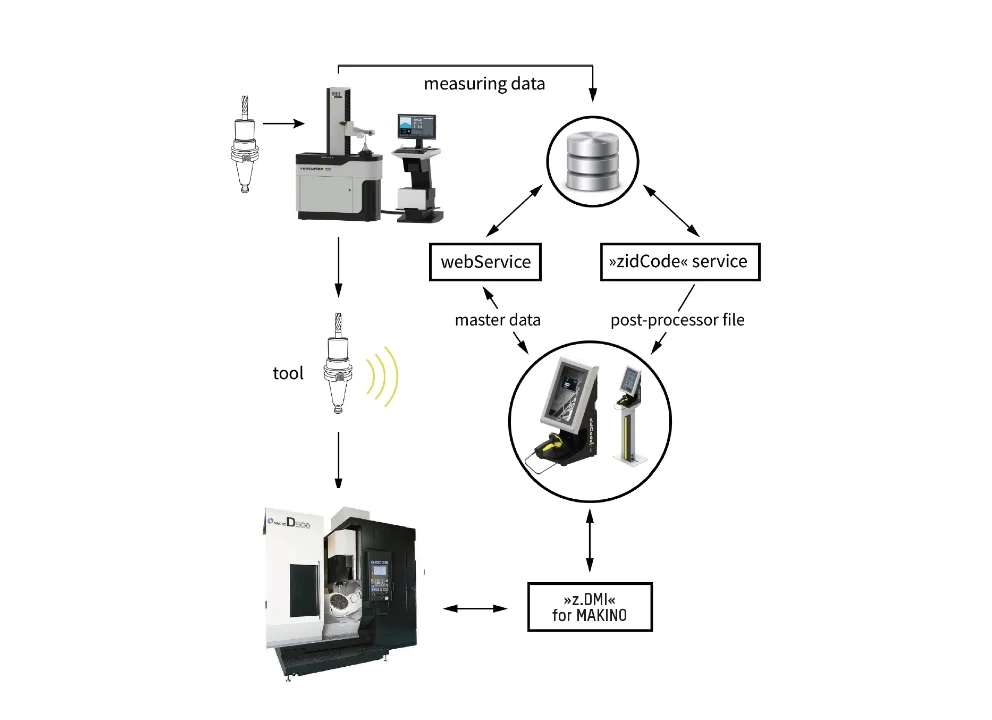

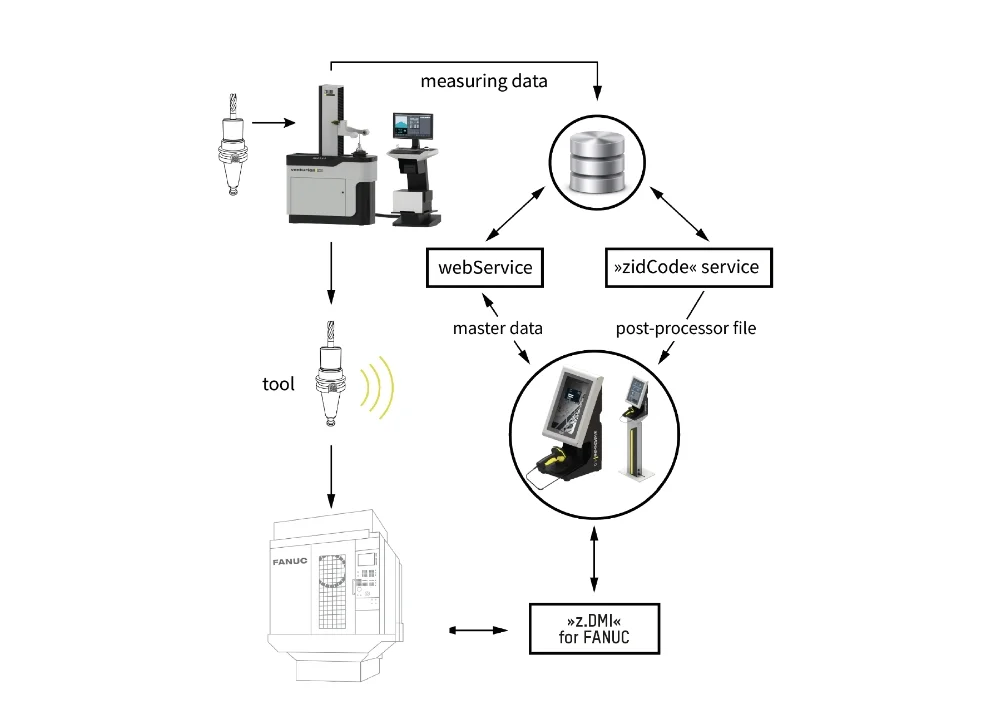

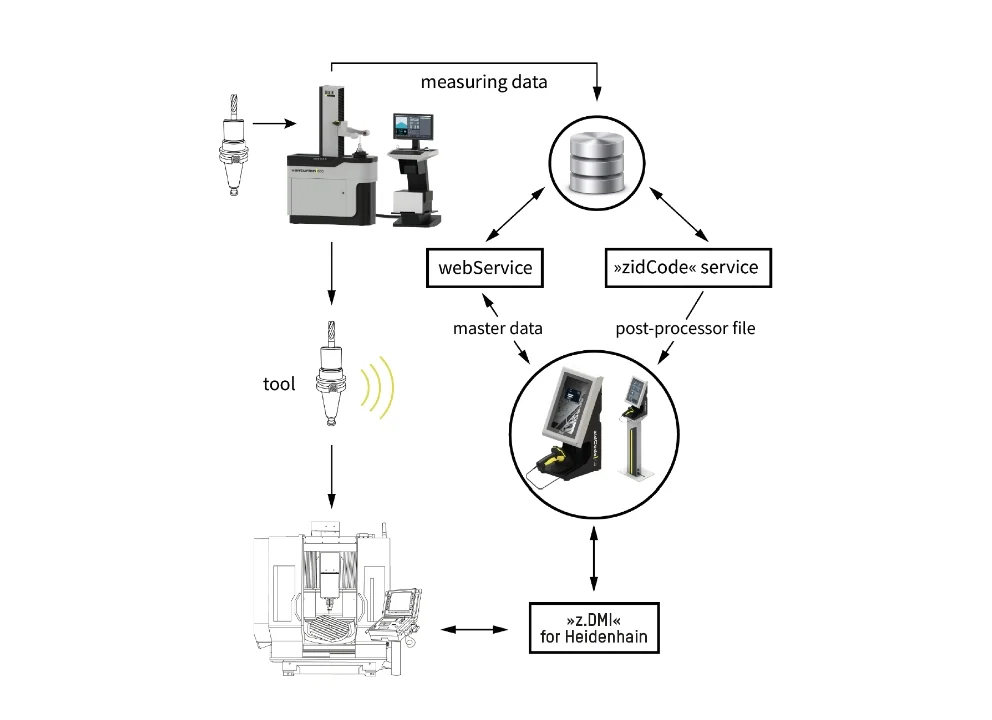

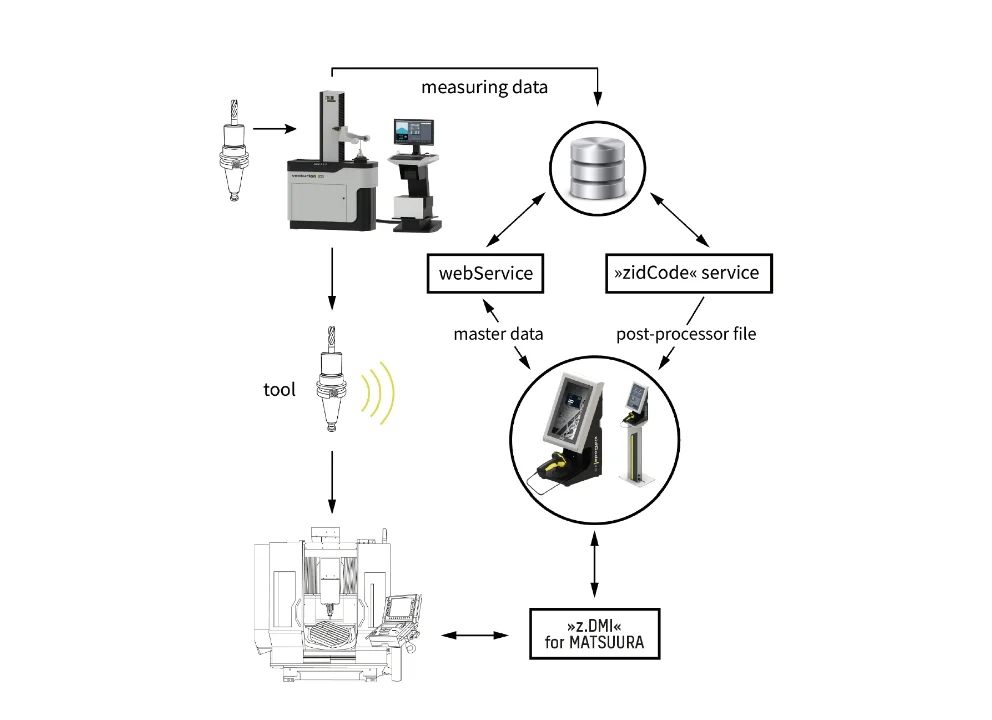

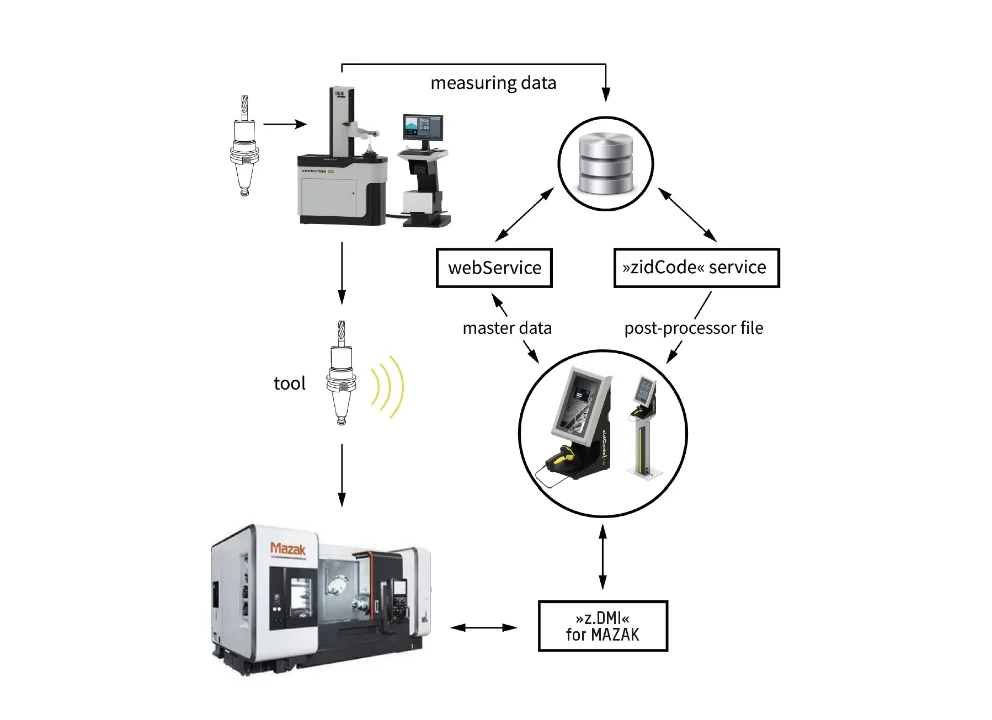

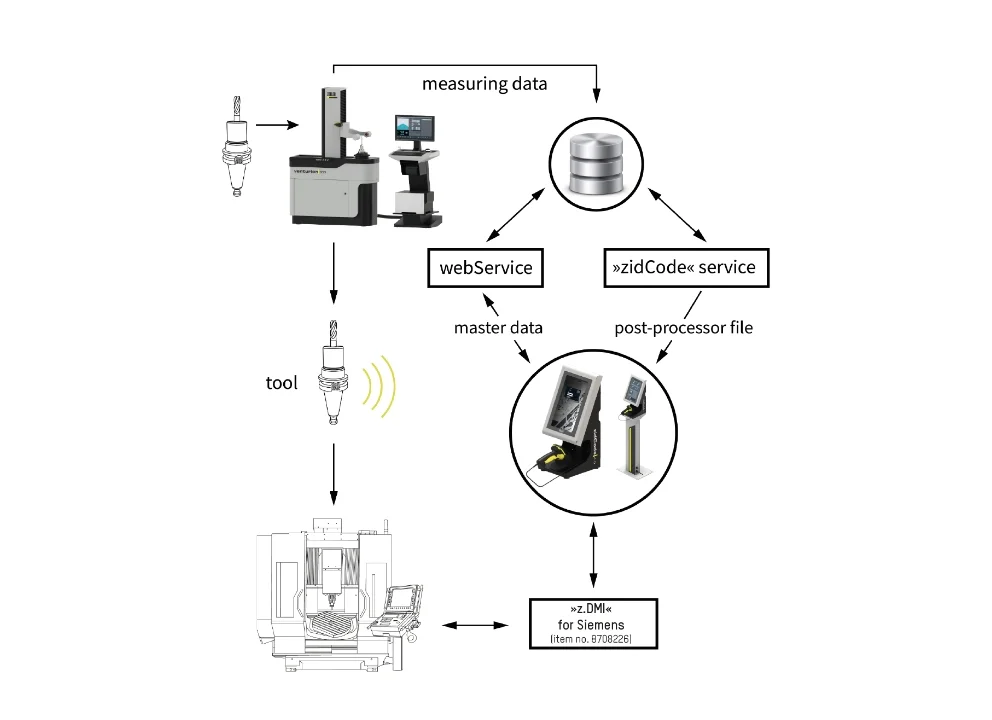

IoT usually stands for Internet of Things. We would like to call it the "Internet of Tools", because you can use the »zidCode 4.0« IoT platform to network your cutting tools with the processes in your production. Thanks to its many output formats, »zidCode 4.0« is compatible with many control systems.

With »zidCode 4.0«, you meet all the requirements for making tool data such as tool life available at all levels of production and digitally recording the entire life cycle of a tool.

For efficient production

ZOLLER »z.DMI« Technology enables the direct transfer of tool data to the tool memory of the machine control and back to the z.One Database.

- Simple operation thanks to automated processes

- Process reliability through centralization of data

- Cost savings through management of tool life data

Automatisierung der Werkzeugvorbereitung mit »cora« und »zidCode 4.0«

Ready for automation

Because »zidCode 4.0« reliably covers the dynamic management of tool data, you are ideally prepared for many technical expansions.

For example,»zidCode 4.0« is the ideal basis for quickly integrating ZOLLER automation solutions into your production at a later date. With ZOLLER, you stay at the cutting edge of technology.

How does »zidCode 4.0« help me to find my tools in a simple way? — ZOLLER »zidCode 4.0«

Minimize search times

Find your tools easily with »zidCode 4.0«.

Our expert tip from the ZOLLER Smart Factory: »zidCode 4.0« is the networked communication platform that records, manages and provides tool data in a closed process. Quick and easy.

Equipment

| Barcode reader 1D/2D per CNC machine |

| »zidCode 4.0« unit including »zidCode 4.0« software package |

| USB stick (documentation, instructions, training videos) |

| Cable kit (Ethernet, power cable) |

| »zidCode« software module for installation on existing ZOLLER presetting and measuring machine |

| Windows services for installation on a server or PC: ZOLLER WebService and »zidCode service« |