If you look at a dentist's hand-held device, you can only imagine how small the motors and drive units inside the device have to be to perform high-precision work at speeds of up to 500,000 rpm. In idyllic Leutkirch in the Allgäu region, SycoTec manufactures precisely these parts, among others, and encounters tricky challenges in the process. However, the company not only manufactures delicate components for dental technology, but is now one of the largest suppliers of high-speed drives in the world. The division covers a wide range of customized electric drives, motor components, turbo generators and special motors.

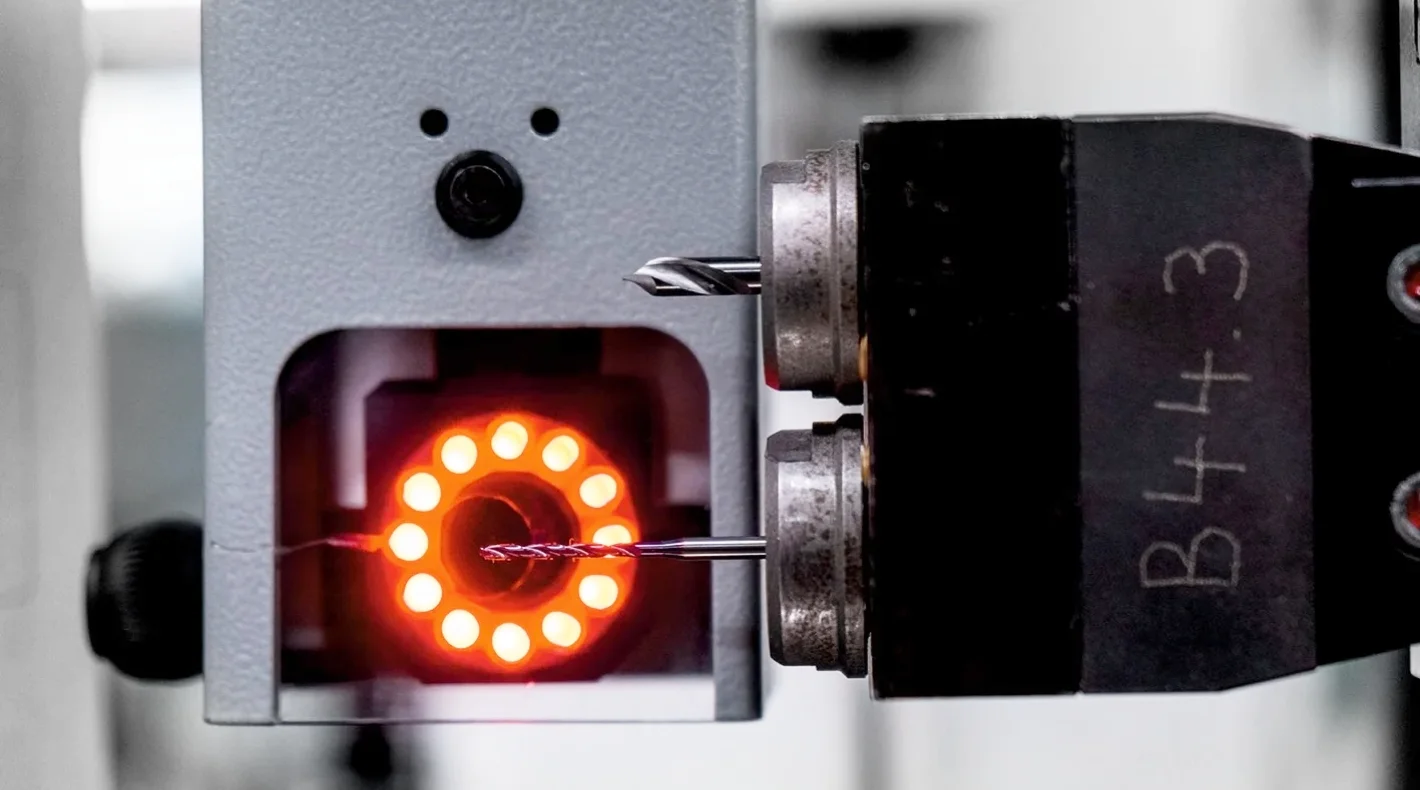

The third pillar, "Components", also requires a great deal of know-how and experience. All technologies such as milling, turning, grinding, honing, laser welding, deep drawing and robot welding are available. Handling the large variety of static and rotating tools used on the numerous machine tools is a particularly great challenge for SycoTec. Furthermore, intricate components with very low tolerances have to be manufactured in small to medium batch sizes - and at the same time with high efficiency.

Back to overview

Back to overview