Short throughput times and maximum flexibility are increasingly required in order for local manufacturing companies to be internationally competitive. However, both can only be achieved in conjunction with reliable processes. Internal processes can be significantly improved, particularly with extensive digitalization. This applies in particular to the transfer of information and data from NC programmers to machine setters as well as the organization and management of tools, devices, measuring and testing equipment. Christoph Zoller, Managing Director of E. ZOLLER GmbH & Co. KG in Pleidelsheim, a family and technology company for the efficient handling of cutting tools, says: "Digitally transferred data has several outstanding advantages. It is usually generated automatically and therefore error-free, it is immediately available to all parties involved and it enables traceable corrections to be made at any time."

Set up CNC machines with process reliability

Above all, the extensive information and data relating to NC programs is transferred digitally from NC programmers to machine setters much more quickly, easily and reliably. This applies to the NC programs themselves and information on required tools and devices as well as materials and dimensions of blanks. Up to now, a collection (folder) of forms and data on paper, which is handed out and passed on manually from NC programmers to machine setters, has been the norm.

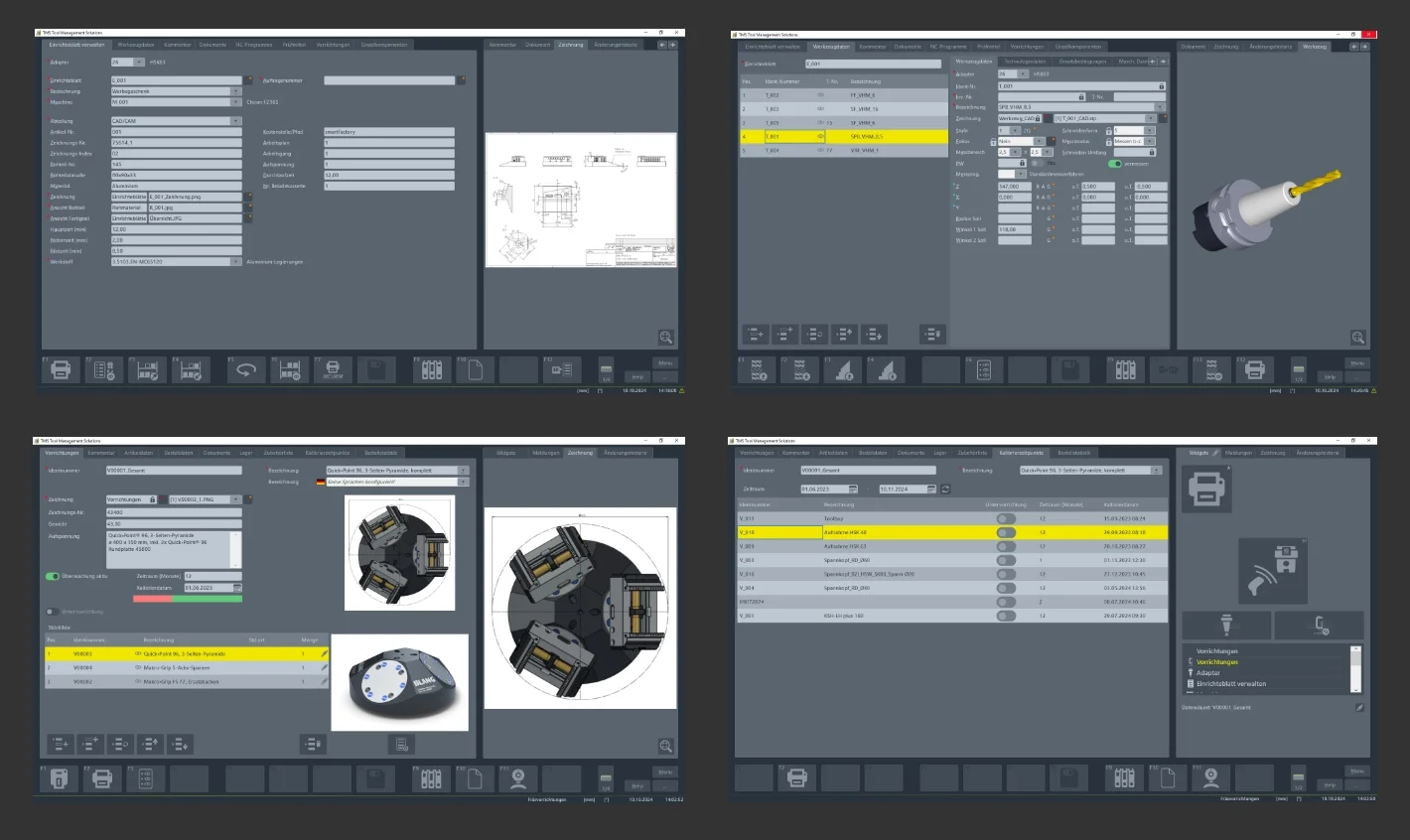

In order to digitize and optimize this process, ZOLLER has integrated the Manage Setup Sheet module into its TMS Tool Management Solutions software. The contents of the digital setup sheet can be flexibly adapted to specific requirements. Thanks to interfaces to 30 different CAD/CAM systems, the setup sheets are largely created automatically during CAD/CAM programming. NC programmers simply select the CNC machine to be used. The digital setup sheets contain NC programs as well as the data required by the machine setter for tools, devices and blanks. As an option, commercial data on main, auxiliary and set-up times can be added. As Robin Bender, Project Manager for the TMS Tool Management Solutions software at ZOLLER, explains, additional information can also be easily integrated into the digital setup sheets. "This includes, for example, comments, drawings, photos and 3D models of fixtures and clamping situations, but also videos of complete processes, such as the setup of clamping fixtures and clamping of blanks," he explains. With this detailed information and instructions, the digital set-up sheets avoid time-consuming queries and tedious searches for the necessary equipment and auxiliary tools, for example. They therefore ensure significantly greater process reliability.

Detailed information on clamping fixtures and tools is contained in the respective ZOLLER software modules of the TMS Tool Management Solutions tool organization. Depending on the expansion level and installation of the entire software, this information can be called up at the touch of a button in addition to the setup sheet. This means that additional information is available to the personnel involved as required. This applies, for example, to the assembly and testing of clamping fixtures as well as the assembly, adjustment and measurement of complete tools. As a result, the specialist personnel in work preparation work much more efficiently and reliably.

Back to overview

Back to overview