Transparent reporting with ZOLLER TMS Tool Management Solutions

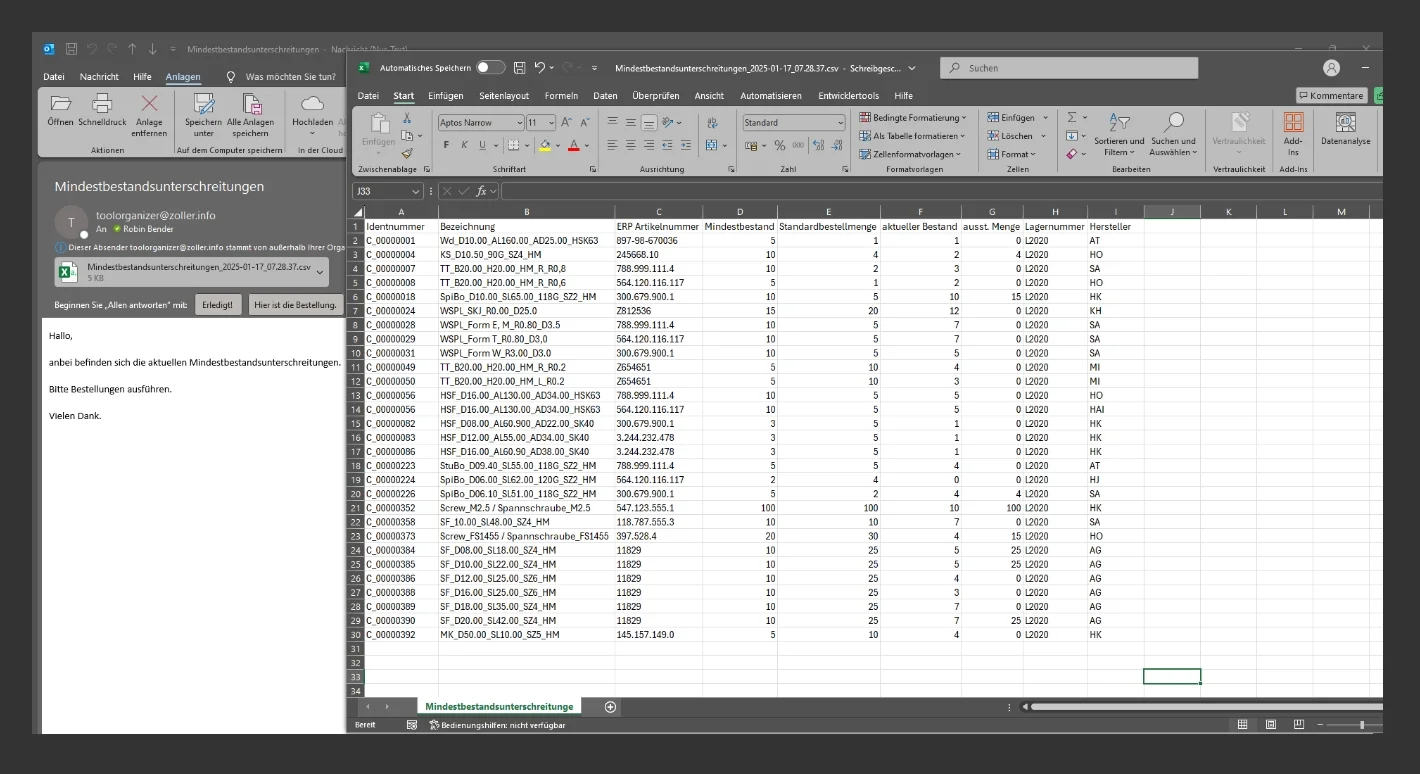

In order to always be aware of a large inventory of tools, measuring and inspection equipment and to be able to reliably plan their use in production, technical and commercial specialists require up-to-date information on an ongoing basis. This can be achieved with the ZOLLER reporting service. Selectable data from a variety of software modules of the ZOLLER Tool Management Solutions software is recorded at programmable intervals and output in various data formats. Robin Bender, Project Manager for the ZOLLER TMS Tool Management Solutions software, says: "Our ZOLLER Reporting Service is easy to use and flexible to configure. The data output can be configured according to individual requirements so that it can be tailored precisely to the needs and specific process requirements. For example, manufacturing companies can choose whether reports are output at time intervals or triggered by events. The latter applies, for example, to the minimum stock level in the warehouse management software module. If the programmed event occurs, the designated persons and positions receive reports and lists in the selected format."

Qualified database for optimization

The information received from Reporting Service is not just for transparency. As Robin Bender emphasizes, it is particularly suitable for optimizing individual processes in manufacturing companies. This applies, for example, to tables created at intervals that indicate minimum stock levels, quantities and frequency of repeatedly procured tools. An accumulation of individual tools can be quickly identified. On the one hand, this can prompt stock levels and minimum order quantities and thus optimize logistics. For example, you can benefit from quantity discounts.

On the other hand, the regular reports can also help to optimize production processes. If, for example, individual drilling, turning or milling tools are procured exceptionally frequently in large quantities, this can be an indication of above-average tool wear during selected machining operations. This provides sound data for technically optimizing these processes in order to work much more economically in the future.

Reliably meeting deadlines

"Manufacturing companies benefit from the reporting service, particularly when using measuring and testing equipment," continues Robin Bender. Measuring and testing equipment must be calibrated at specified intervals. The ZOLLER reporting service makes it much easier to remember this. Once programmed, the function automatically creates reports at intervals, for example monthly or weekly, which contain the measuring and inspection equipment to be calibrated. These are issued to the relevant persons and departments and can also be stored centrally as proof. ZOLLER's reporting service also flexibly creates reports according to individual criteria, for example according to the type of measuring and testing equipment or its measuring method. This provides quick and reliable overviews of calibration dates for specified measuring and inspection technologies, for example for gear measuring equipment or surface measuring devices.

Flexible and freely programmable

Robin Bender highlights the fact that the optional reporting service from ZOLLER can be flexibly adapted to specific requirements in every respect as a particular advantage. For example, the reporting service can send data as an e-mail to designated persons. The text and text format of the e-mail can be created and specified in advance as a template. Alternatively, reports can be created as tables with freely definable column contents in PDF and CSV data formats, among others, and output to selectable data storage devices. The latter applies to storage disks on individual computers and also storage locations in the cloud (accessible via Internet addresses).

In addition, individual reports for specific information can be parameterized and initiated as required. The general specifications can in turn be saved for subsequent reports and retrieved as required.

Benefit automatically

"Another key ZOLLER advantage of the reporting service is that all processes for collecting data and outputting reports, lists and tables run automatically in the background without manual intervention," explains Robin Bender. Selected specialists automatically receive the reports intended for them. This ensures that once processes are deemed necessary, they are continued reliably and continuously. The reporting service also helps to critically examine, assess and improve internal processes on an ongoing basis. The automatically generated reports remind you to use data to repeatedly optimize individual commercial and technical processes. This proves to be particularly profitable for manufacturing companies, as users of ZOLLER's reporting service confirm after a few months.

Back to overview

Back to overview