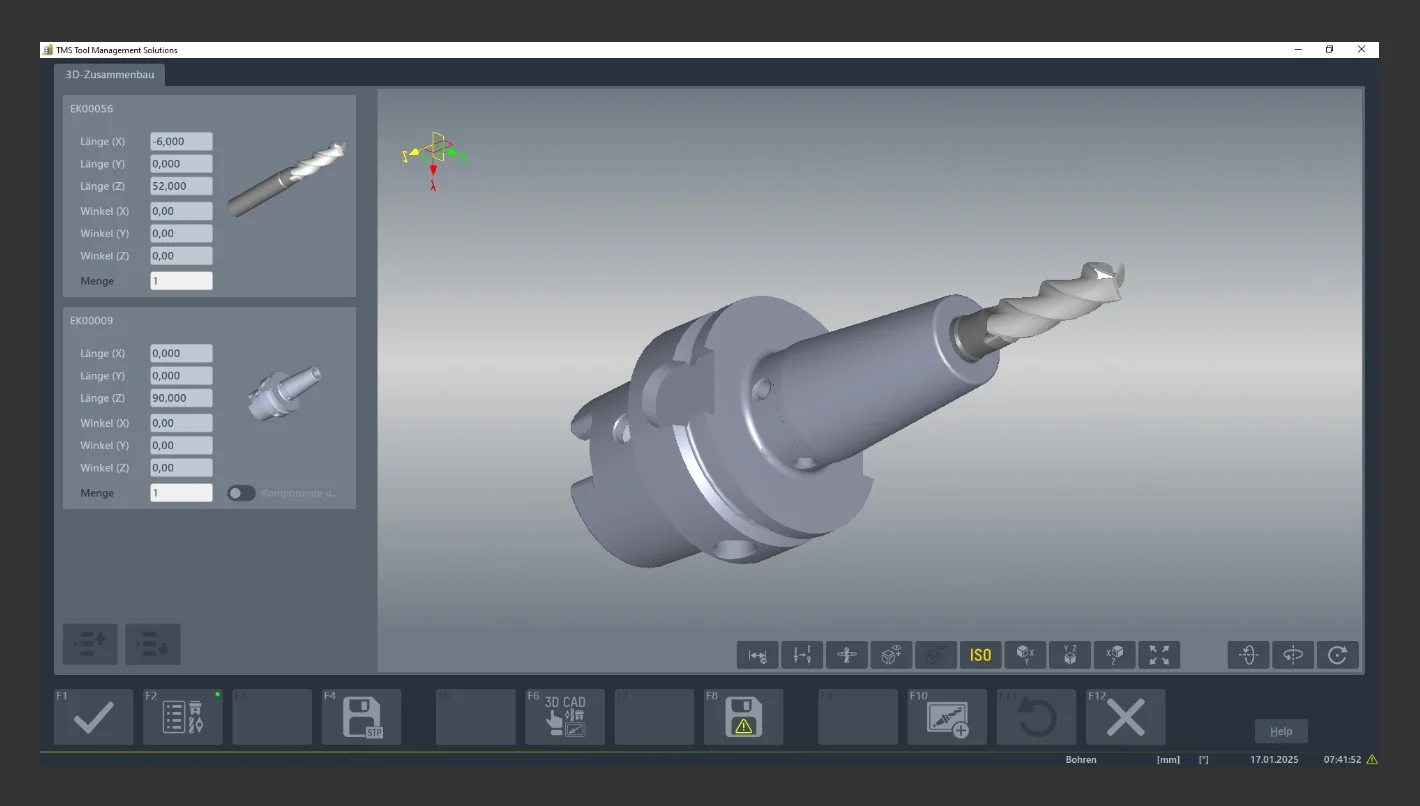

Complete tools consist of several components - usually a tool holder, tool carrier and cutting elements. The component data is usually available in the ZOLLER TMS Tool Management Solutions tool and tool data management system as master data and as 2D and 3D graphics. With the help of the graphic assembly, complete tools can be generated virtually, created and saved as a data record quickly, easily and reliably.

Combine only plausible components

To do this, work planners first select components using lists in the ZOLLER TMS Tool Management Solutions software. This is very easy thanks to a large number of freely selectable search criteria. For example, components can be selected using symbolic graphics according to machining processes, sizes and designs of tool holders (according to ISO and DIN) or according to the required cutting circle diameters for cutting edges.

The additional selectable "interface coding" function proves to be particularly advantageous for fast and reliable selection. It automatically checks the interfaces of the selected components. If the components are DIN-compliant, the individual component library automatically filters out incompatible elements. This means, for example, that tools with Weldon shanks with a diameter of 10 mm can only be combined with holders of the same dimensions and design. This ensures maximum process reliability when assembling complete tools.

After selecting suitable individual components, a 2D graphic including dimensions is automatically generated. This includes lengths over which a shank is to be shrunk or screwed in. The 2D graphic also shows the assumed zero point of the complete tool, which is required for setting and measuring for the NC program.

Photorealistic view

Solid models of the complete tools can be created at the touch of a button. The 3D models created are then saved in the ZOLLER »z.One database«. These graphics serve as the basis for programming in the respective CAD/CAM systems.

A large number of CAD/CAM systems can import this data using a ZOLLER interface. Manufacturing companies are therefore independent of the choice of CAM system. They can also switch to other CAD/CAM software simply and easily.

Clear assignment

So that work planners can quickly and easily identify and determine the components required for assembly, the graphical assembly shows the components in different colors in the 3D models of the complete tools. When clicking on the graphics, the software module highlights the relevant components in the parallel lists. This enables assembly specialists to reliably identify these components and assemble them reliably.

Individual expansion

Many manufacturing companies use individually designed tools. These can also be imported into the ZOLLER TMS Tool Management Solutions software. All you need to do is create files in STEP format in the 3D CAD system and save them in the ZOLLER »z.One« database. It goes without saying that the graphical assembly allows the assembly of complete tools of all types for different machining processes. For example, grinding wheel sets and non-rotationally symmetrical turning tools can be automatically assembled from selected components according to the same processes as milling and drilling tools. For components that are designed and dimensioned strictly according to DIN, the system automatically checks whether the interfaces of the components fit together and whether an assembly is plausible. Graphical assembly thus ensures that manufacturing companies work particularly efficiently and reliably when assembling complete tools. This shortens throughput times, increases flexibility and reduces costs.

Back to overview

Back to overview