Specific problem

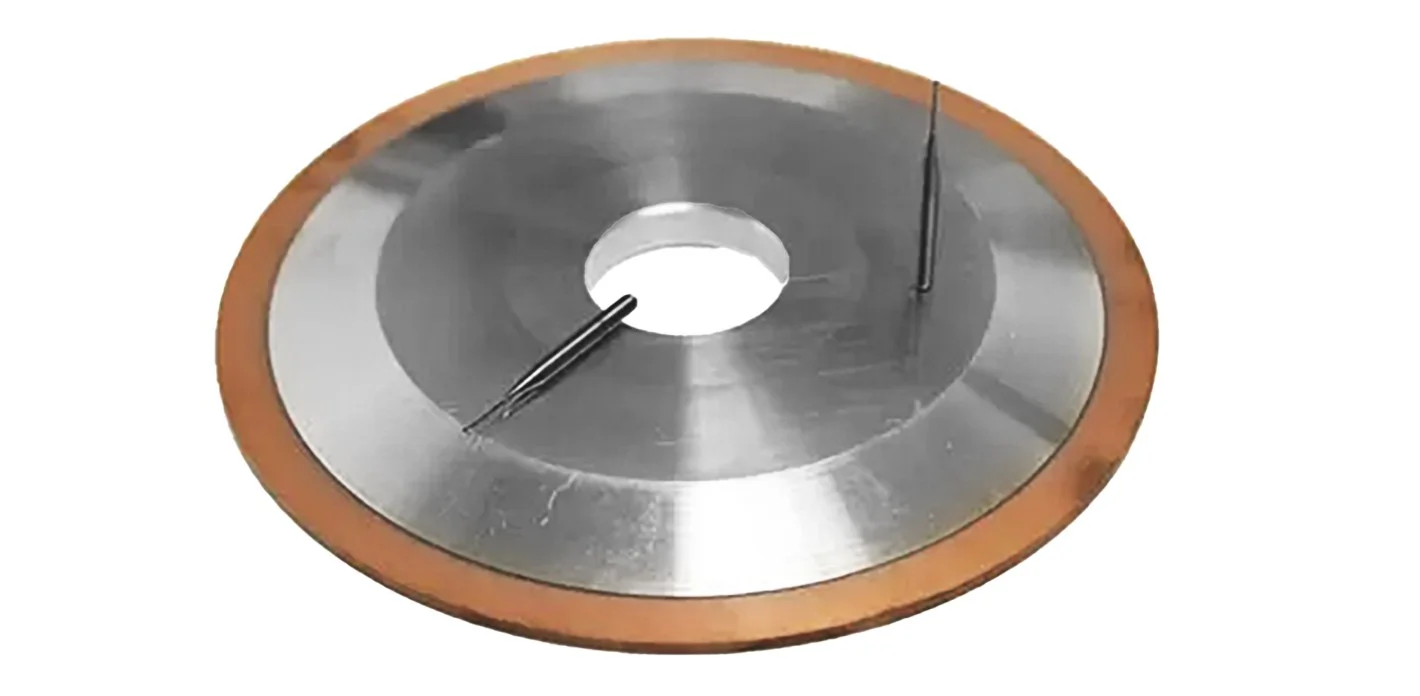

The customer therefore had a specific problem to solve. The grinding wheel did not make contact with the workpiece during the first tool grinding program, so four to five adjustments were required before contact could be made. Each adjustment took about 15 minutes, resulting in a total set-up time of 1.5 hours per tool change.

Enormous loss of time

This high expenditure of time naturally goes hand in hand with higher costs: at an average hourly rate of 100 euros per hour, this means a considerable cost burden, as we are talking about 150 tool changes per month on 10 tool grinding machines.

ZOLLER Solutions

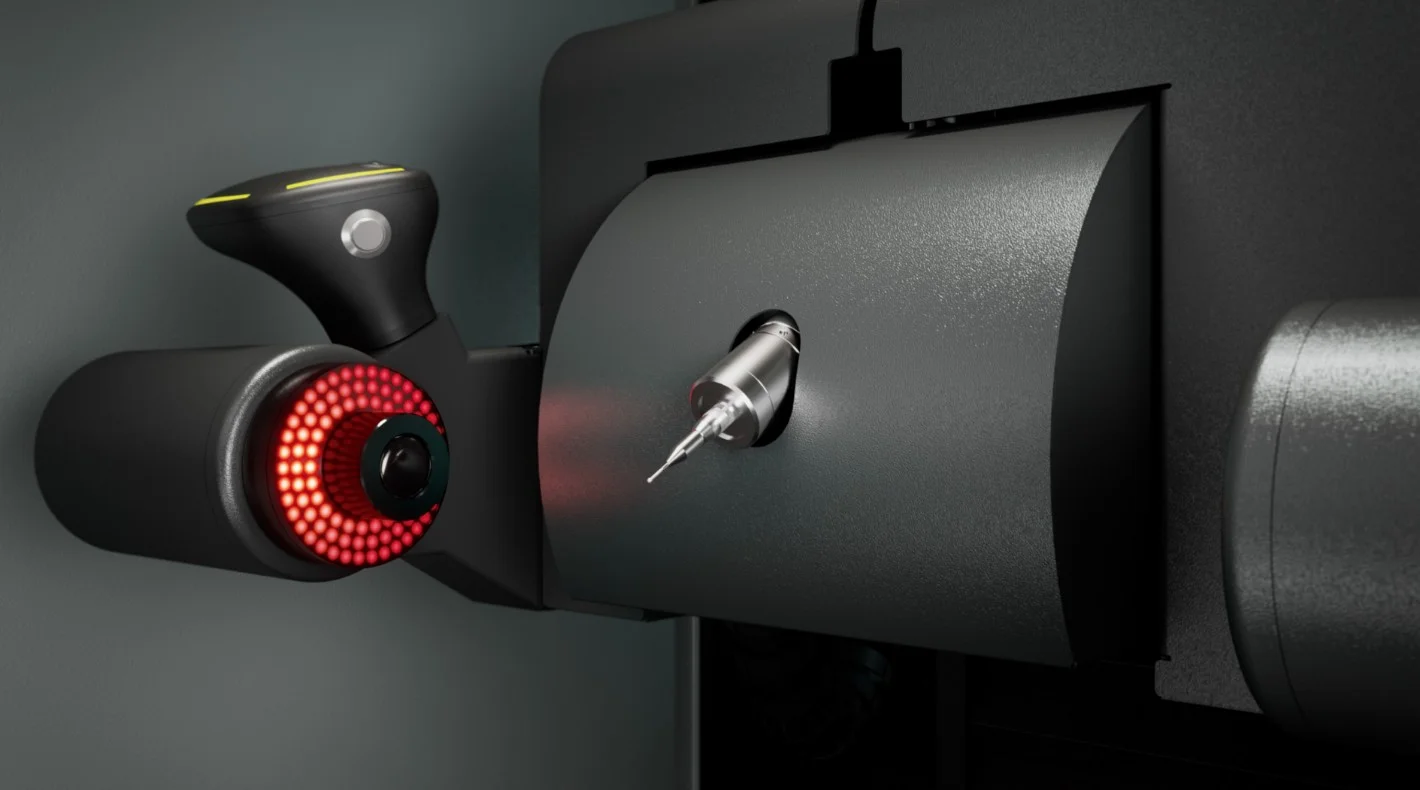

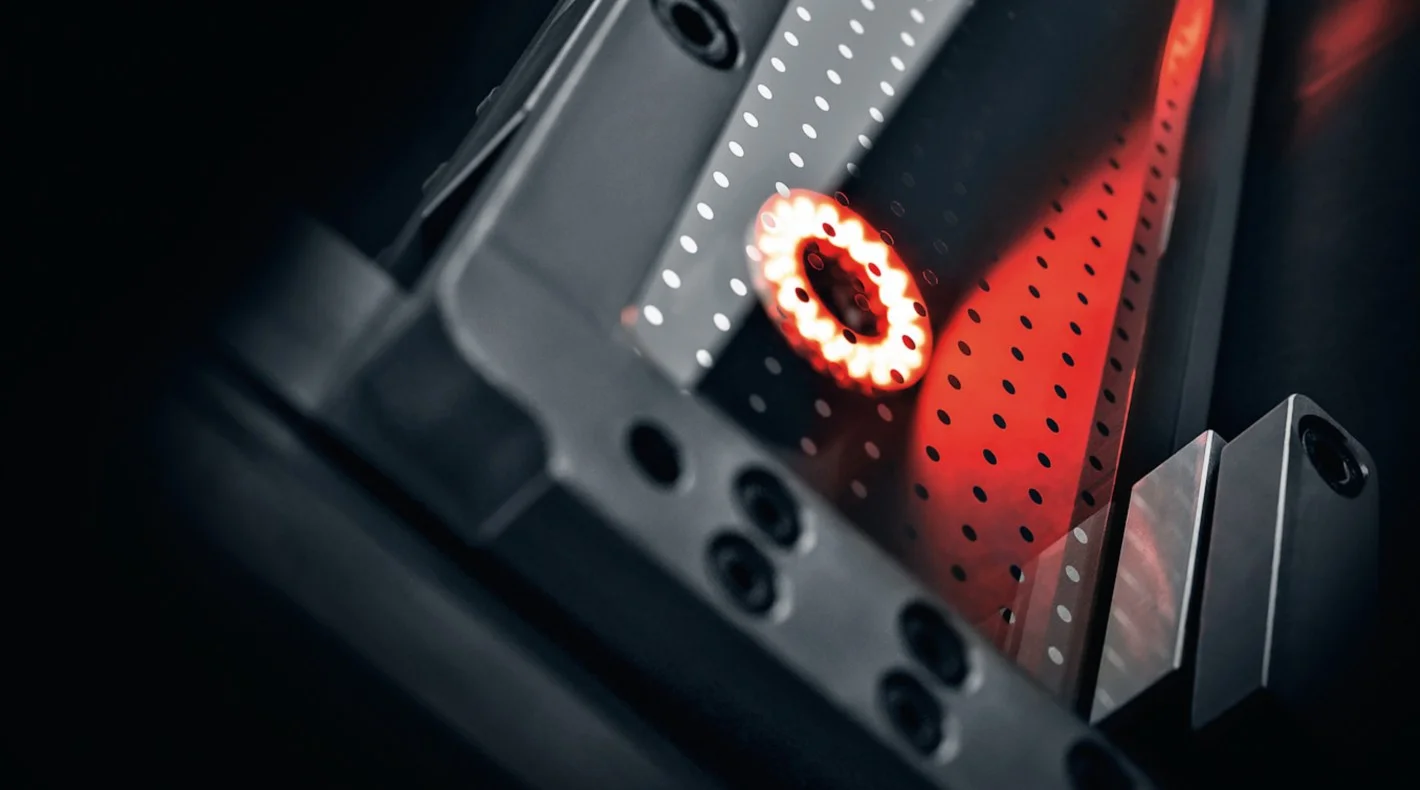

To overcome these challenges, the »genius« precision measuring machine from ZOLLER was introduced. The »genius« was used to precisely measure not only cutting tools, but also the grinding wheels used in the tool grinding machine, thereby implementing an external set-up process.

Many improvements

The introduction of the ZOLLER »genius« brought the customer remarkable benefits overall. Firstly, the precise measurement of the grinding wheel shapes and dimensions eliminated air cuts in the grinding wheels. This meant a considerable reduction in set-up time: the elimination of air cuts led to a reduction in set-up time of one hour per tool change. All in all, this means The current set-up time is 0.5 hours - compared to around 1.5 hours previously! This actually results in enormous cost savings. The ZOLLER solution led to monthly cost savings of approx. 15,000 euros, based on corresponding projections.

Result: Cost efficiency with ZOLLER »genius«

The introduction of the high-precision »genius« universal measuring machine has made a significant contribution to reducing set-up times and costs in precision tool production at our customer in the Kansai region. The high-precision measuring functions of the ZOLLER »genius« have eliminated the air cuts of the grinding wheel, resulting in greater efficiency in the manufacturing process. Looking ahead, the company plans to continue using ZOLLER »genius measurement technology« to further increase productivity and ensure consistent quality in its manufacturing processes.

-

User report »genius« 3 MB

User report »genius« 3 MB

Back to overview

Back to overview