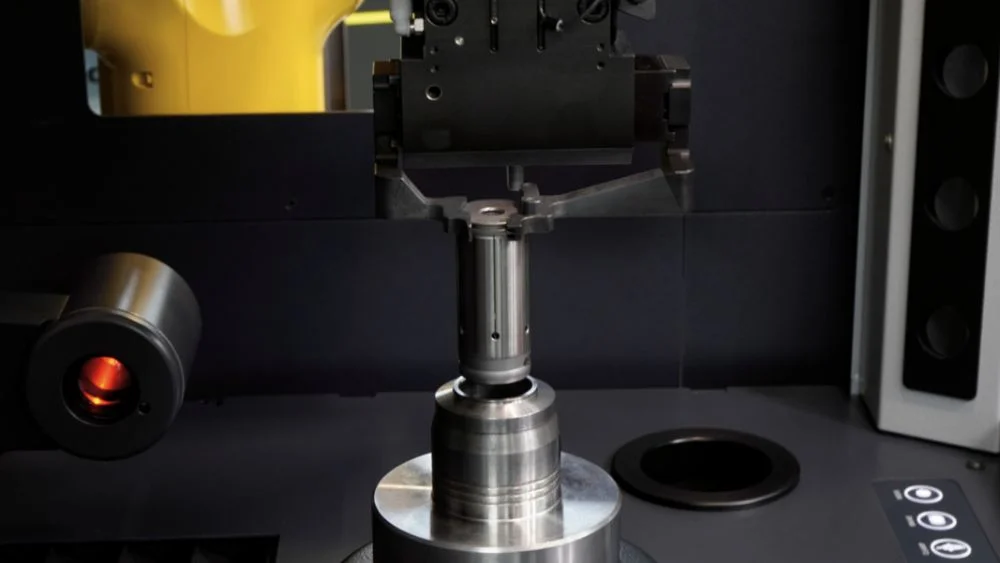

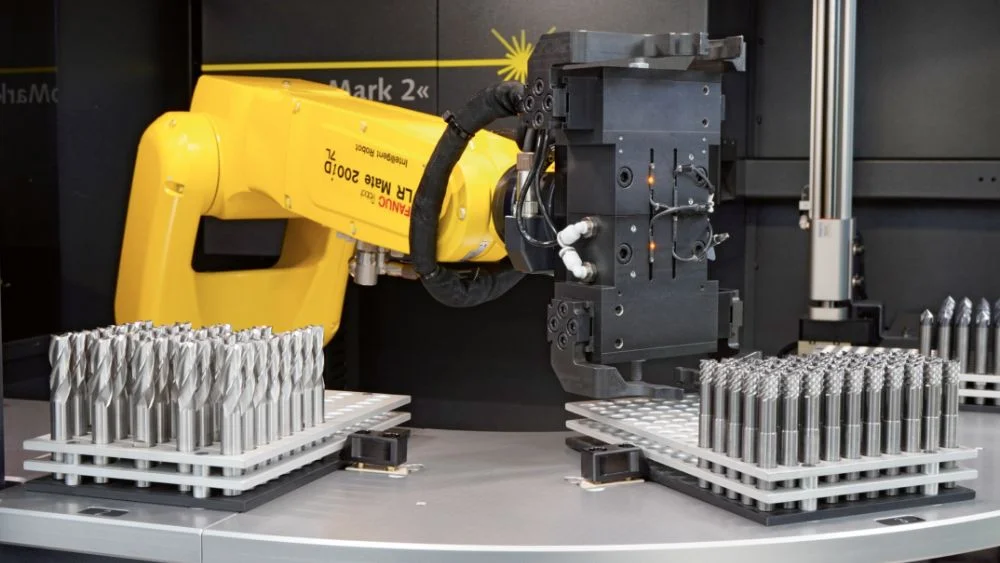

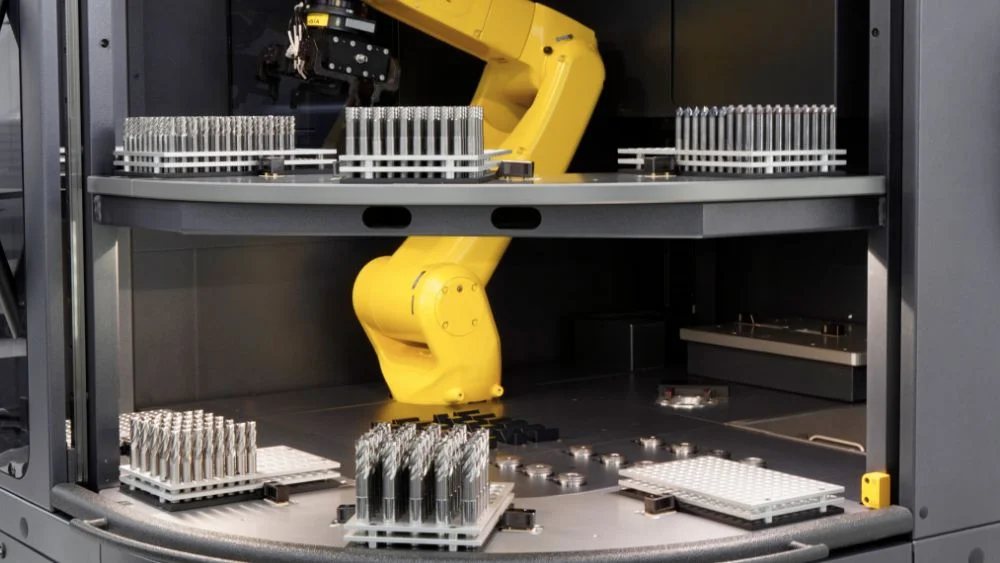

The robot integrated in the »roboSet 2« makes it possible to guarantee a high tool throughput 24/7 without an operator. The robot performs even complex and time-consuming measuring tasks independently - maximum process reliability and measuring accuracy are always guaranteed. The integrated force/torque sensor also offers you the option of reliably inserting shank tools into tight fits such as intermediate bushes.

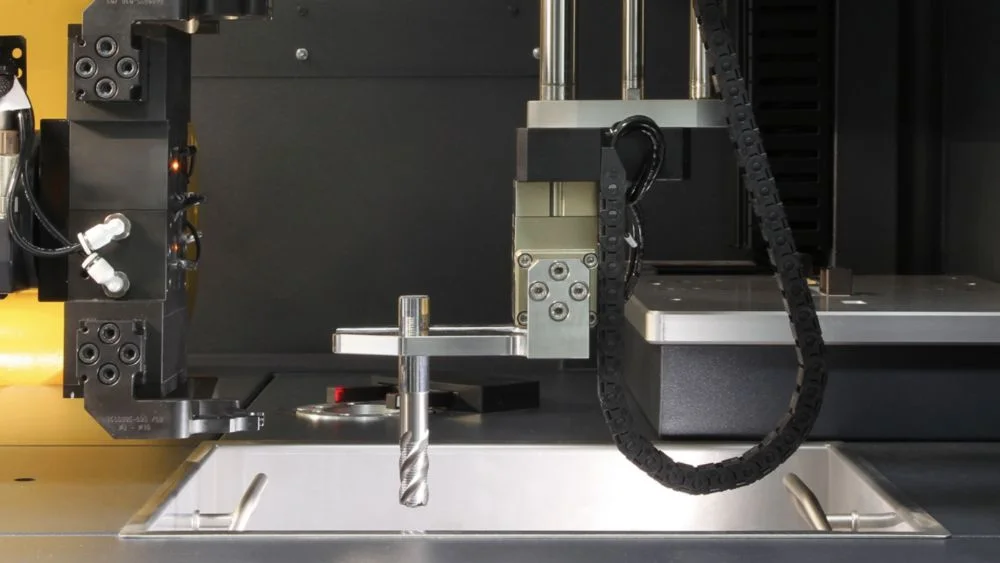

Before the »roboSet 2« automation solution can start its work process, only the loading of the tools must be defined by an operator via the pallet management in the »pilot 4.0« software. Thanks to the multi-pallet system (eight pallets as standard, nine as an option), large quantities can be processed and documented fully automatically. Overall, well-organized pallet management makes a significant contribution to process optimization, provides flexibility to handle different batch sizes and helps to move goods more efficiently and sustainably.

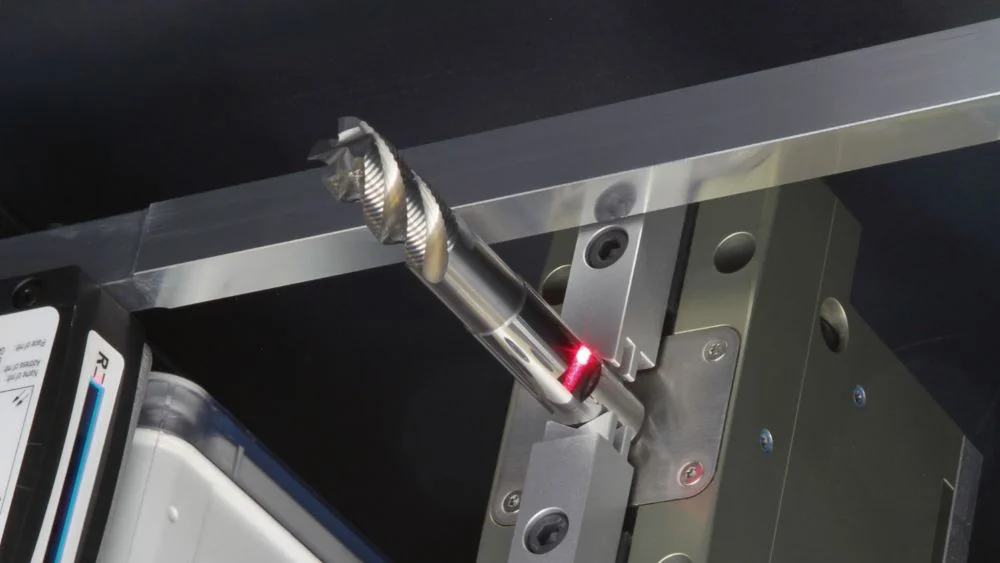

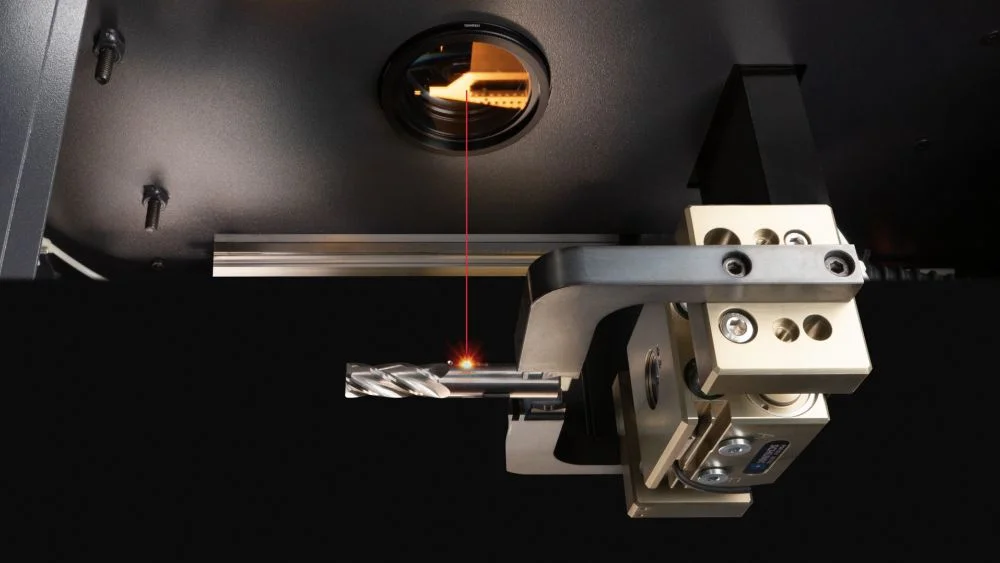

With the ZOLLER »roboMark« laser marking system, tools that have been measured within tolerance can be marked either on the circumference or the end of the shank. The marking itself is individual and offers many different setting options. QR or DataMatrix codes can also be applied without additional effort and enable traceability of the respective tool via the link to the tool database.

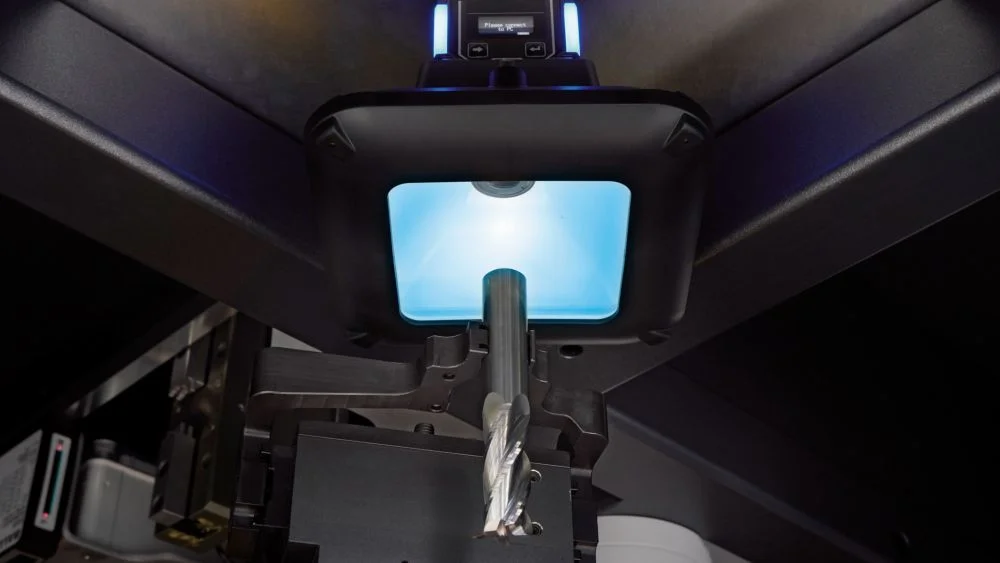

During automatic tool recognition, QR codes, DataMatrix codes, etc. are read via an integrated scanner. Thanks to the interface to ZOLLER TMS Tool Management Solutions, all information on the scanned tools is accessible and links to external workstations (e.g. to the regrinding counter) can also be implemented.