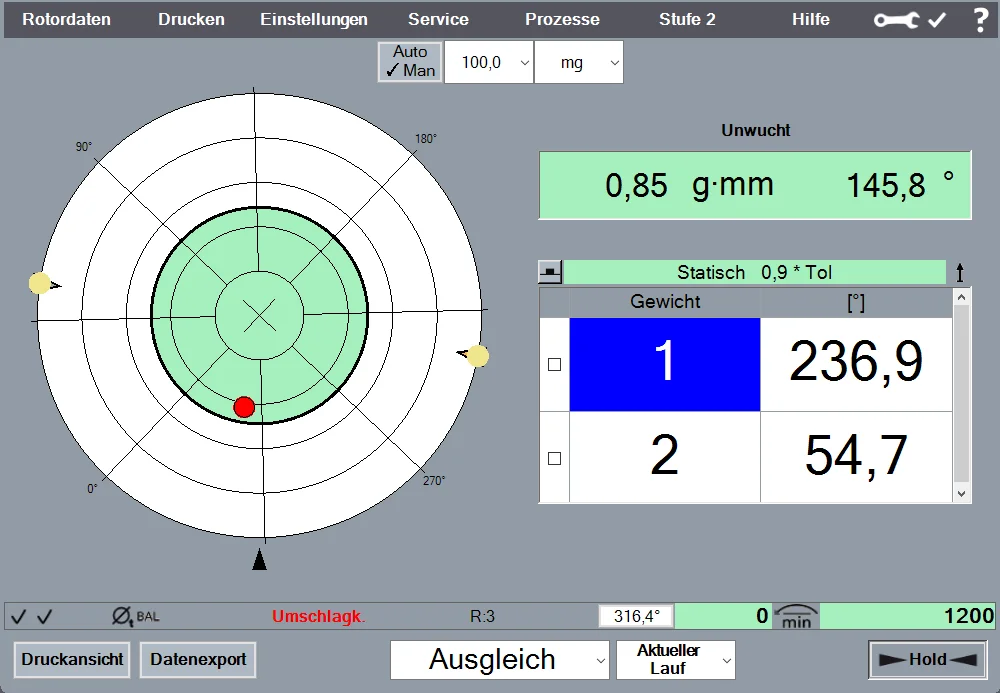

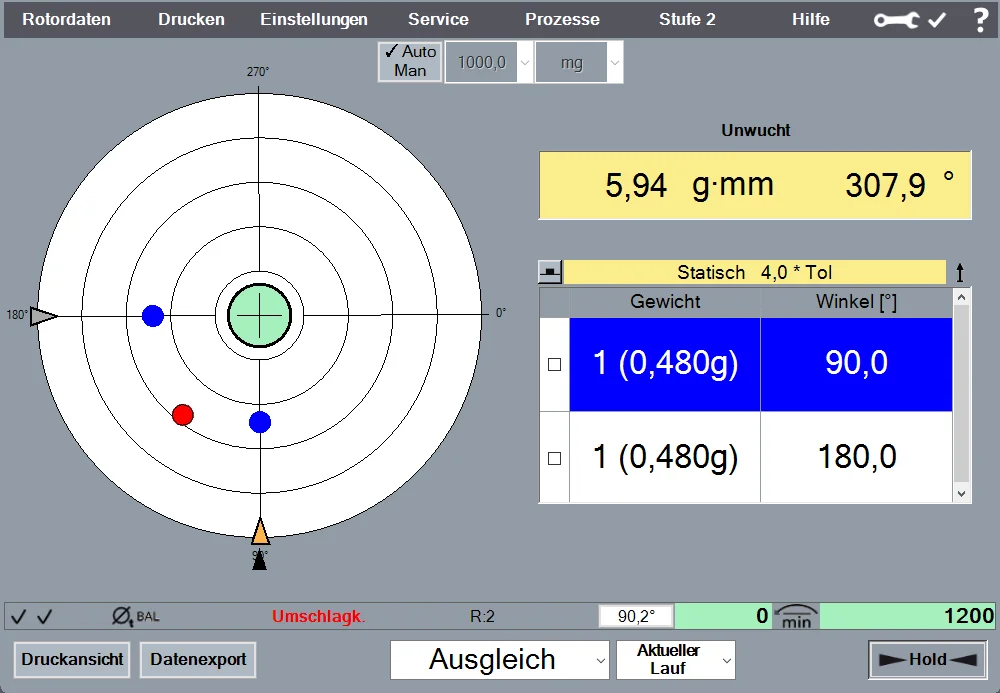

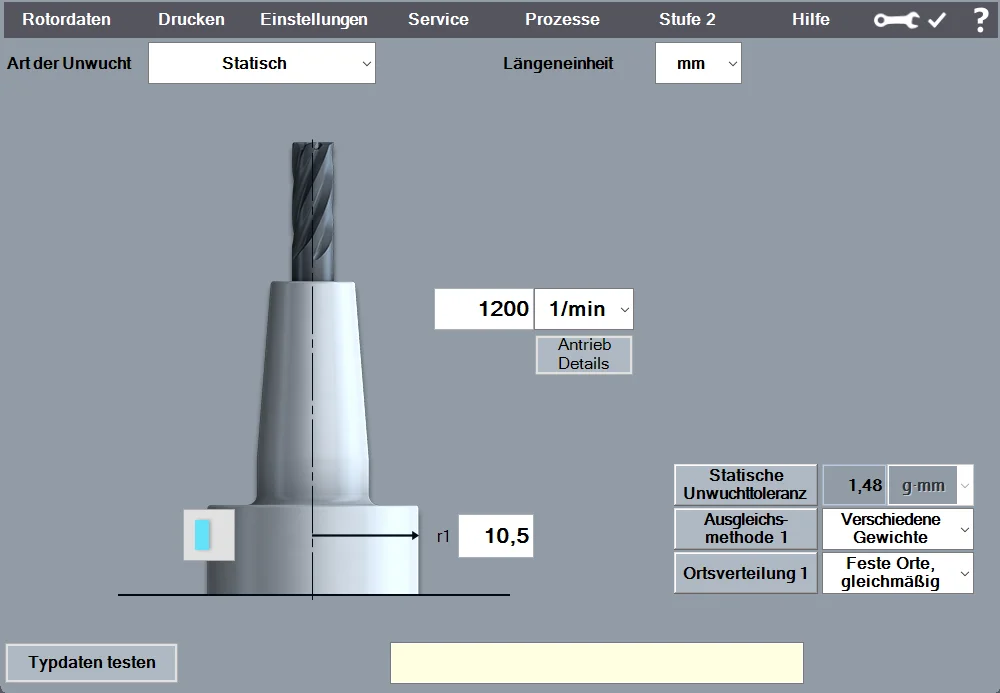

Balance correction "Various weights "

Correction of unbalance by attaching or removing weights (e.g. balancing screws). Incl. presetting option for existing weight sets.

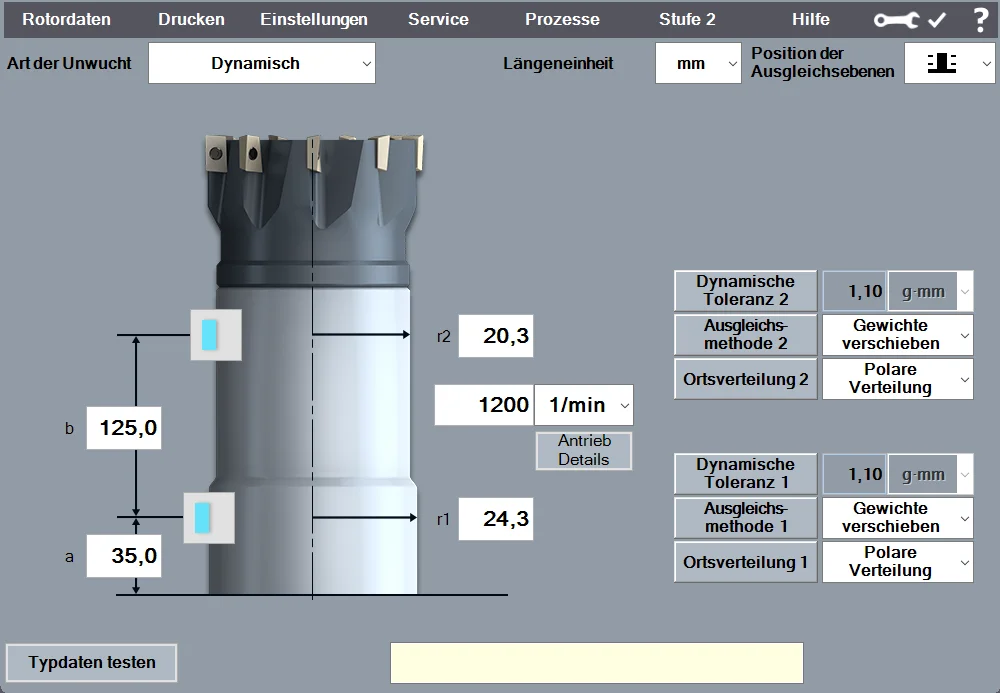

Balance correction "Shift weights"

Correction of unbalance by turning balancing rings or sliding blocks.

Balance correction "Drilling radial"

Correction of unbalance by radial drilling. Automatic calculation of the number, angular position and depth of the holes.

Balancing correction "Milling"

Correction of unbalance by radial, tangential or axial milling.

Axial drilling" balance correction

Correction of unbalance by axial drilling. Automatic calculation of the number, angular position and depth of the holes.