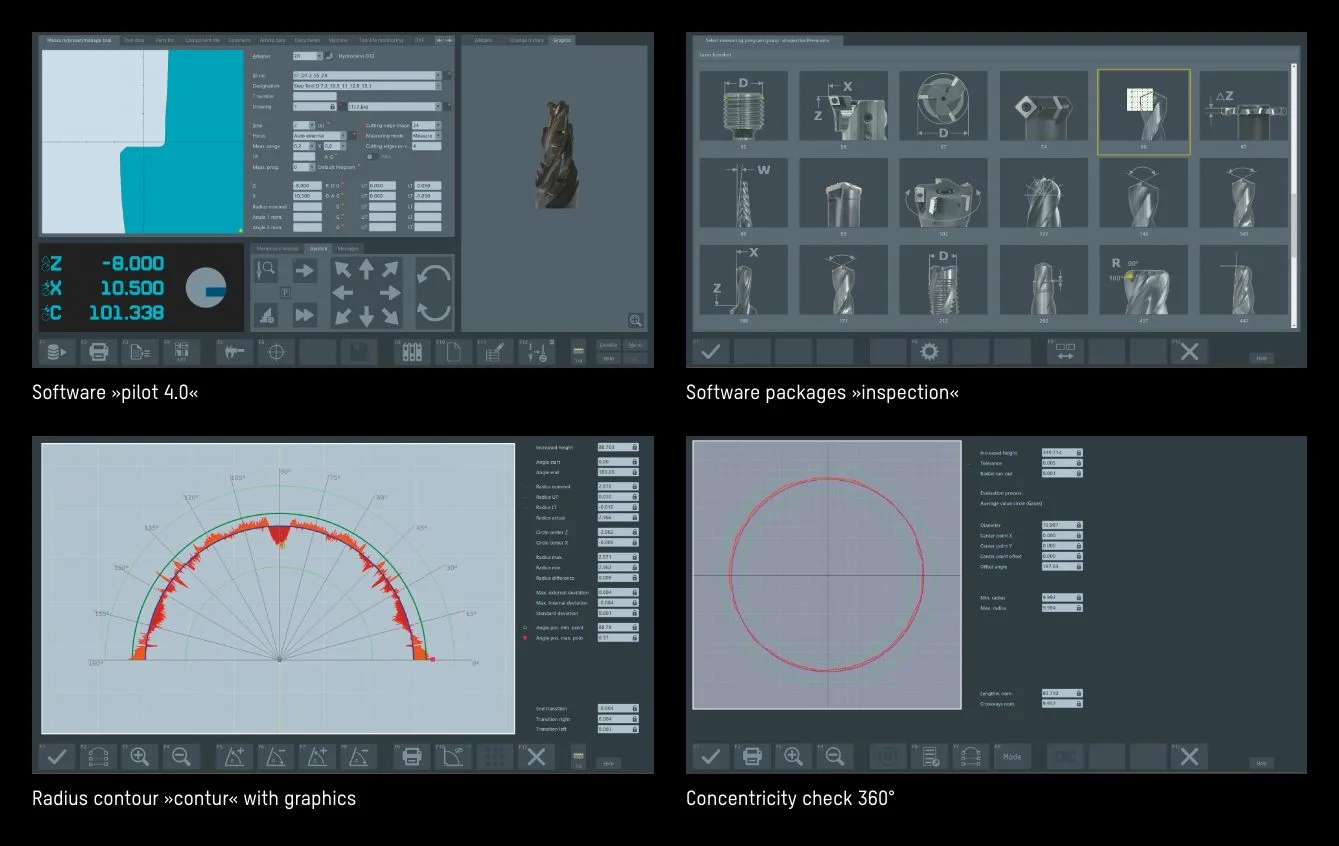

»pilot 4.0« has established itself as a powerful and comprehensive software solution for all ZOLLER presetting, measuring and inspection machines. The intuitive, graphical user interface guides the user quickly and reliably to precise measurement results. Thanks to »pilot 4.0«, even complex measuring tasks can be completed at the first attempt. At the same time, the software is so comprehensive in its functionality that there is a solution for every requirement. It is not for nothing that »pilot« is considered the world's unrivaled benchmark for measuring, testing and managing cutting tools.

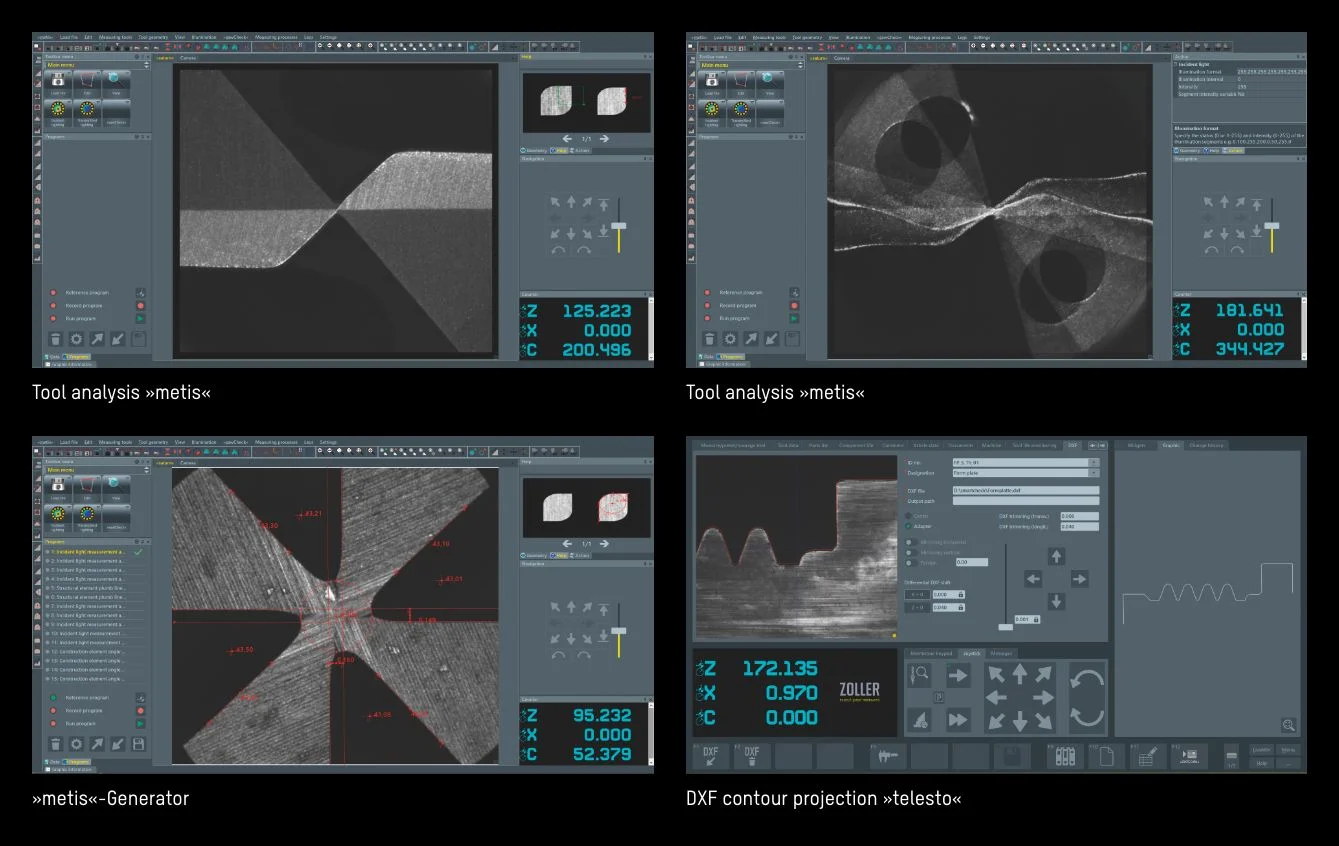

Equipped with a swiveling incident light camera, the ZOLLER »smileCheck« and »smartCheck« device series is ideal for tool inspection. Tool parameters, geometry data and cutting edge contours are recorded both radially and axially, allowing tool analyses to be carried out universally, quickly and easily.

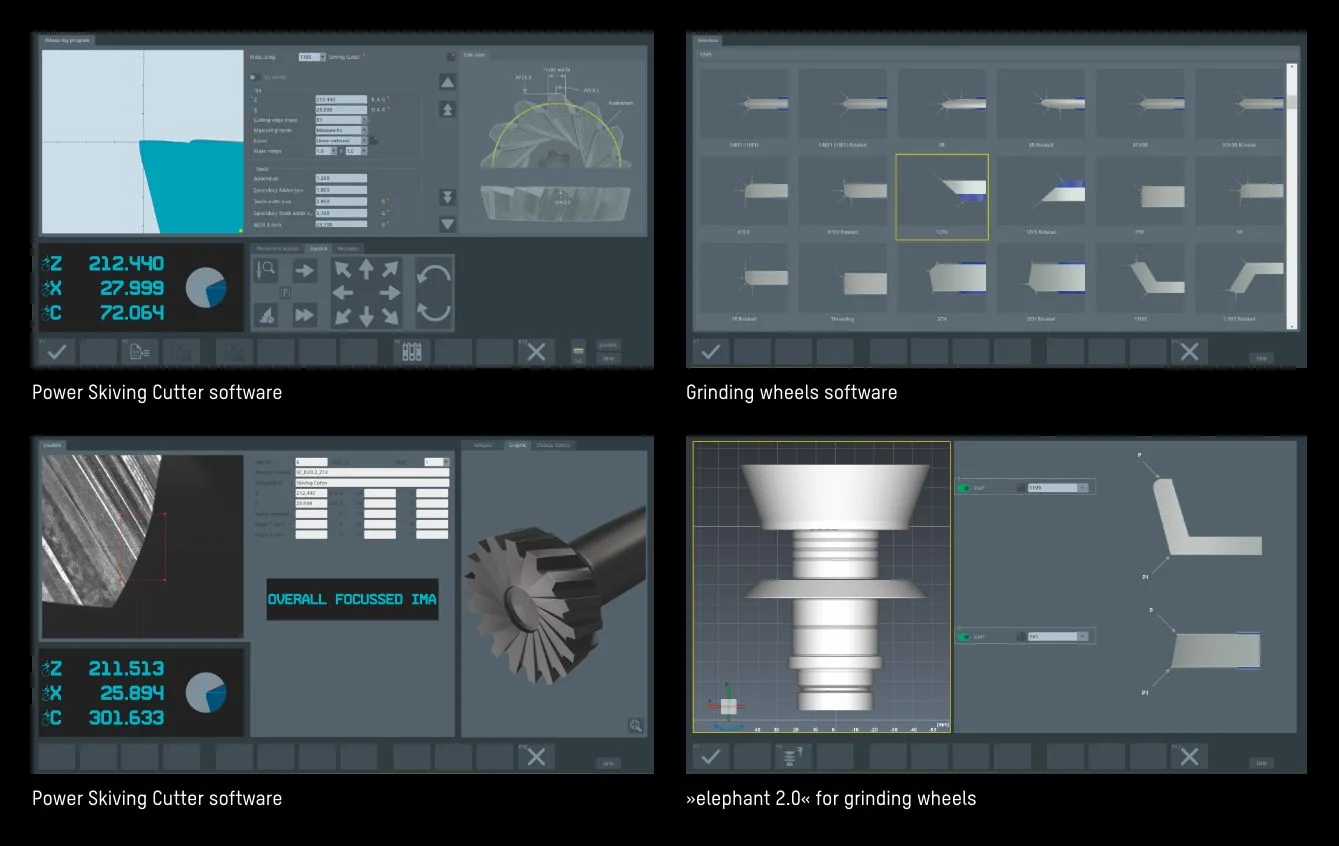

Precision across the board - »pilot 4.0« also offers innovative solutions for special applications and is continuously being developed in-house by ZOLLER with a large development capacity in order to meet the requirements of new tool technologies and to competently implement customer requests while making existing processes even simpler and more efficient. For example, the important preparation of grinding wheels for new orders. ZOLLER offers the perfect end-to-end solution for short set-up and throughput times: From administration, storage, assembly to measurement and transfer of measurement data to your grinding machine.

Pioneering efficiency for your grinding shop

The greatest potential for efficiency lies outside the grinding machine: ZOLLER Solutions stand for your future - we make you more successful. Because those who manufacture faster and more efficiently operate more economically in order to be able to invest in the future. If economic progress is your goal, then ZOLLER is your partner.

Logging and networking your data

Contour correction

Contour correction for forming tools

Contour correction for forming tools - target/actual comparison of the scanned contour with the target contour in DXF format. The »coCon« software inverts the deviations and generates a contour correction that is transferred to the machine as a new DXF file.

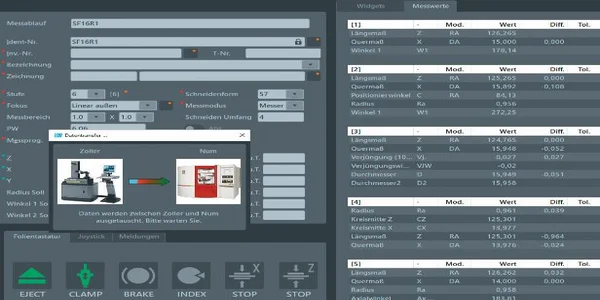

Interfaces

Interfaces

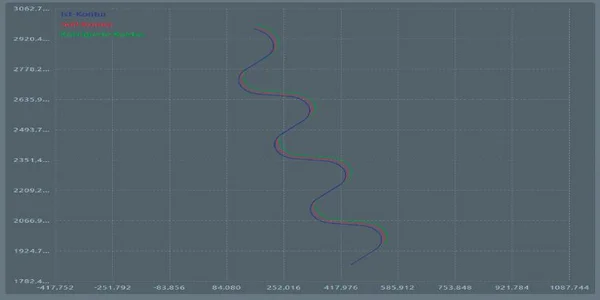

Interfaces - the inspection and measuring machine receives a measurement data file from the programming system or the grinding machine and automatically generates the measurement sequence. The measured actual tool data is transferred from the ZOLLER inspection and measuring machine to the programming system or to the machine control, where the NC program is optimized for series production.