»smileCheck« - Compact basic model

One-hand operating handle »eQ«

Ergonomic one-hand operating handle »eQ«

Ergonomic one-hand operating handle »eQ« (ergonomic & quick) - to easily move the optics carrier to the correct position in the Z and X axes. The button with the Solutions symbol can be individually configured with additional practical functions, making operation even easier and more convenient.

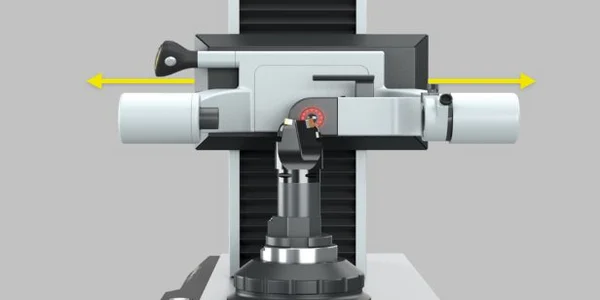

Z-, X-axis

Z-, X-axis manual/CNC

Z-, X-axis manual/CNC - the high-precision and smooth-running linear axes are used for quick and fine positioning of the measuring optics to the tool cutting edge. Whether manually for spot checks using the »eQ« single-handed operating handle or CNC-controlled for fully automatic processes, they enable reliable, fast and convenient measurement.

Manual fine adjustment - the alternative to CNC control. The ergonomic handwheels for additional manual fine adjustment of the Z and X axes are particularly suitable for the tool inspection module.

Y-axis

Y-axis

Y-axis - the optional, CNC-controlled linear axis for measuring off-center cutting edges on turning or multifunctional tools.

Storage shelf

Practical storage shelf

Practical storage shelf - holds attachment holders, adapters, tools and intermediate sockets.

Incident light camera

Tool inspection with manually swiveling incident light camera

Tool inspection with manually swiveling incident light camera - for radial and axial inspection and measuring tasks. The integrated LED ring light with adjustable light intensity ensures optimum illumination of the surface. The clamping and locking device as well as the swivel range of -30° to 90° ensure an ideal perspective for the respective measuring point.

Software »pilot 4.0«

»pilot 4.0« software

»pilot 4.0« software - is self-explanatory, clear and enables the operator to take reliable measurements. It offers a uniform user interface on all ZOLLER systems - right up to ZOLLER TMS Tool Management Solutions. The individual structure of the software allows customer-specific adaptations to be implemented quickly.

Integrated operating unit - offers health-friendly and comfortable working. The 24" TFT color monitor can be individually adapted to the needs of each operator: The height, swivel and tilt angle can be flexibly adjusted.

High-precision spindle

High-precision spindle SK 50

High-precision spindle SK 50 - for holding tools or adapters with interface SK 50. Adapters for reduction allow simple and precise clamping of almost any tool holding system. The optional CNC drive with autofocus and precise angle measuring system offers automatic focusing of the tool cutting edge and recording of the cutting contour.

Label printer

Label printer

Label printer - for printing the measurement results or DataMatrix codes on adhesive paper or thermal labels.