ZOLLER turret table

Sophisticated and comfortable

Not all turret tables are the same! ZOLLER turret tables are extremely stable, easy to handle and work with absolute precision.

ZOLLER turret tables do not bend, even with long projecting and heavy tools. They rotate easily into the desired position without any stops. The pneumatic and electric elements are docked automatically. Lifting and lowering is power-operated at the touch of a button and lowering is electronically monitored and visually displayed. Which tool holders are fitted to the ZOLLER turret tables depends entirely on your requirements. You can choose between 4-, 6-, 8- and 12-fold indexing and a variety of possible tool holders.

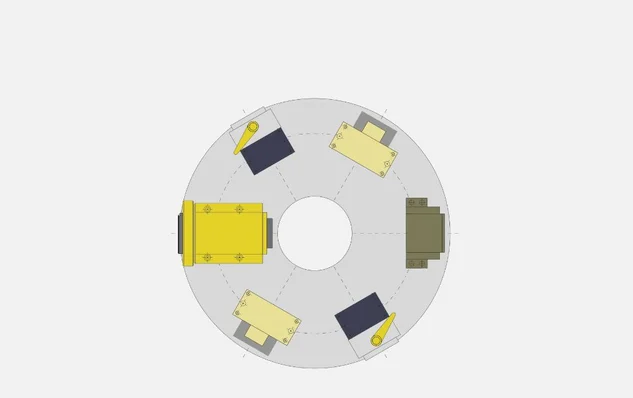

Fitting D 745 - 6-fold pitch

For different tool holders. By turning the turret table, the user always has the correct tool holder in the measuring range.

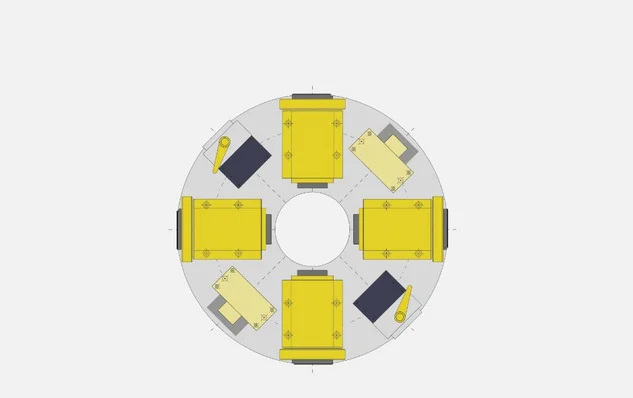

Fitting D 745 - 8-fold pitch

For four universal holders HGH-UZ, two basic holders GA-PP and two basic holders GA. The number of adapters and attachment holders that can be used is virtually unlimited.

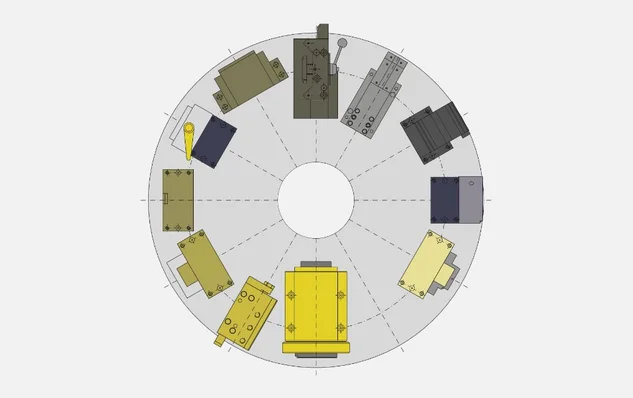

Fitting D 900 - 12-fold pitch

Universal holder HGH-UZ for rotating and stationary

tools - special tool holders for Göltenbodt

tool holders for Göltenbodt, Schütte, Traub, Index and others can also be fitted.

Docking and support

The intelligent docking system for electrical and pneumatic

pneumatic elements enables unlimited

turret table rotation.

Automatic zero point selection

With »hyperion 500/700«, automatic zero point selection is possible via the turret table positioning (optional).

Foot switch

For clamping and releasing the tools in the tool holder (optional).

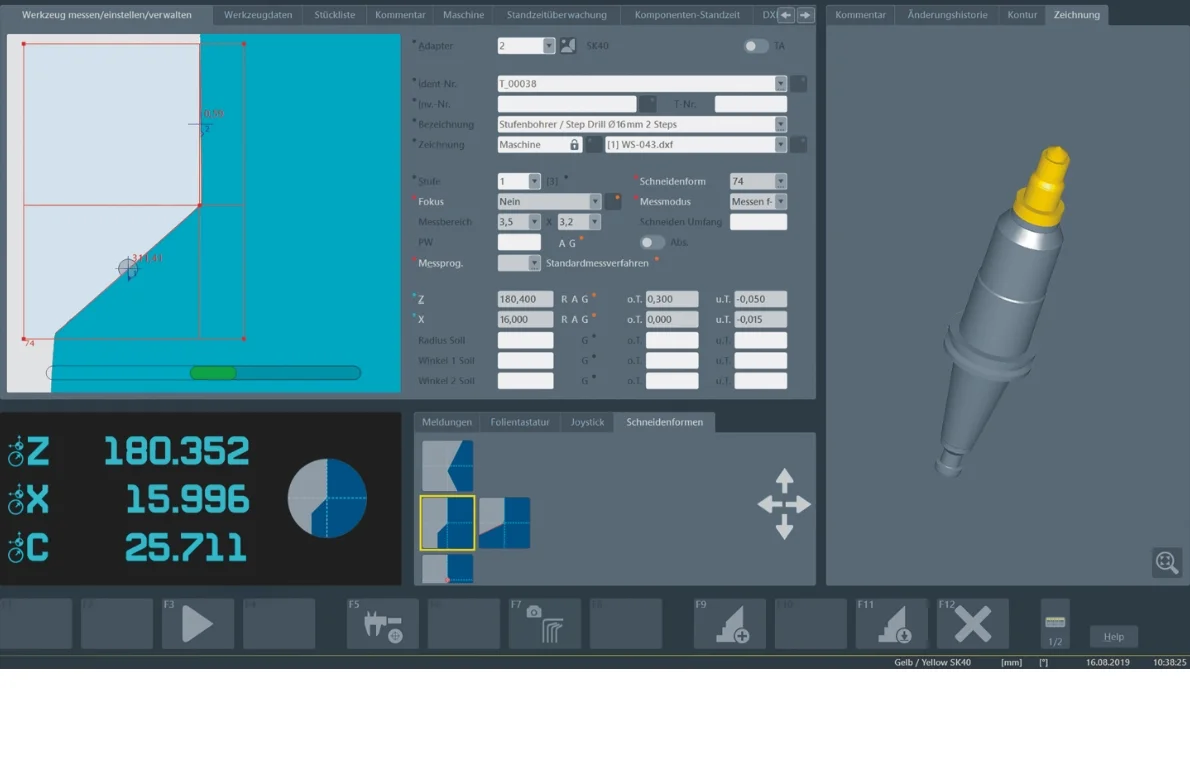

»pilot 4.0« is the extensive and comprehensive software solution for all ZOLLER presetting and measuring machines. The intuitive graphical user interface guides users quickly and reliably to precise measurement results. This makes »pilot 4.0« so easy to use that even complex measuring tasks can be completed immediately. At the same time, the software is so comprehensive in its functionality that there is a solution for every requirement. It is not for nothing that »pilot 4.0« is considered the world's unrivaled benchmark for tool setting, measurement and testing.

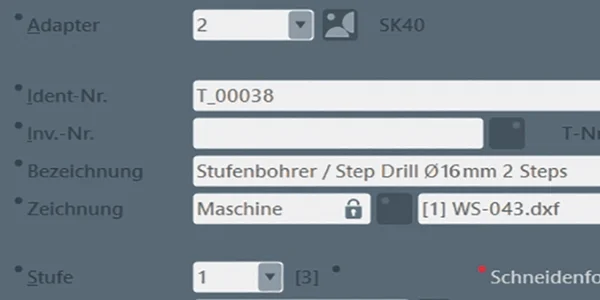

Tool-specific information

Adapter management

- Tool designation for individual identification

- Target values with tolerances

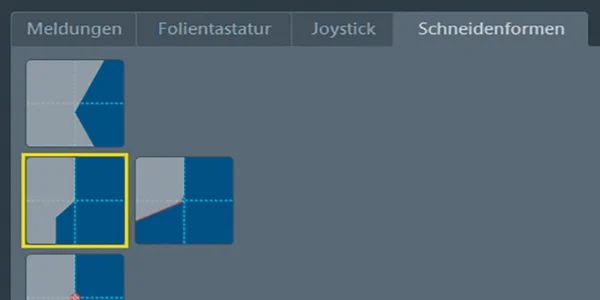

Cutting edge shapes

Automatically recognized cutting edge shapes

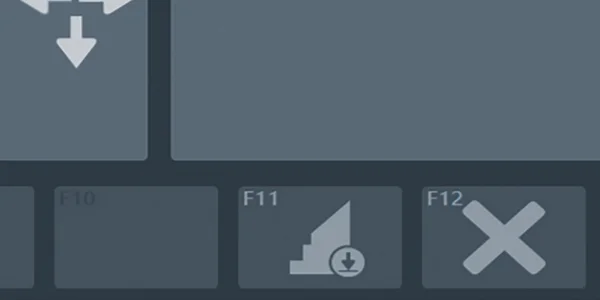

Function buttons

With self-explanatory icons

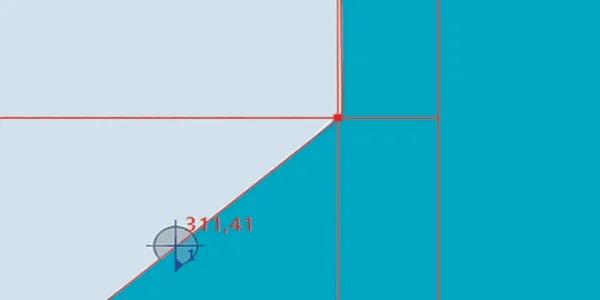

Current camera image of the cutting edge

- Dynamic crosshairs

- Angle indication with selectable reference axis

Current position information

- Current position information of the axes

- Currently active cutting edge shape

- Tool designation for individual identification

- Target values with tolerances

Automatically recognized cutting edge shapes

With self-explanatory icons

- Dynamic crosshairs

- Angle indication with selectable reference axis

- Current position information of the axes

- Currently active cutting edge shape