ZOLLER offers two types of cooling systems: A non-contact cooling system with air cooling and cooling adapters. Depending on the tool diameter, the cooling time with cooling adapters is 60 to 120 seconds. With »Zstream« air cooling, the process is called conditioning, in which the entire tool holder is cooled from the nose to the flange. The conditioning time here depends on the diameter of the holder and is 3 to 5 minutes.

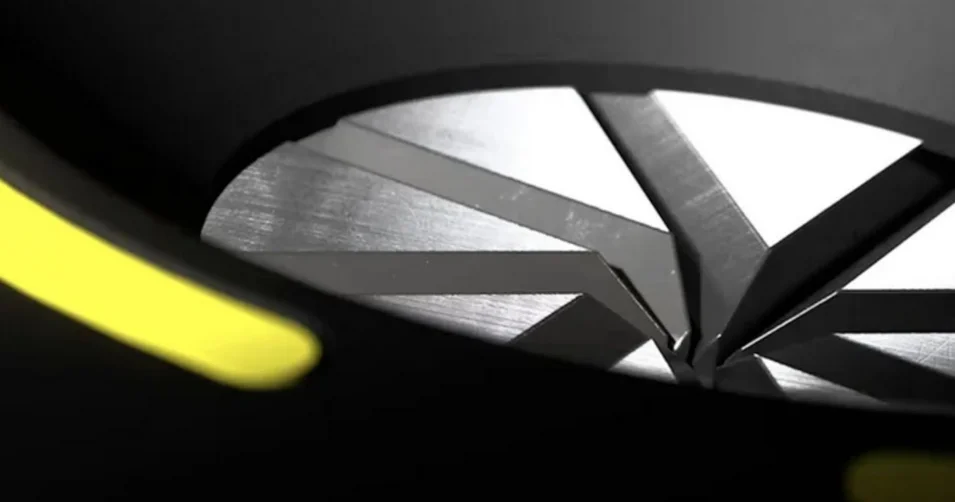

The concept is simple. Each shrink tool holder is manufactured with an internal diameter that is slightly smaller than the shank diameter of the cutting tool. Using an induction device, the nose area of the tool holder is quickly heated to increase the internal diameter. At this point, the cutting tool can be inserted into the tool holder. The tool holder is then cooled and the diameter shrinks, exerting a force on the shank of the cutting tool to hold it precisely in position.

When tool holders are shrunk without direct contact, the tool holder system is called non-contact cooling. This is done, for example, with the help of cooling adapters or air cooling.

If the tool holders are cooled with a liquid after heating, this process is called quenching. The service life of the holder is reduced and the holder rusts if the tool holder continues to be used with liquids directly on it. The cooling liquid becomes dirty after a short time and must be replaced, otherwise it collapses, smells strongly and contains harmful ingredients that are dangerous to human skin.