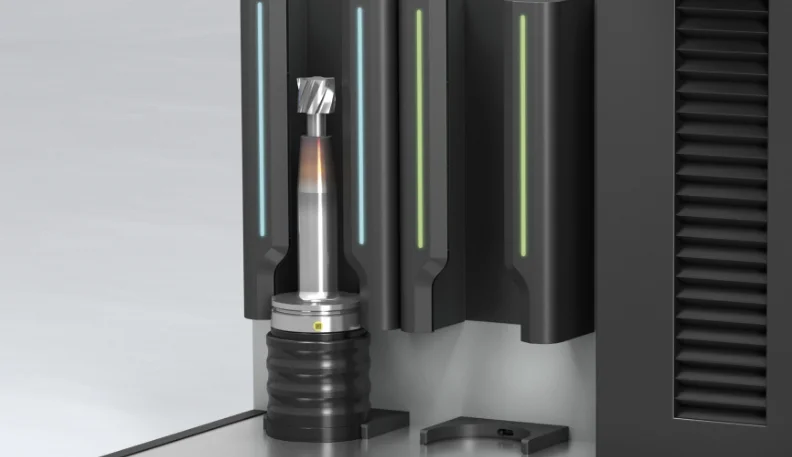

The fume extraction system reliably removes fumes from the operator's working area. The established and patented fume extraction system above the induction coil has been extended to include an integrated extraction system inside the coil housing. The fumes are therefore extracted directly where they are produced. The filter unit has a safe place in the under-table.

The »zStream« air cooling system from ZOLLER gives you maximum flexibility and protection when cooling your shrink fit chucks, regardless of their contour or diameter. In addition, your shrink fit tools are cooled evenly and safely over their entire length - without the risk of damage. »zStream« is also ideal for cooling stepped tools. »powerShrink« is available with two or three separate cooling stations* for parallel, effective use.

*Two cooling slots for »powerShrink 400«, three cooling slots for »powerShrink 600«

The »pilot« software scan function in combination with the hand scanner enables reliable selection of the appropriate shrink fit parameter by scanning the holder number on the shrink fit holder. Regardless of the manufacturer, all shrink fit chucks with DataMatrix code (e.g. ZOLLER »idLabel«, ZOLLER »idChip«) are supported.

In the »pilot« software, each heating process can be counted for each shrink fit chuck. In addition, a warning and wear limit can be stored in relation to the permitted heating processes.

As an alternative to installation on a workbench, the »powerShrink 400« can be positioned on a set-up table with an ergonomically optimized working height, which provides a tidy space for the cooler and fume extraction system. The set-up table is optionally available with sturdy castors and an ergonomic handle to enable variable positioning of the »powerShrink 400«.

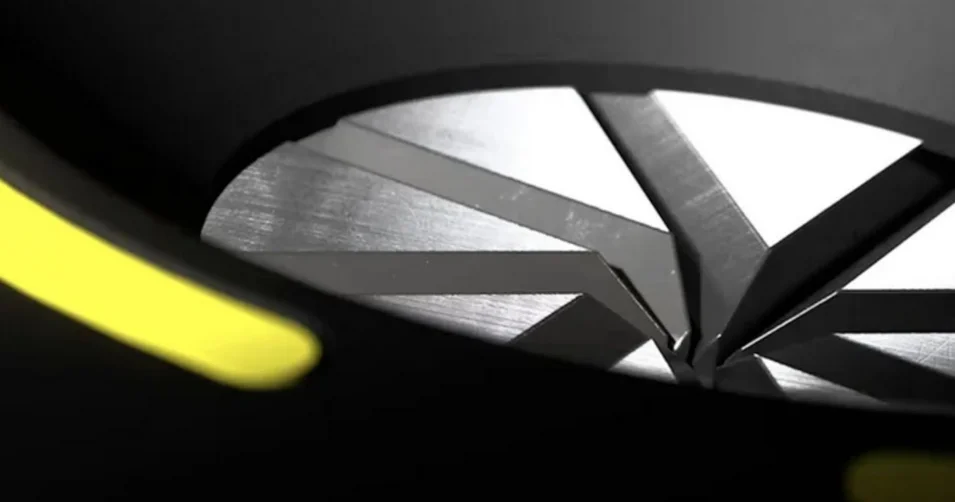

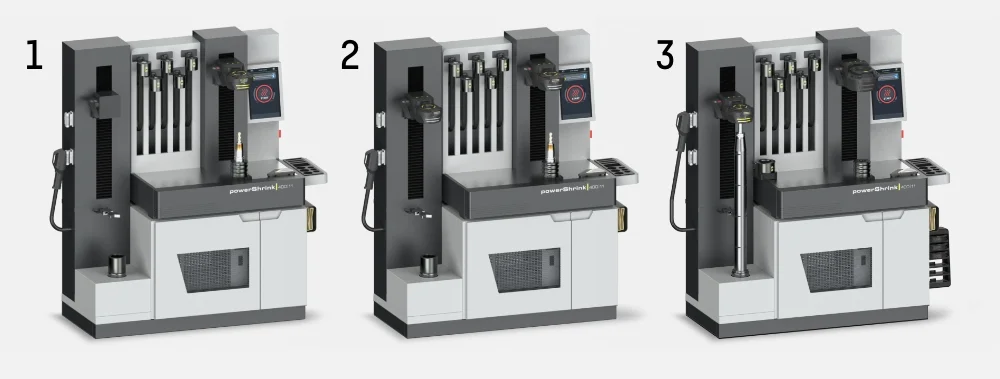

There are 3 basic configurations for the induction coils to choose from:

1. combination of any 14 kVA induction coil with quick-change interface, changing the induction coil from one induction coil axis to the other depending on the shrink chuck length

2. combination of any 2 14 kVA induction coils without »shrinkbyLight« and without quick-change interface

3. combination of any 14 kVA induction coil with a 22 kVA induction coil with quick-change interface

Storage board for mounting rings and special cooling adapters

The storage board provides space for storing four mounting rings and six special cooling adapters size I or three special cooling adapters size I and size II.

Tool tray

For storing socket tools at the shrinking workstation. The position of the tray can be freely selected by the operator.

Shelffor cleaning brushes

A shelf with all brush diameters is available for storing cleaning brushes, which can be attached to the device in any position using magnets. The brushes for cleaning the mounting hole of shrink fit chucks are also available from ZOLLER - for shaft diameters D3 mm to D32 mm, optionally made of brass or plastic.

Split shielding discs with tray

An optional set of shielding discs (5 pieces) in a split design including the corresponding disc tray can be ordered for shrink-fitting offset tools.

Device equipment

| Membrane keypad for selecting the diameter to be shrunk |

| 12.5-inch touch monitor with ZOLLER »pilot«operating software |

| Stable lower table |

| Set-up table with castors for flexible positioning in production |

| Workbench version for compact installation on your own furniture |

| Spool axis with pneumatic release of the axis clamp |

Hardware options & accessories

| Length adjustment »eQset« |

| Hand scanner |

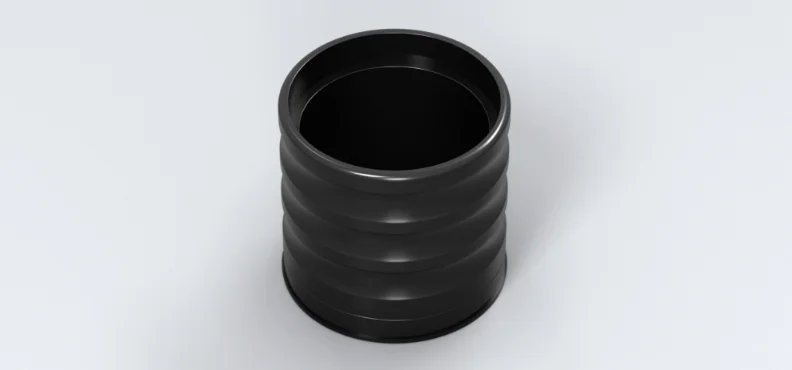

| Mounting cup |

| Mounting rings SK, HSK, polygonal shaft cone, others on request |

| Special cooling adapter |

| Storage board for mounting rings and special cooling adapters |

| Tool tray |

| Tray for cleaning brushes |

| Five split shielding disks with disk storage |

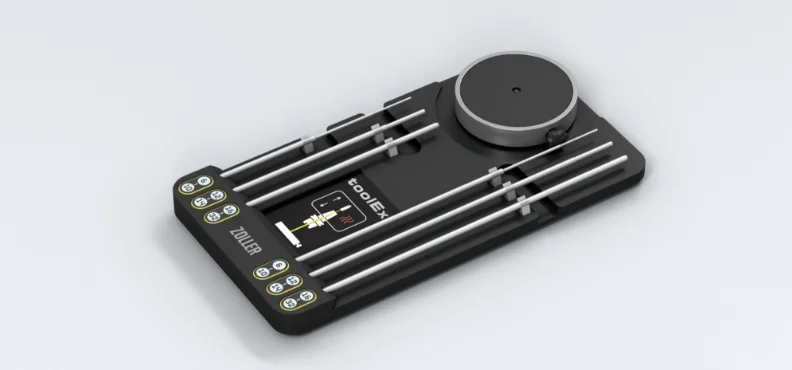

| Shrinking device »toolEx« |

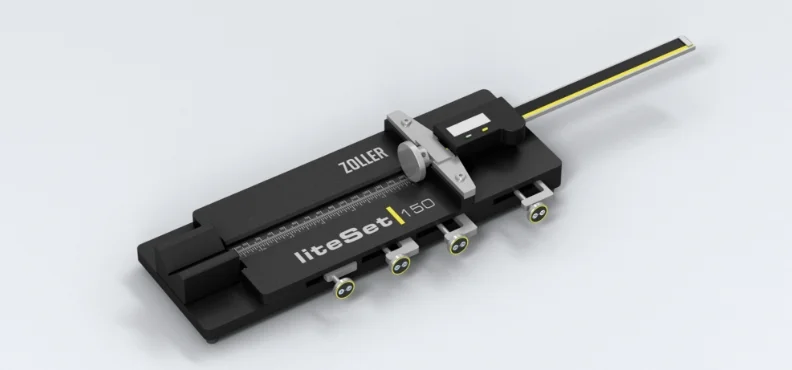

| Position adjustment »liteSet« |