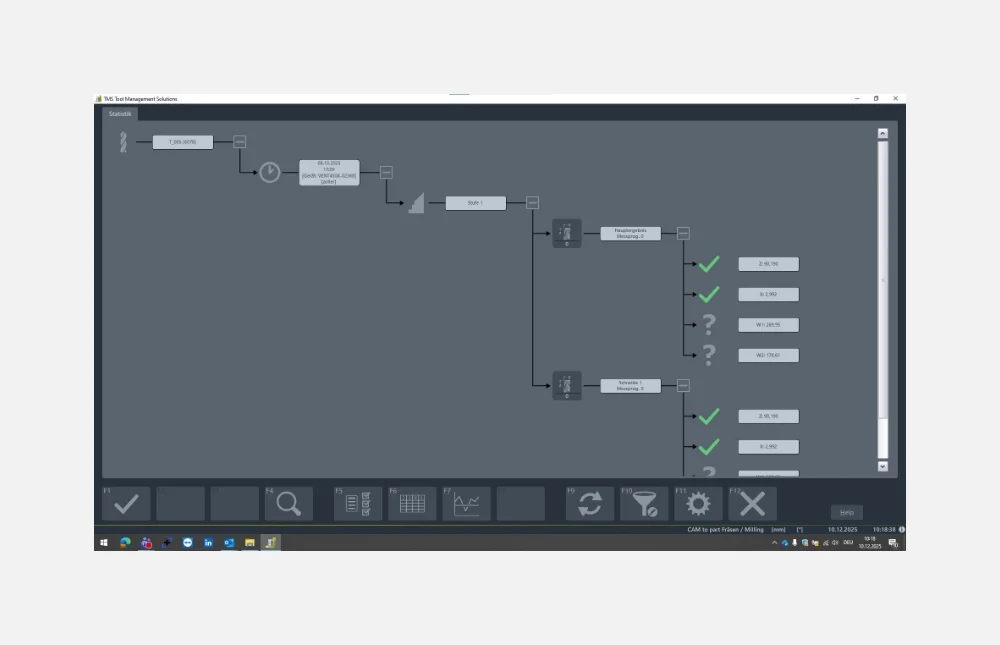

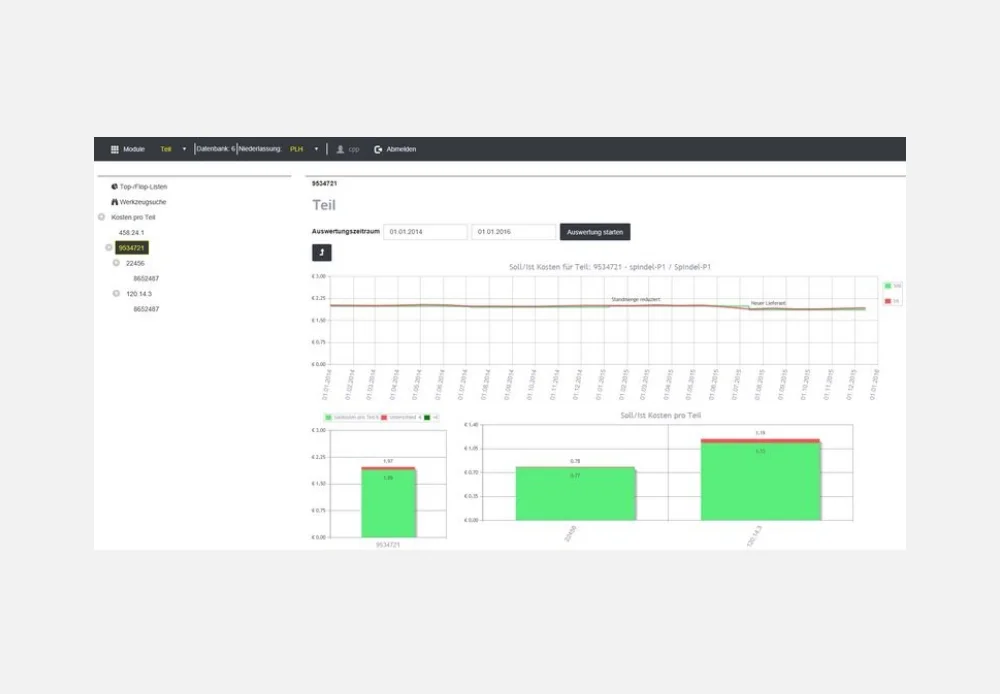

The GOLD package from ZOLLER maximizes the efficiency of your tool data management. You gain full cost control and transparency of your tool management across the process chain. With statistics on individual tools and orders, you control your costs, evaluate them and thus always make the right decisions.

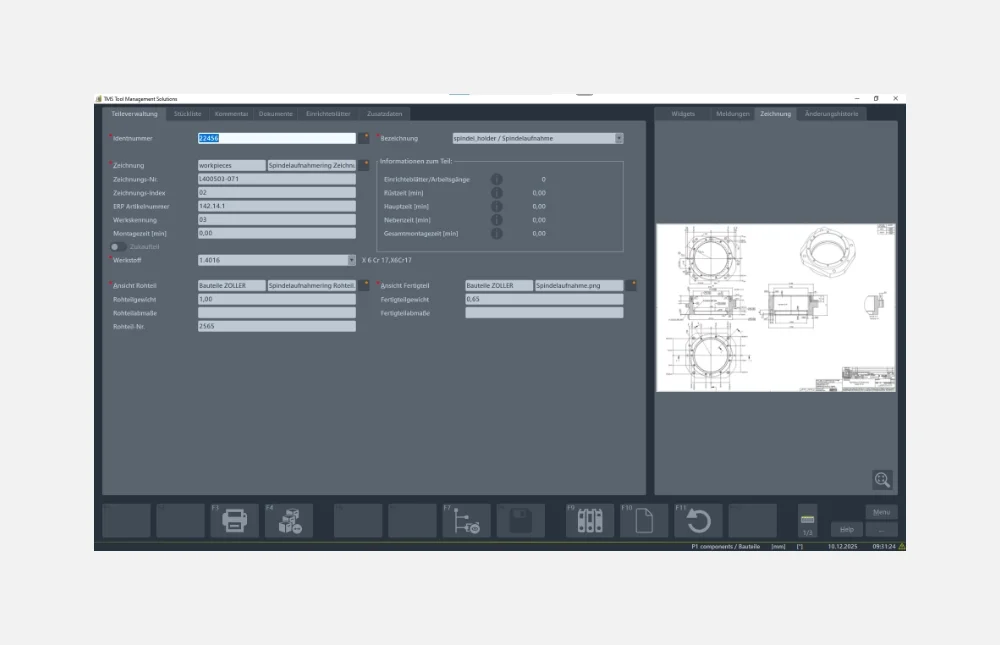

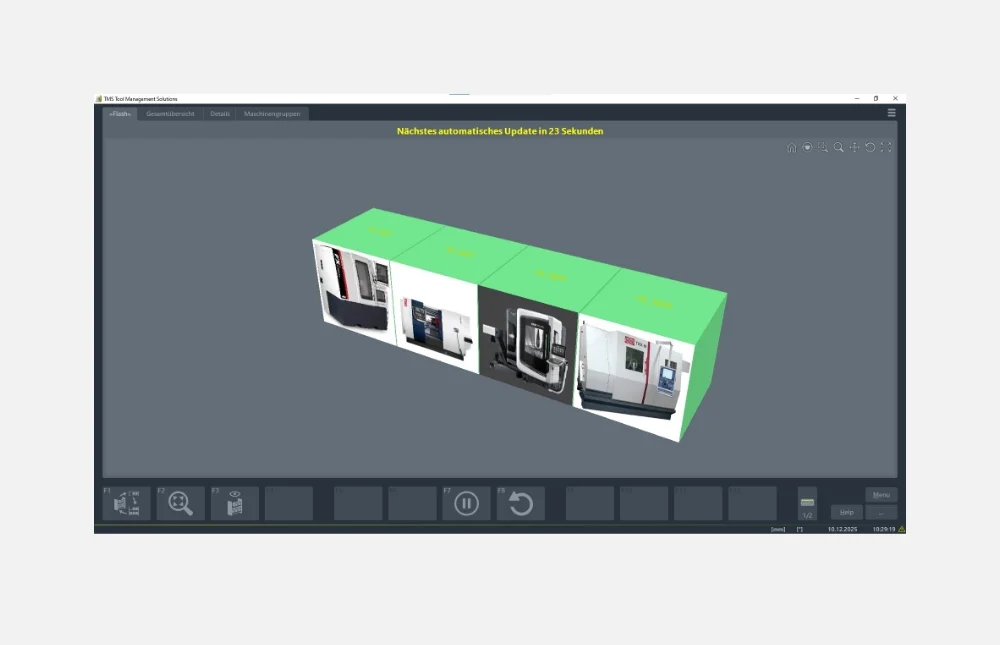

- Seamless organization of tool data

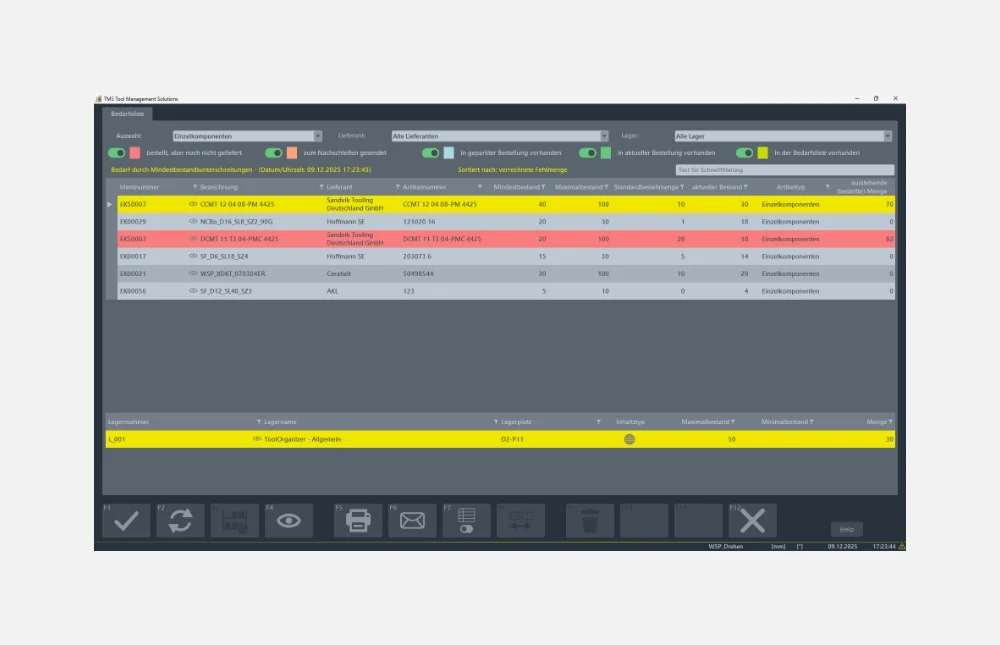

- Full cost control, transparency and efficiency

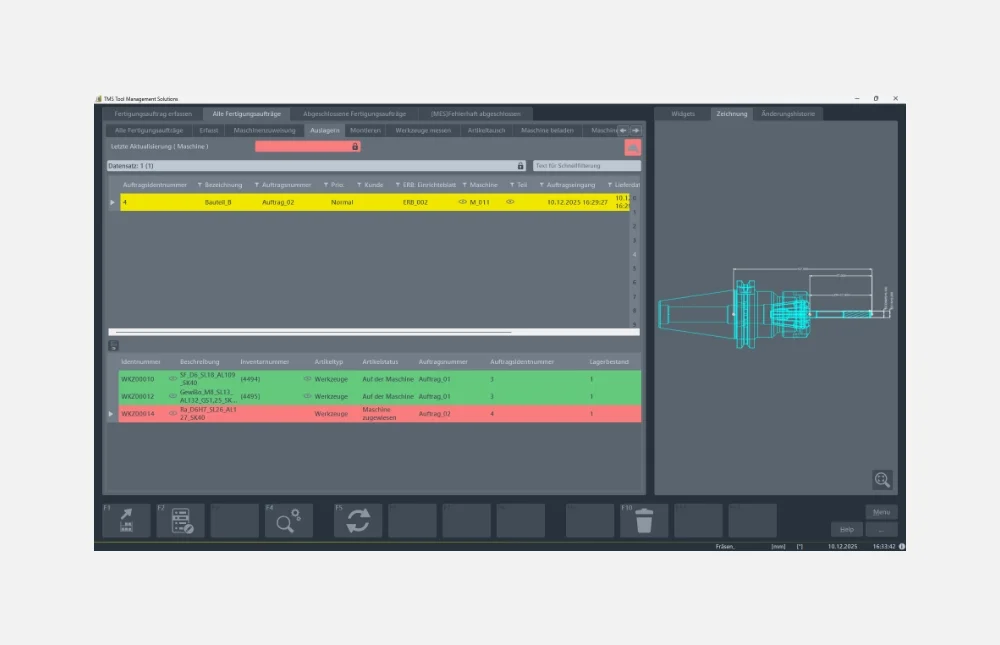

- Systematic management of production orders and set-up sheets

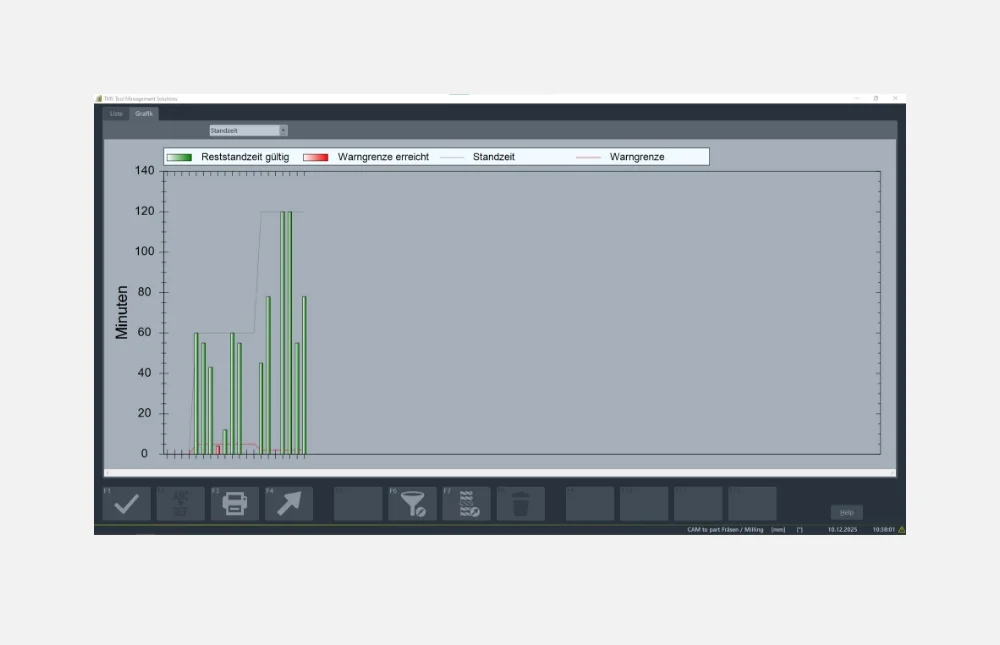

- Integrated tool life management

- Optional integration in ordering system incl. supplier management

- Smooth workflows in the production process