ZOLLER is the ideal partner for tool setting

This is a detailed analysis of the introduction of the »smile« tool presetter from ZOLLER at Five Straight, a company based in Kanzakigun, Hyogo Prefecture, Japan. The company's goal is to efficiently produce high-precision parts in the manufacturing industry.

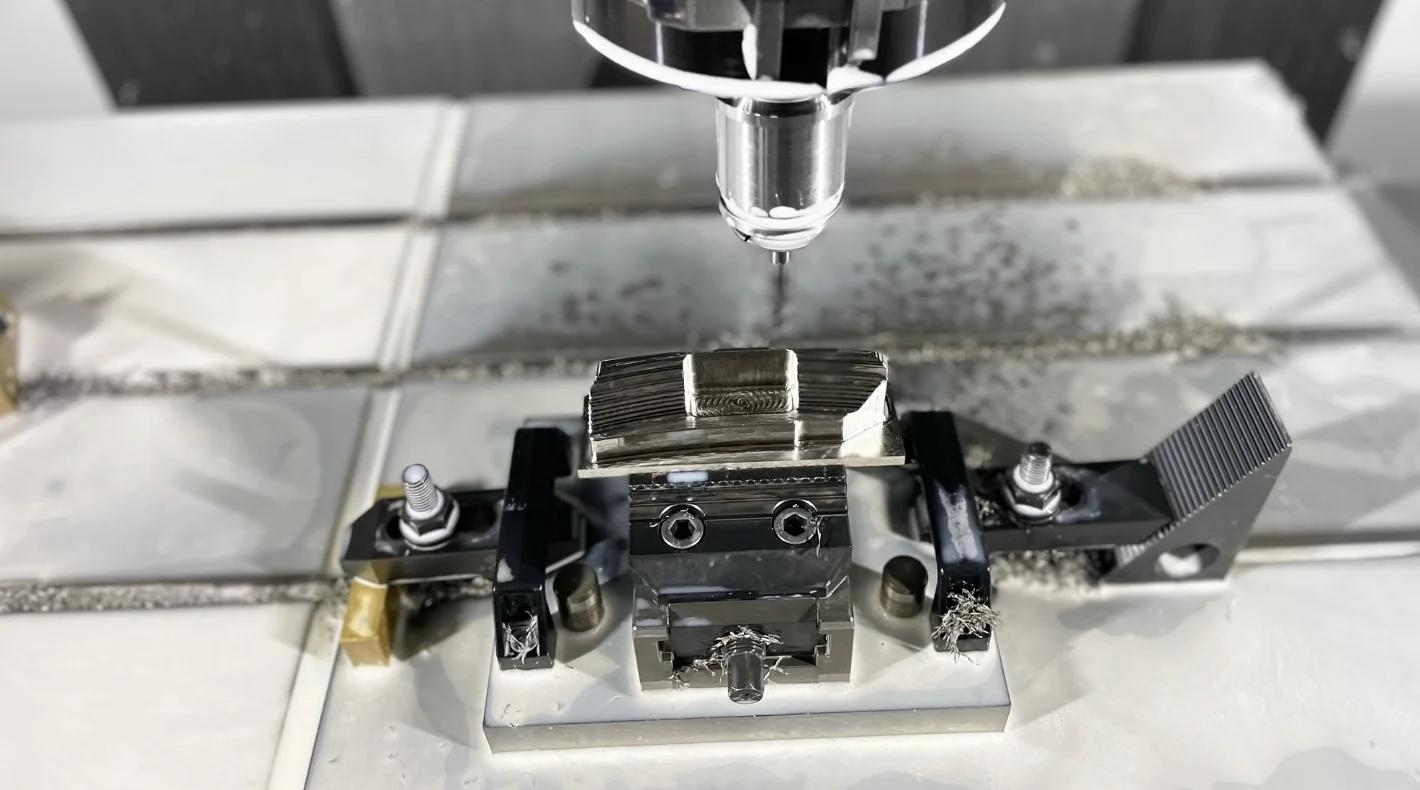

In order to carry out high-mix-medium-volume production (multiple industries, multiple materials) with a small number of employees, the company is constantly striving to streamline and optimize all processes. Specific challenges on the shop floor included dimensional errors and tool wear, as well as improper set-up procedures that directly led to poor quality and inefficiency. To solve these problems, Five Straight introduced the ZOLLER »smile« tool presetter.

Back to overview

Back to overview