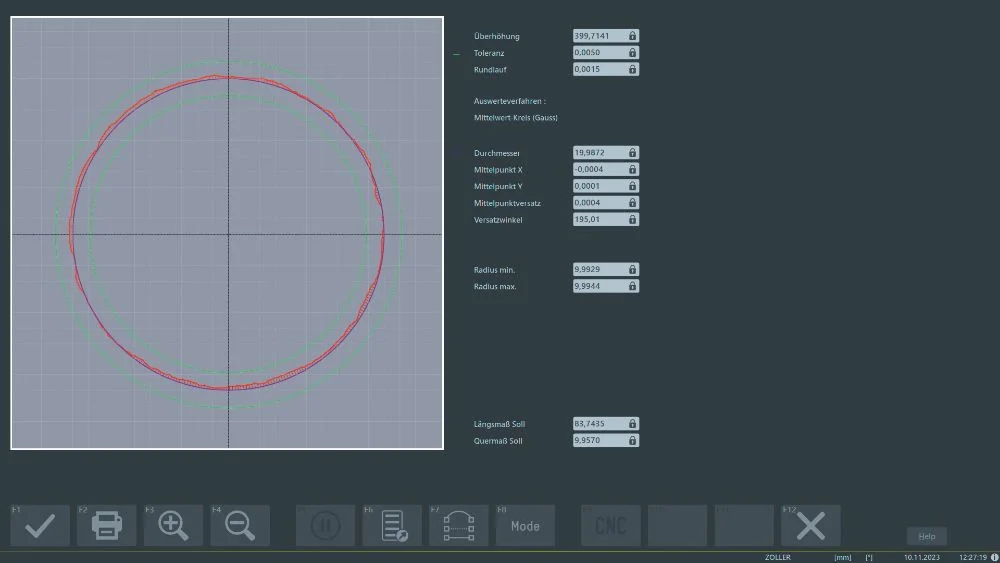

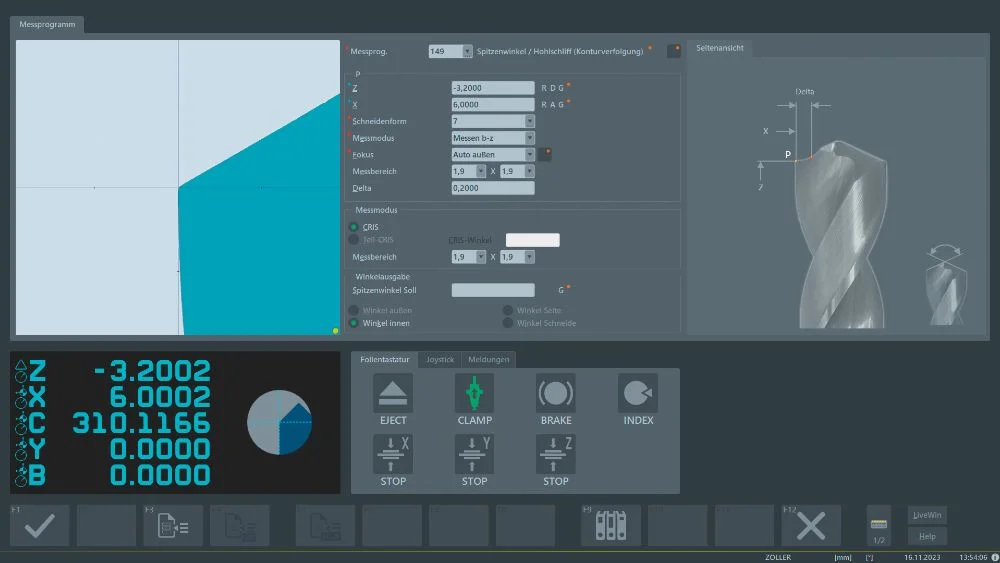

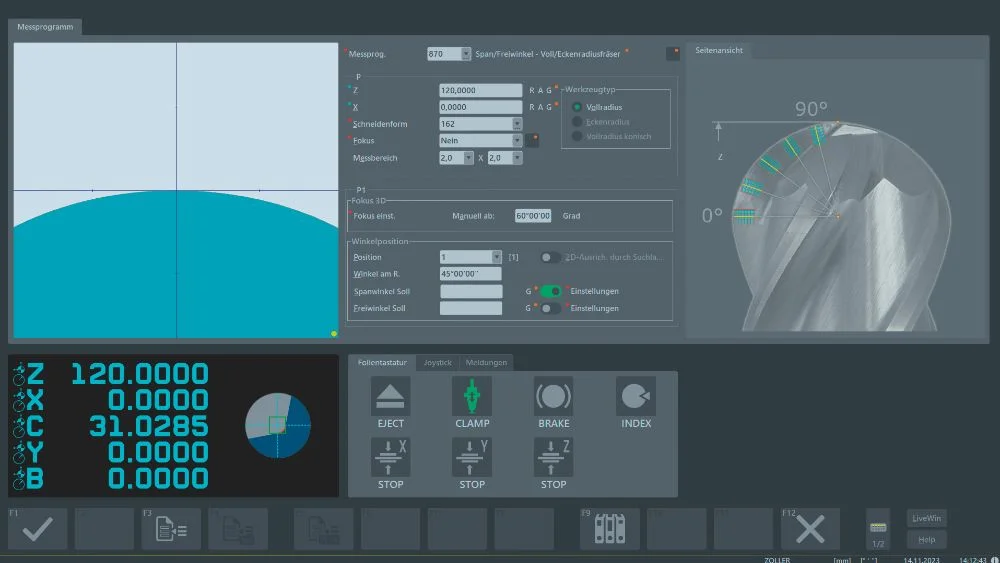

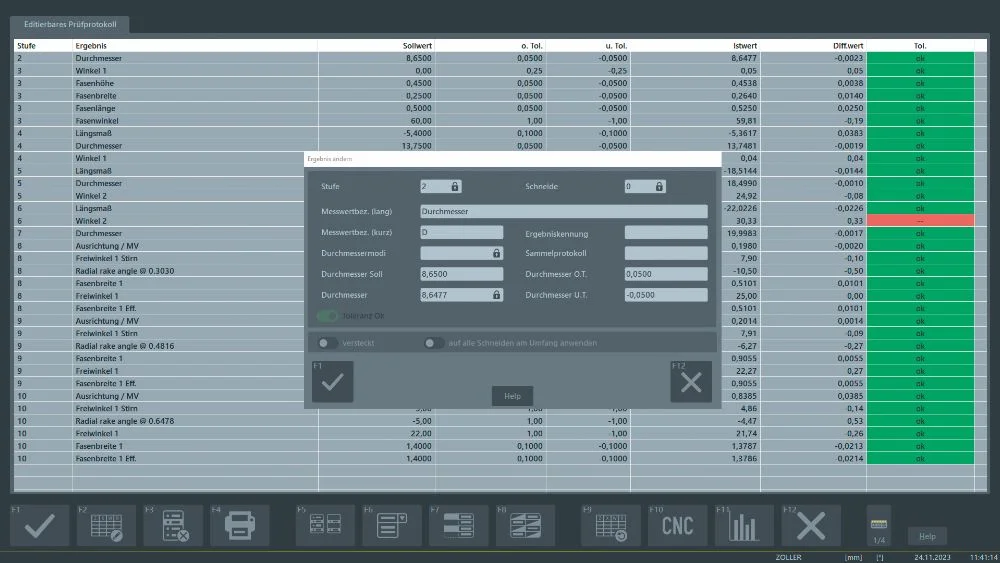

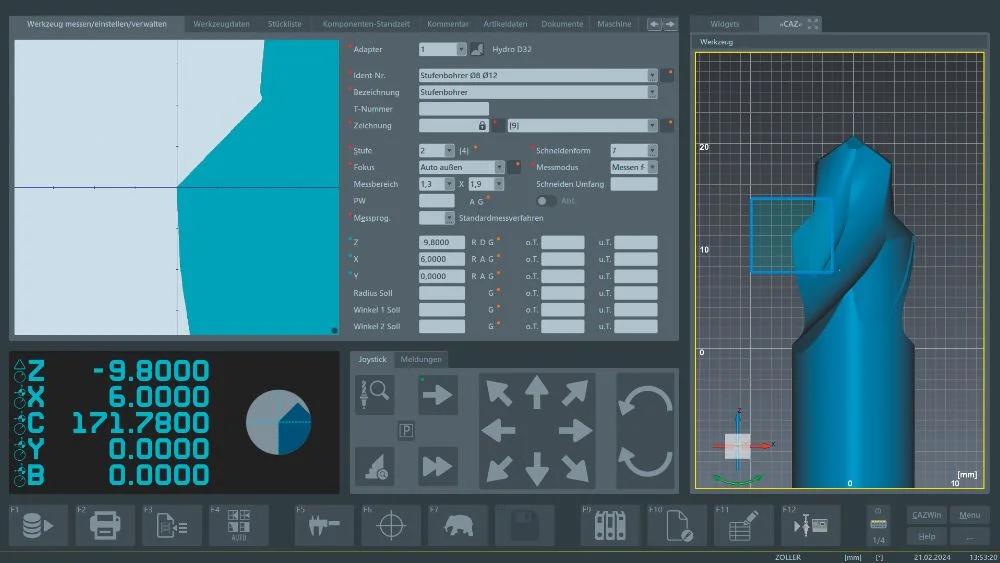

»expert« is the specialist for measurements on precision tools - based on the ZOLLER software »pilot 4.0«. The intelligent software generates the optimum measuring sequence from the selected parameters. Fully automatic, reproducible and with photorealistic parameter selection. The parameters to be measured can be selected easily, quickly and tool-specifically for the measuring program sequence using checkboxes. Simply select and confirm the parameters to be measured - and the measuring process starts.

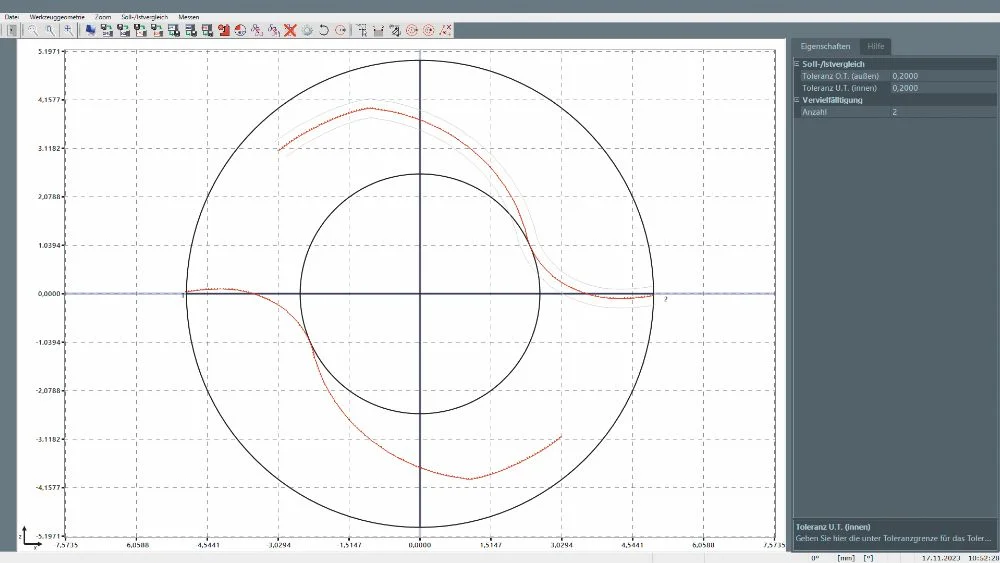

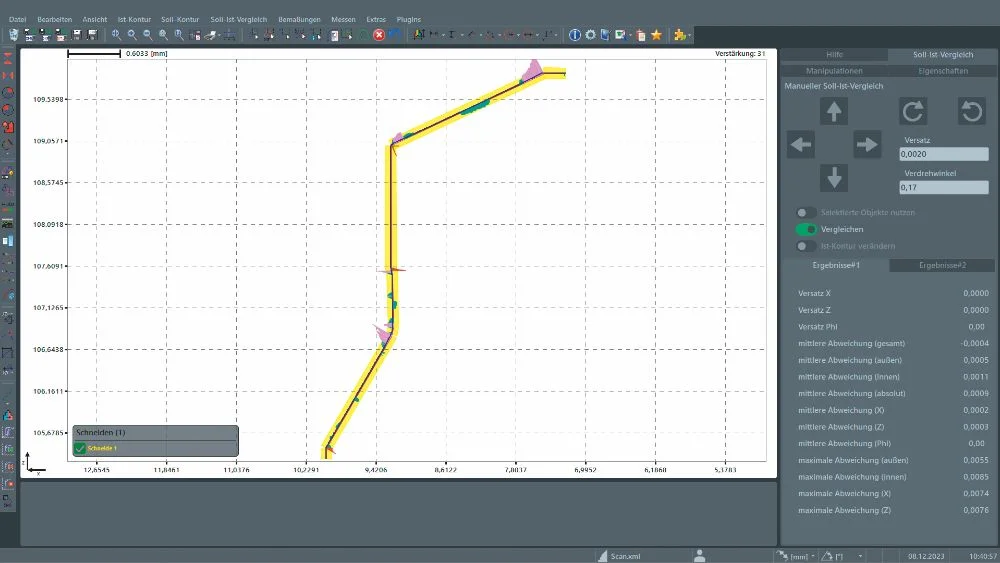

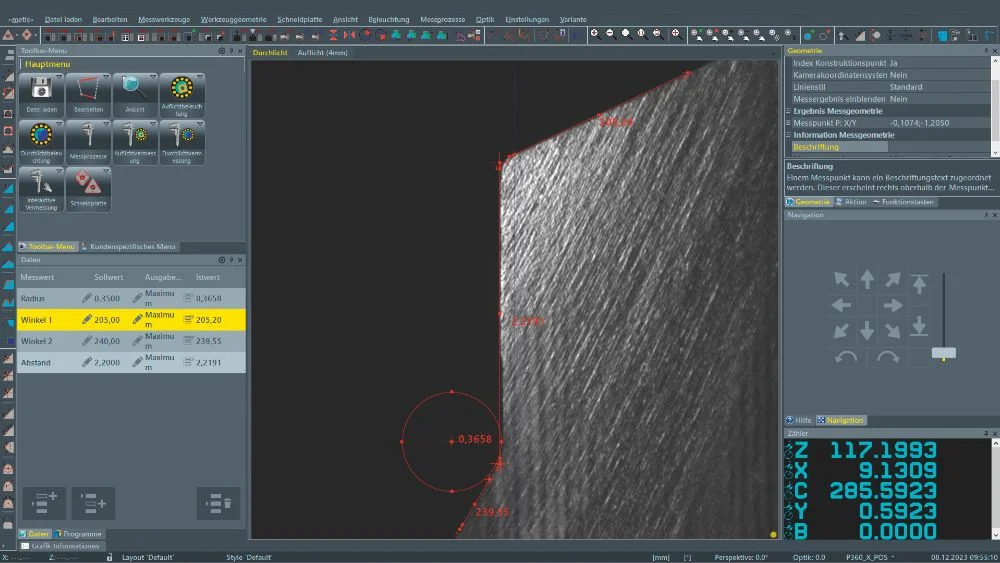

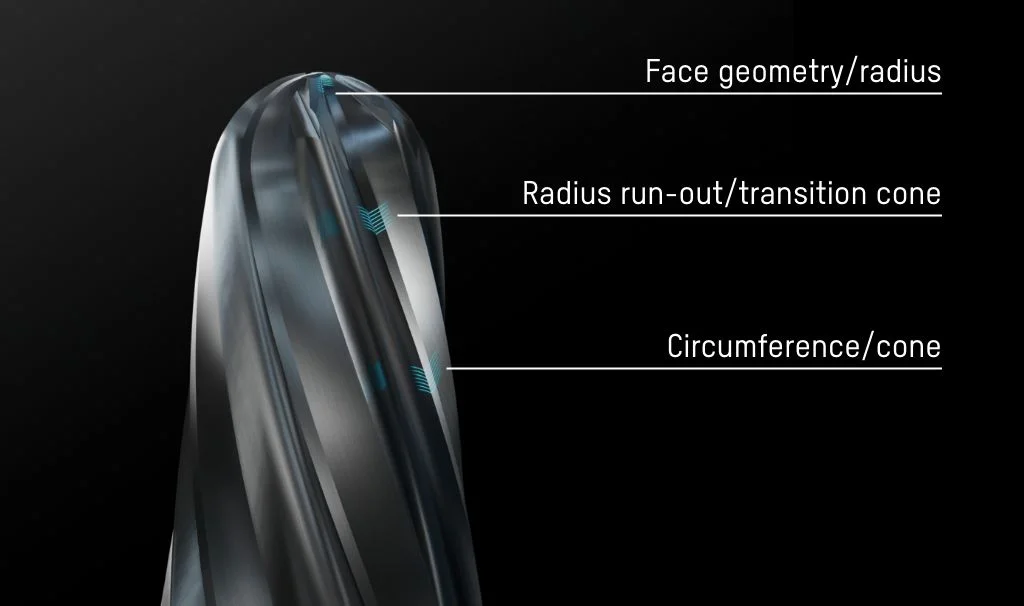

In order to achieve an optimum tool life as well as efficient and precise cutting performance of cutting tools, a defined preparation of the cutting edges is crucial. The control and optimization of cutting edge preparation and its reliable and detailed documentation are playing an increasingly important role here. ZOLLER »titan« with the CNC-controlled swiveling measuring sensor »zep« and the »skp« software measures a wide variety of cutting edge preparation forms quickly, contact-free and fully automatically.

Pioneering efficiency for your grinding shop

The greatest potential for efficiency lies outside the grinding machine: ZOLLER Solutions stand for your future - we make you more successful. Because those who manufacture faster and more efficiently operate more economically in order to be able to invest in the future. If economic progress is your goal, then ZOLLER is your partner.

Process optimization - μm-precisely networked