Once you have inserted the shrink fit chuck, the »masterPiece« setting adapter and the tool into the »redomatic«, the length stop is automatically set to match the target tool length. This gives you an accuracy of less than 10 μm when setting the target length. The measuring repeatability of the »redomatic« is the same as that of other ZOLLER presetting and measuring machines and is max. 2 μm.

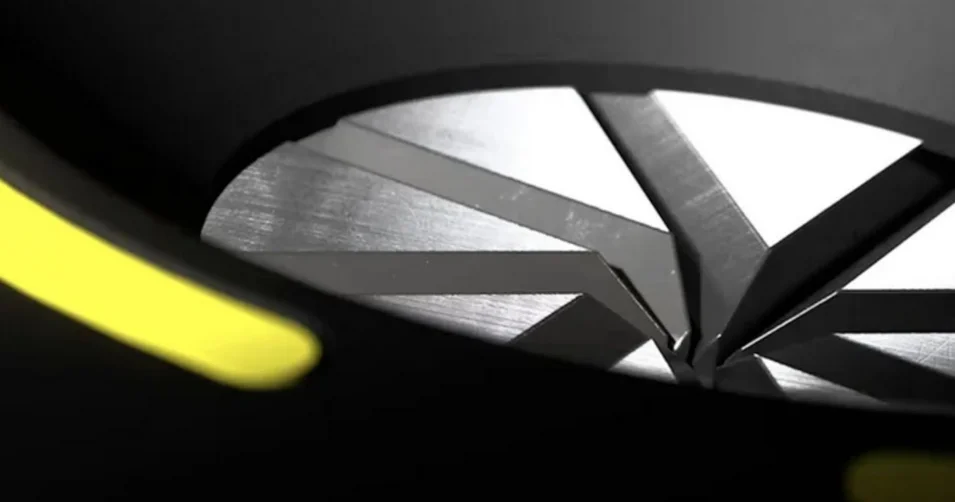

You have the option between our automatic induction coil with »varOct« shielding system and the manual version with shielding discs. Both coils are available in the 14 kVA version. The coil with shielding discs is optionally available as a 22 kVA coil for shrinking larger shrink chuck diameters D40 mm to D50 mm and reinforced shrink chucks (greater wall thickness).

Your appliance should be installed on a concrete or similar base plate with a maximum unevenness of 2 mm. The installation site should be equipped with compressed air, a power connection and a network connection. The device should be protected from sunlight, cold or warm air currents, magnetic fields and vibrations in order not to falsify the measurement results.

All components for the shrinking process are clearly and ergonomically arranged on our auxiliary unit. This provides the operating personnel with a comfortable working environment. With the »redomatic 600« model, the »sls« shrink guidance system on the auxiliary unit also uses LEDs to indicate the correct component for the upcoming work step. To achieve an even simpler and safer shrinking process, the cooling bells on both the »redomatic 400« and »redomatic 600« are available with the »coolbyLight« operator guidance system, which guides the operator through the cooling process using the LED color system.

We have various setting pins in our range, which can be selected as required. The device shows you exactly which pin you need to insert via the LED-controlled operator guidance of the »sls« shrink guide system on the auxiliary unit. The pins are simply and user-friendly screwed in with a thread, so they can be changed in just a few seconds.

With the »swomp« (shrinking without »masterPiece«) measuring program, it is possible to shrink all types of drilling tools quickly and reliably to a specific nominal length. It does not matter whether the tool is new or has been reground. During the shrinking process, the automatic length stop system »asza« is pre-positioned, the shrink chuck is heated and the length of the tool is set with high precision without the need for a setting adapter.