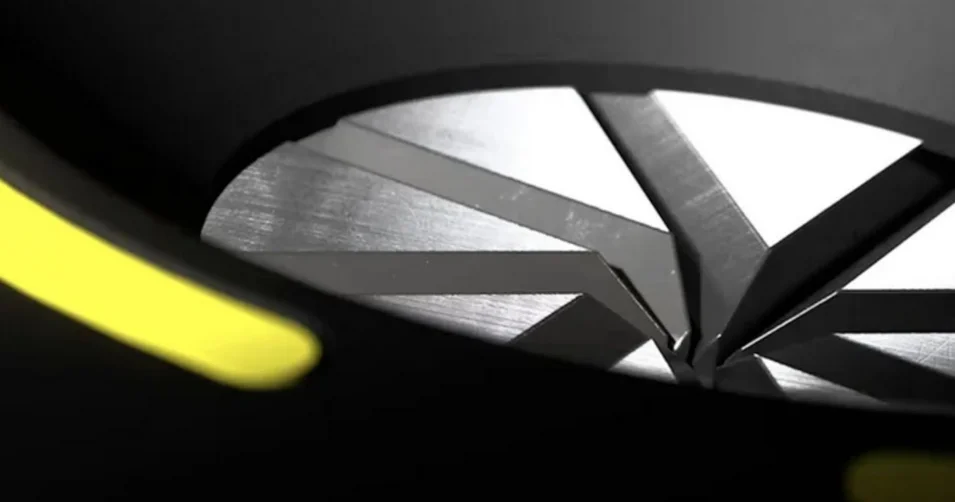

Insert the tool, press the button, done. This is how easy it is to power-clamp tools with the universal high-precision »ace« (all-clamping-element) spindle from ZOLLER - always with the same precision, μm-accurate and safe. The universal attachment holder changing system enables an exchange in less than 10 seconds between clamping systems such as SK, HSK, PSC, VDI, KM or hydraulic expansion. No wonder that this power-operated high-precision spindle has been delighting users worldwide for decades.

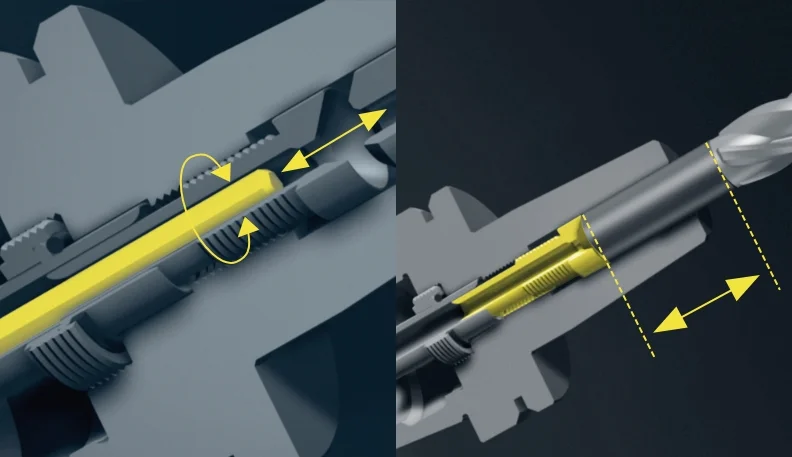

In the case of tools for minimum quantity lubrication (MQL), the coolant transfer piece must be positively connected to the shank end of the tool. Only then will you have full functionality and process reliability when manufacturing with MQL tools. ZOLLER technology guarantees you a secure and positive connection to the coolant supply - completely automatically.

For shrinking larger shrink fit chuck diameters D 40 mm to D 50 mm and reinforced shrink fit chucks (greater wall thickness). The 22 kVA induction coil can be operated quickly and ergonomically alternating with the 14 kVA induction coil via a quick-change interface. The 22 kVA induction coil with shielding disks in the diameter sizes D 16 mm to D 20 mm, D 25 mm to D 32 mm and D 40 mm to D 50 mm - these are optionally available in a split version.

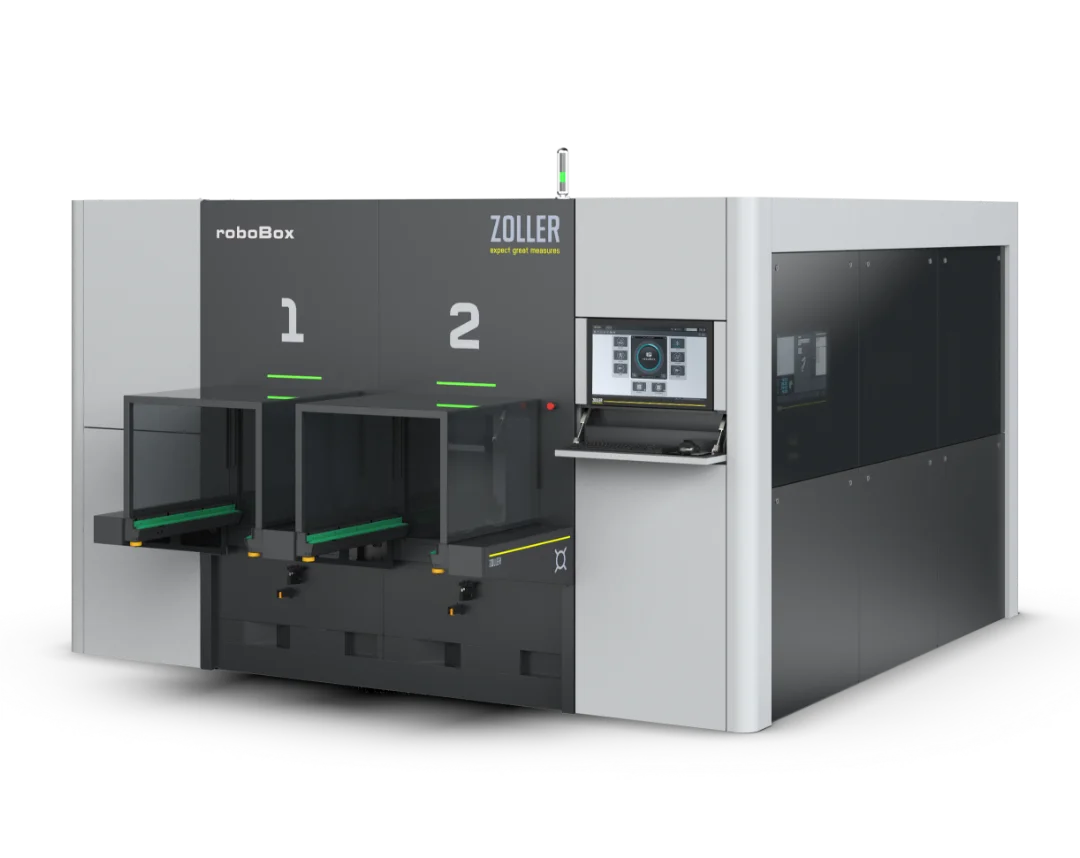

Automation system »roboBox«

If you use a lot of shrink-fit tools every day, you will immediately benefit from the »roboBox« automation system. With up to six modules, you can individually expand »roboBox« into a fully automated system for mounting, measuring and cooling tools. Your benefits: high throughput, high precision, high tool availability.

Even with the combination of the three modules measuring, shrinking and cooling, »roboBox« handles all shrinking processes independently. Work with shrink-fitted and precisely measured tools in series, fully automatically. Shrink tools that have reached their service life limit or are defective. ZOLLER »roboBox« can be easily integrated into any production line and quickly put into operation.